Cover glass for flat panel displays and method for producing the same

A flat-panel display and manufacturing method technology, applied to glass manufacturing equipment, chemical instruments and methods, manufacturing tools, etc., can solve problems such as edge gaps, and achieve the effects of preventing deterioration of design, high design, and good design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

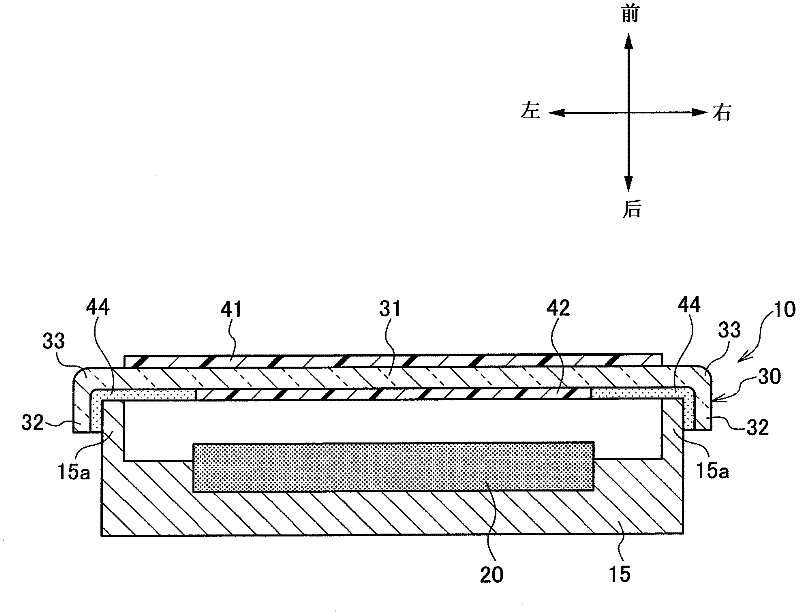

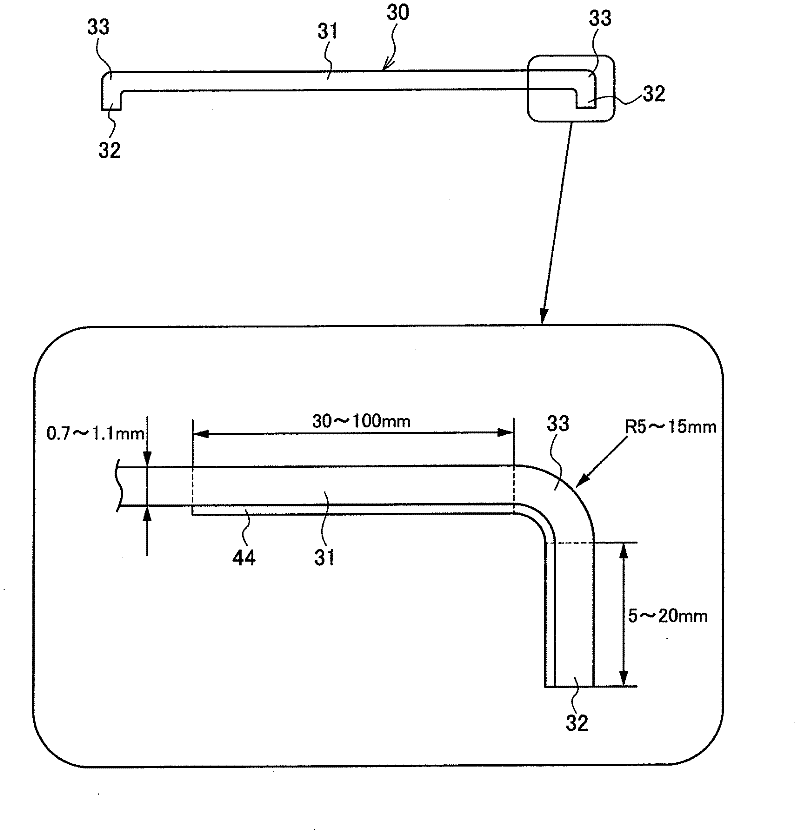

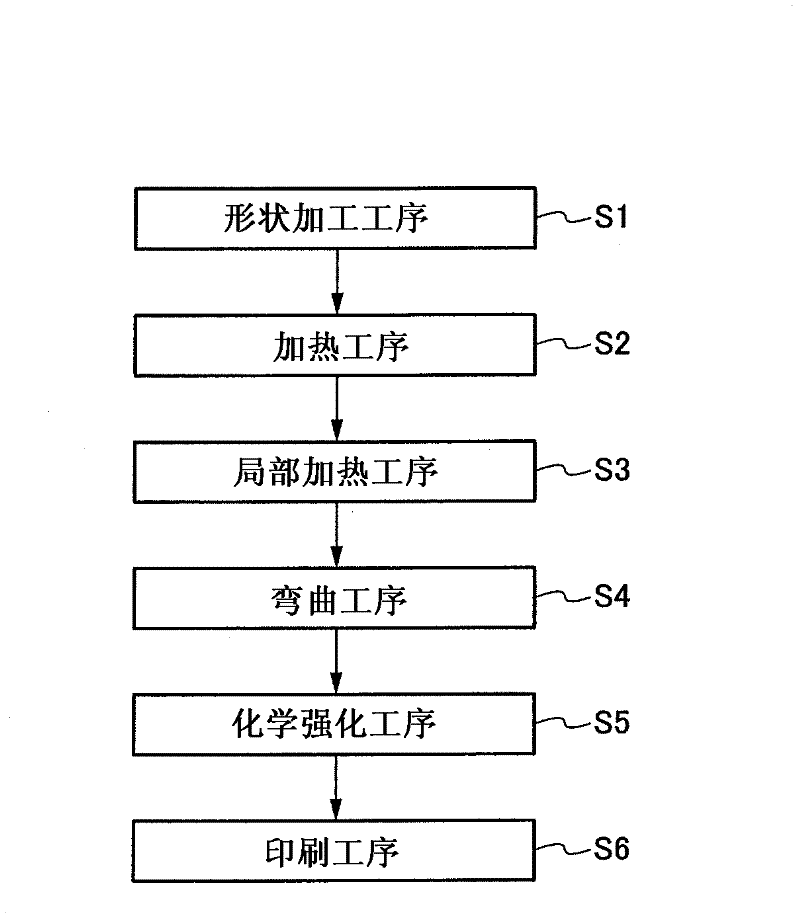

[0082] Next, the cover glass for flat panel displays of this invention and its manufacturing method are demonstrated. figure 1 It is a cross-sectional view of a display device equipped with a cover glass for a flat panel display according to an embodiment of the present invention, figure 2 yes figure 1 An enlarged view of a cover glass for a flat panel display.

[0083] First, refer to figure 1 An embodiment of a flat panel display device (hereinafter, may be simply referred to as a display device) using the cover glass for a flat panel display of the present invention (hereinafter, may be simply referred to as a cover glass.) will be described. In the following description, front, rear, left, and right are based on the arrow directions in the drawings.

[0084] Such as figure 1 As shown, the display device 10 roughly includes a display panel 20 provided in the casing 15 , and a cover glass 30 provided so as to cover the entire surface of the display panel 20 and surround...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com