Drive belts for transmissions with convex pulley pulleys

A transmission belt and continuously variable transmission technology, applied in the field of transmission belts, can solve problems such as unbalanced distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

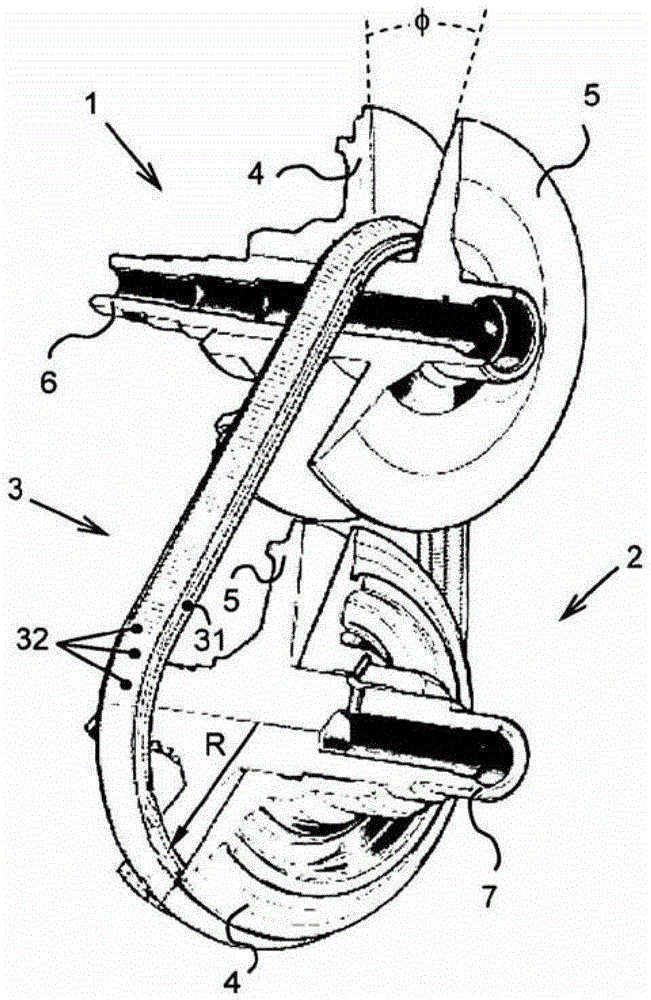

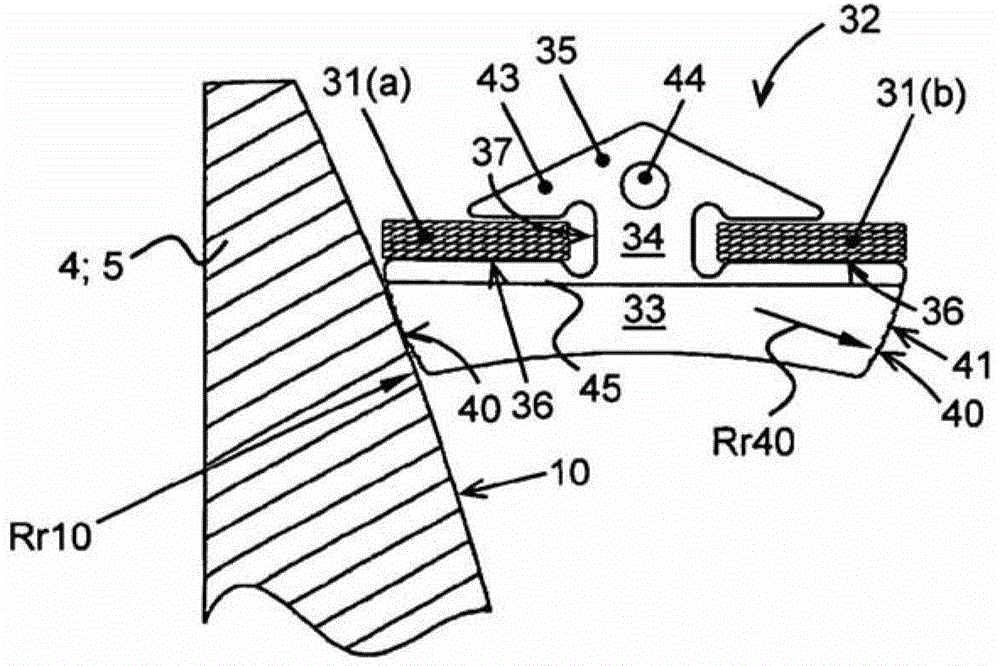

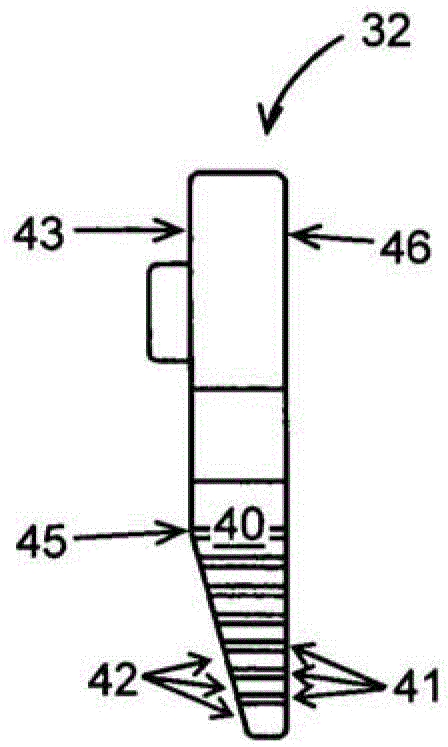

[0017] figure 1 A view of the main parts of a continuously variable transmission according to the prior art is schematically shown. Said known transmission comprises a first pulley 1 on a transmission input shaft 6 drivable by an engine (not shown) with a first (force) couple Tp, and a load (not shown) with a second couple Ts ) The second pulley 2 on the transmission output shaft 7. Both pulleys 1, 2 are provided with a substantially conical pulley disc 5 fixed invariably to the respective pulley shaft 6, 7 and provided with a shaft displaceable relative to said shaft 6, 7 in the axial direction. The same generally conical pulley wheel 4. The drive belt 3 is clamped between the pulley pulleys 4 , 5 of the two pulleys 1 , 2 , this drive belt in each case describes a path in the form of an approximately circular arc, ie a running radius R. Mechanical power can be transmitted between the two pulley shafts 6, 7 by means of the friction between the transmission belt 3 and the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com