Ball joint and method for fastening a sealing bellows to a ball joint

一种密封波纹管、球窝关节的技术,应用在球窝关节以及用于在球窝关节上固定密封波纹管领域,达到腐蚀危险小的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

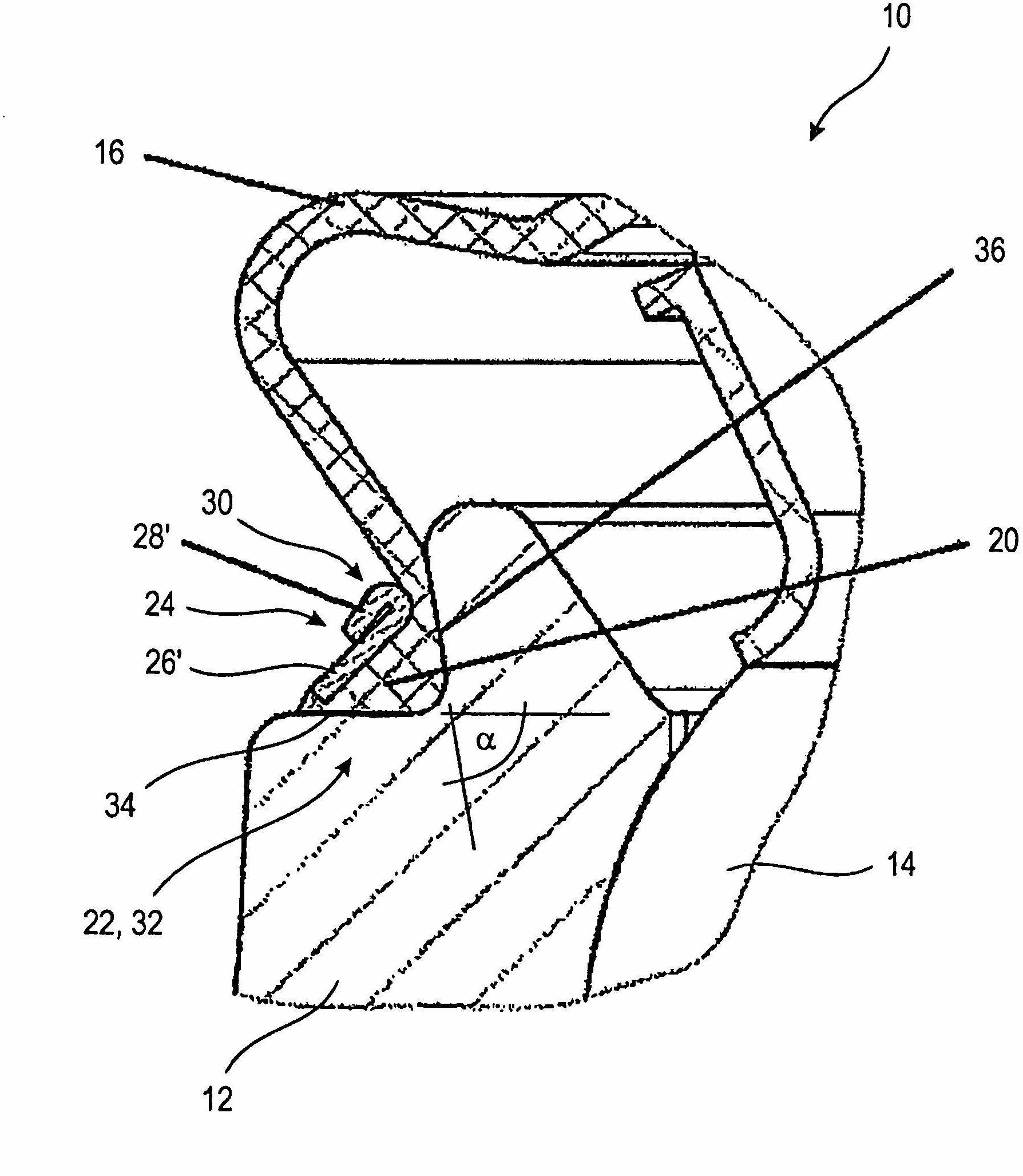

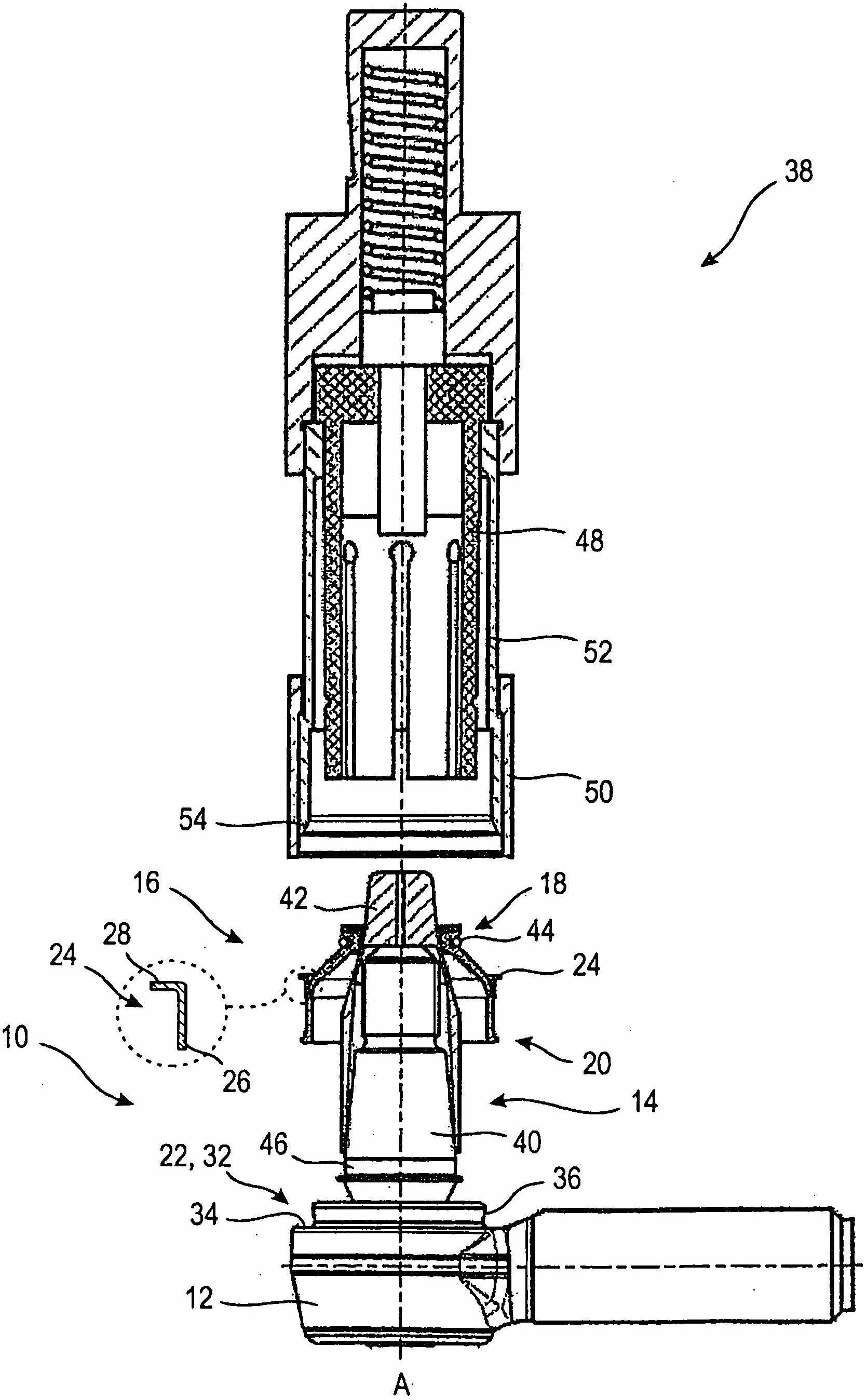

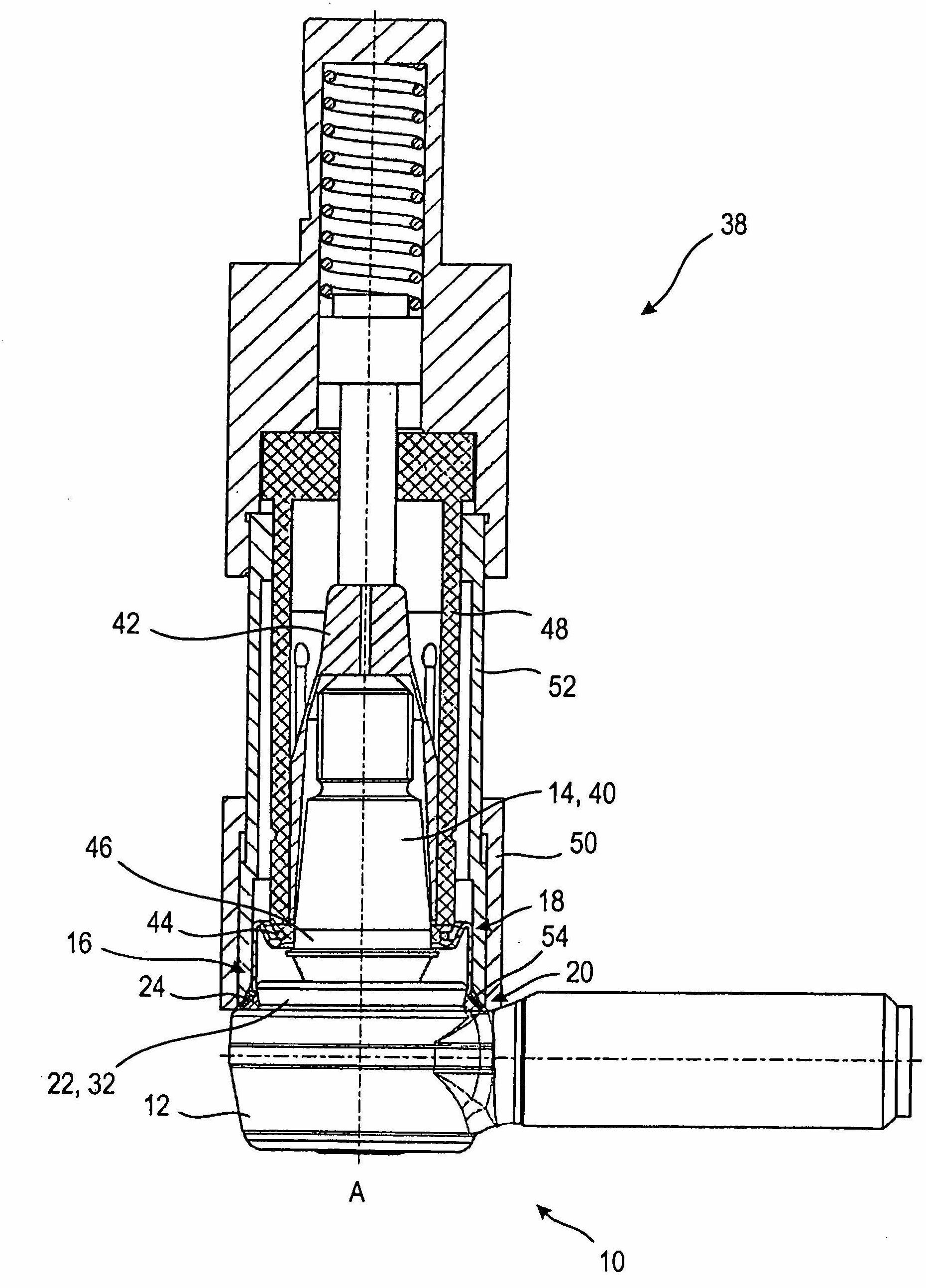

[0021] figure 1 Shown is a ball and socket joint 10 comprising a joint housing 12, a spherical journal 14 and an already assembled sealing bellows 16, the ball head of which is pivotally accommodated in the joint housing 12, the sealing bellows has, with respect to the longitudinal axis A of the journal, an axial first bellows end 18 fixed on the spherical journal 14 (see figure 2 and 3 ) and a second axial bellows end 20 fixed on the joint housing 12 . For fastening the sealing bellows 16 , the joint housing 12 has a bellows seat 22 which forms both a radial and an axial stop for the second bellows end 20 . A closed retaining ring 24 is provided at a distance from the joint housing 12 , which acts on the sealing bellows 16 radially inwardly and holds it against the bellows seat 22 .

[0022] The retaining ring 24 is here a separate, plastically deformed metal ring, preferably made of sheet metal, which substantially surrounds the second bellows end 20 .

[0023] Before f...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap