A cutting device for lithium-ion battery diaphragm that is convenient for quick cutting

A lithium-ion battery and rapid cutting technology, which is applied in metal processing and other directions, can solve the problems of surface wrinkles of the diaphragm, diaphragm stained with dust, and difficult collection, etc., to achieve the effect of reducing the contact area, high cutting efficiency, and good cutting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

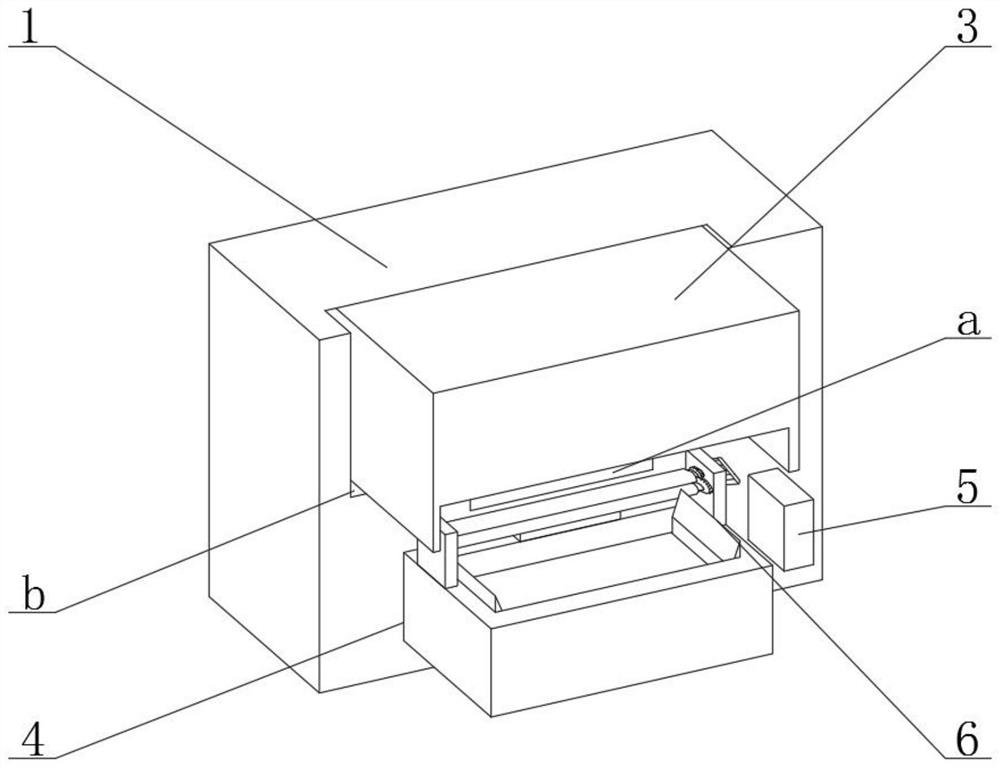

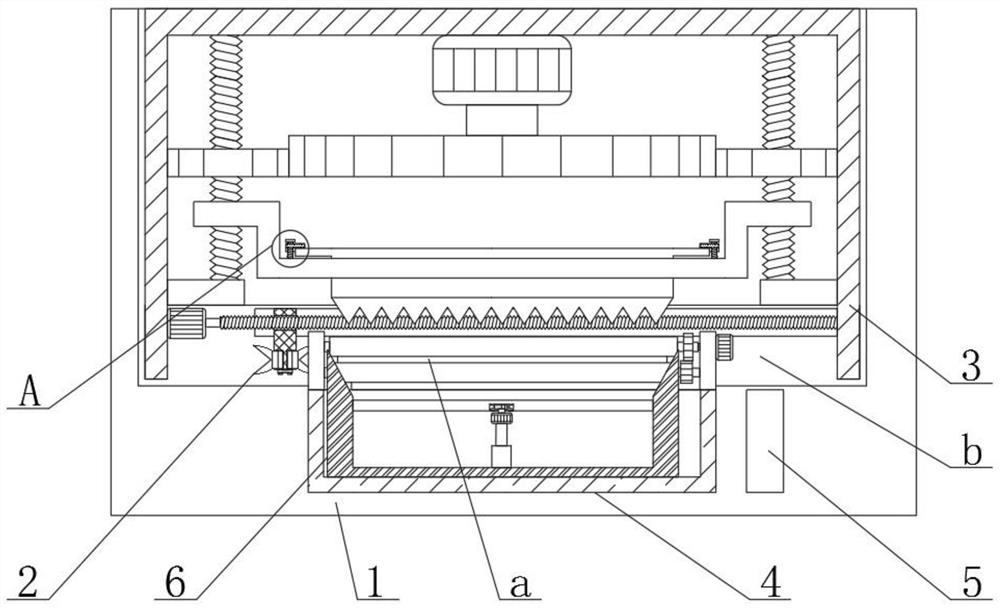

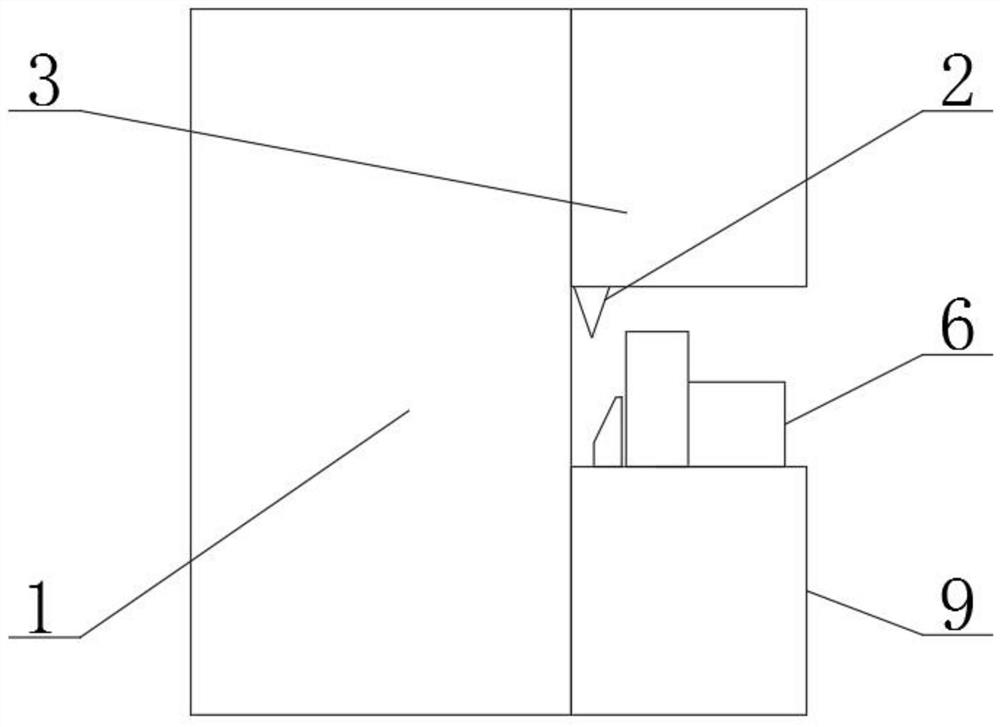

[0031] see figure 1 , figure 2 , image 3 , Figure 4 , Image 6 , Figure 7 , Figure 8 , Figure 9 and Figure 10 , the present invention provides a technical solution:

[0032]A cutting device for a lithium-ion battery diaphragm that is convenient for quick cutting, comprising a shearing machine 1, a cutting device 2, a collecting device 4 and an anti-wrinkle device 6, the front end of the shearing machine 1 is provided with a groove b, and the inside of the groove b is fixed A fixed box 3 is connected, and the inside of the fixed box 3 is fixedly connected with a cutting device 2, and the cutting device 2 includes a slider 201, a first blade 202, a third threaded shaft 203, a rotating block 204, a first threaded shaft 205 and a first motor 206 , the inner side of the left end surface of the fixed box 3 is fixedly connected with the first motor 206, the main shaft end of the first motor 206 is fixedly connected with the first threaded shaft 205, and the first threa...

Embodiment 2

[0036] see figure 1 , figure 2 , image 3 , Figure 5 , Figure 7 , Figure 8 , Figure 9 and Figure 10 , the present invention provides a technical solution:

[0037] A cutting device for a lithium-ion battery diaphragm that is convenient for quick cutting, comprising a shearing machine 1, a cutting device 2, a collecting device 4 and an anti-wrinkle device 6, the front end of the shearing machine 1 is provided with a groove b, and the inside of the groove b is fixed Be connected with fixed box 3, fixed box 3 insides are fixedly connected with cutting device 2, and cutting device 2 comprises fixed frame 207, knife rest 208, the second blade 209, positioning frame 210, the 4th screw shaft 211, the 2nd motor 212, the 2nd A driving gear 213, a first driven gear 214 and a second threaded shaft 215, the inner side of the top surface of the fixed box 3 is fixedly connected with a second motor 212, the main shaft end of the second motor 212 is fixedly connected with the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com