Multi-axial pressure cyclone-jet mixing pile driver and method for forming piles using the pile driver

A technology of mixing pile driver and cyclone, which is applied in the field of multi-axial pressure cyclone jet mixing pile driver, can solve the problems of increasing mechanical table shift and labor costs, increased mechanical table shift, unevenness, etc., and achieves a reduction in mechanical table Shift and labor costs, convenient and fast installation and movement, and uniform and dense cement and soil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

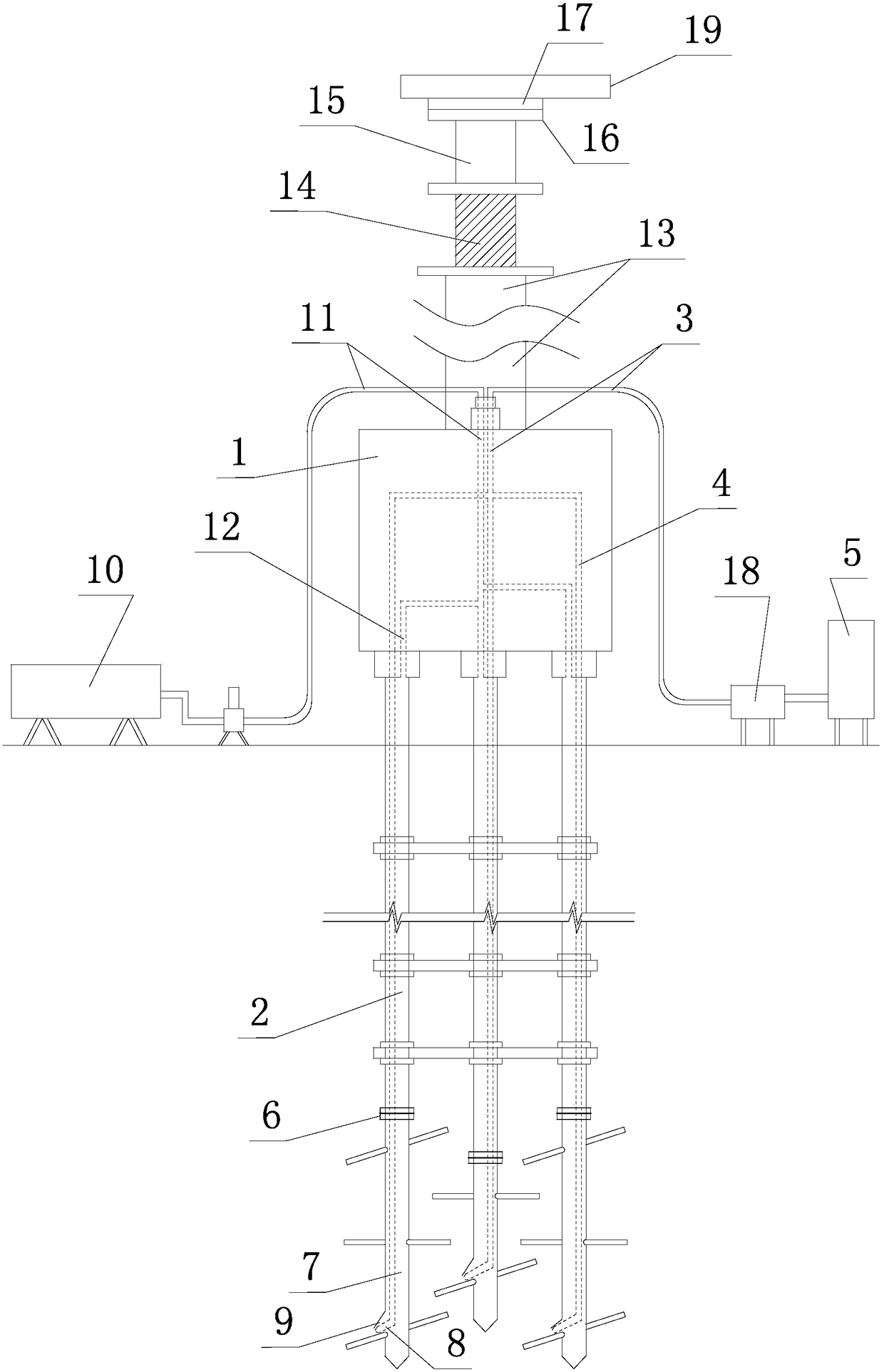

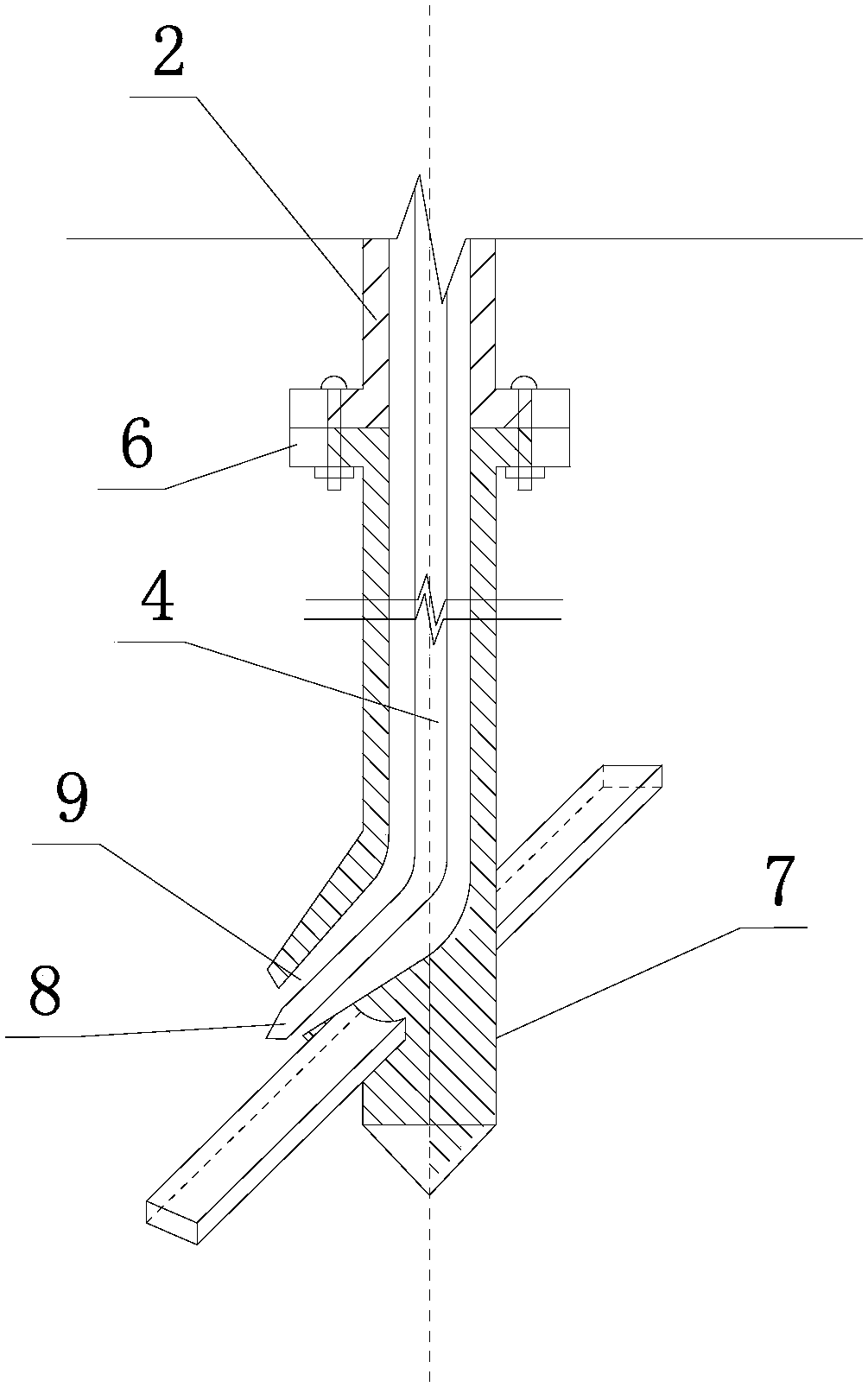

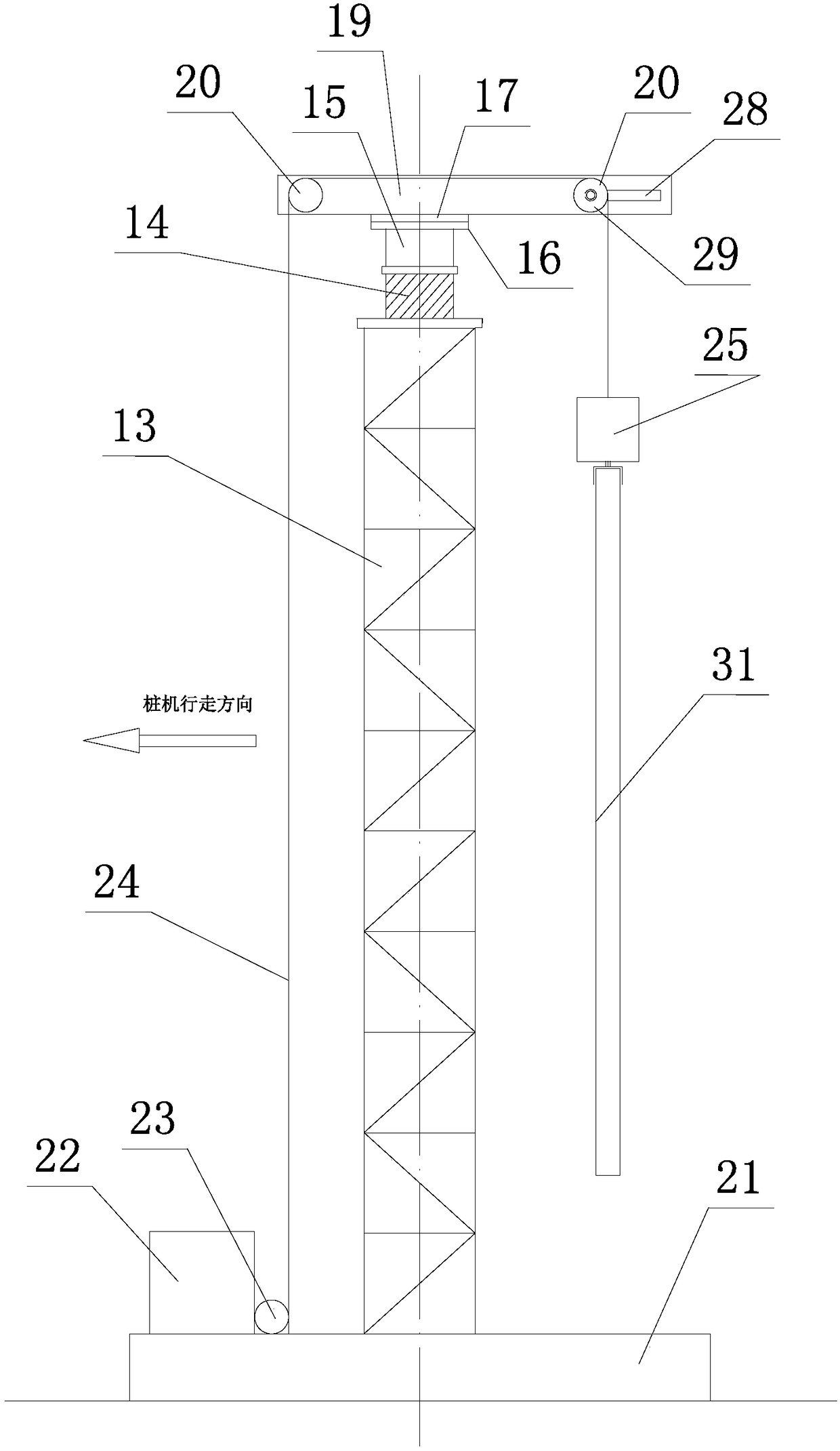

[0027] like figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 As shown, the multi-axis pressure cyclone-jet mixing pile driver of the present invention includes a pile frame 13, a power head 1, a plurality of parallel stirring shafts 2, a main slurry delivery pipe 3, a plurality of slurry delivery sub-pipes 4, and a slurry delivery pump 18 and slurry mixer 5. The power head 1 is installed on the pile frame 13, the stirring shaft 2 is hollow tubular and a plurality of stirring shafts 2 are installed at the lower end of the power head 1, each stirring shaft 2 is fixed with a stirring blade with a stirring blade at the lower end of the flange plate 6 head 7. Each mixing head 7 is fixed with a spray nozzle 8, and each spray nozzle 8 communicates with the slurry pump 18 through the slurry delivery branch pipe 4 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com