Copper and copper alloy strip hot-rolling online surface scale collection device

A technology of copper alloy strip and collecting device, which is applied in metal rolling, metal rolling, workpiece surface treatment equipment, etc., can solve the problems of increasing physical labor of workers, polluting cooling water, pressing into processed copper plates, etc., and achieves saving Equipment space, increase kinetic energy consumption, avoid pollution effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

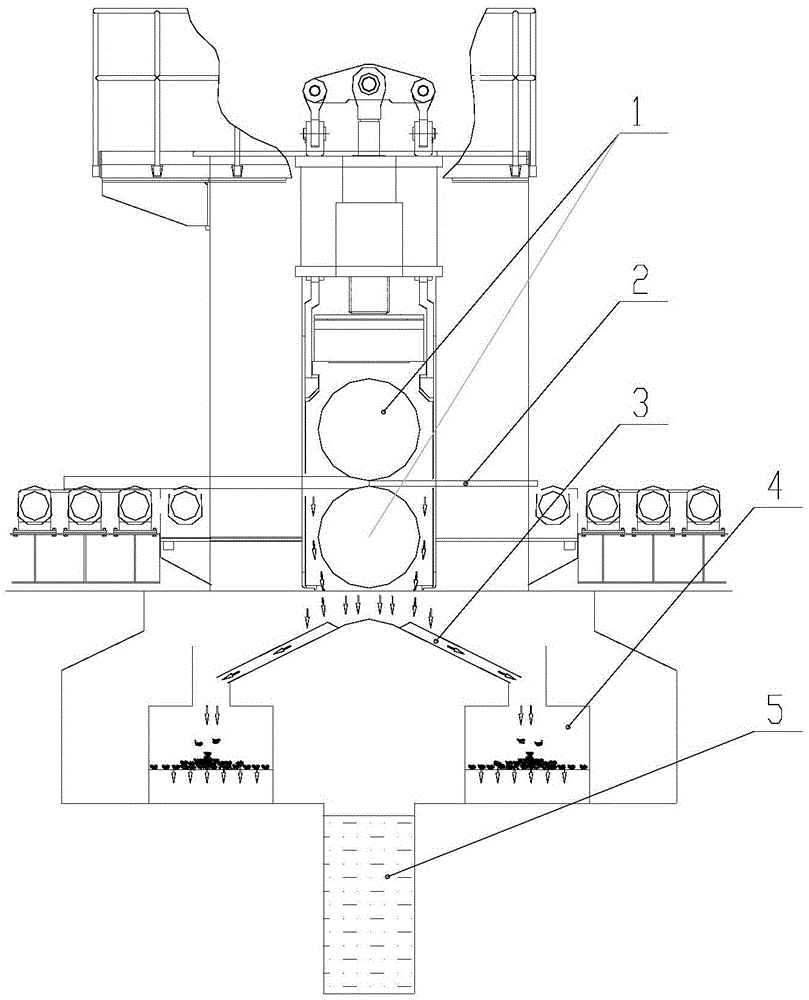

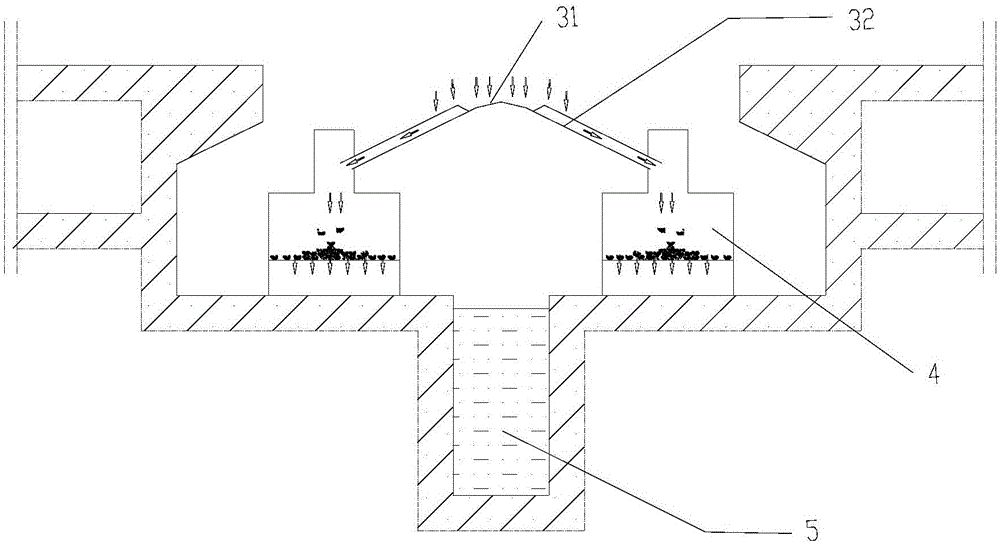

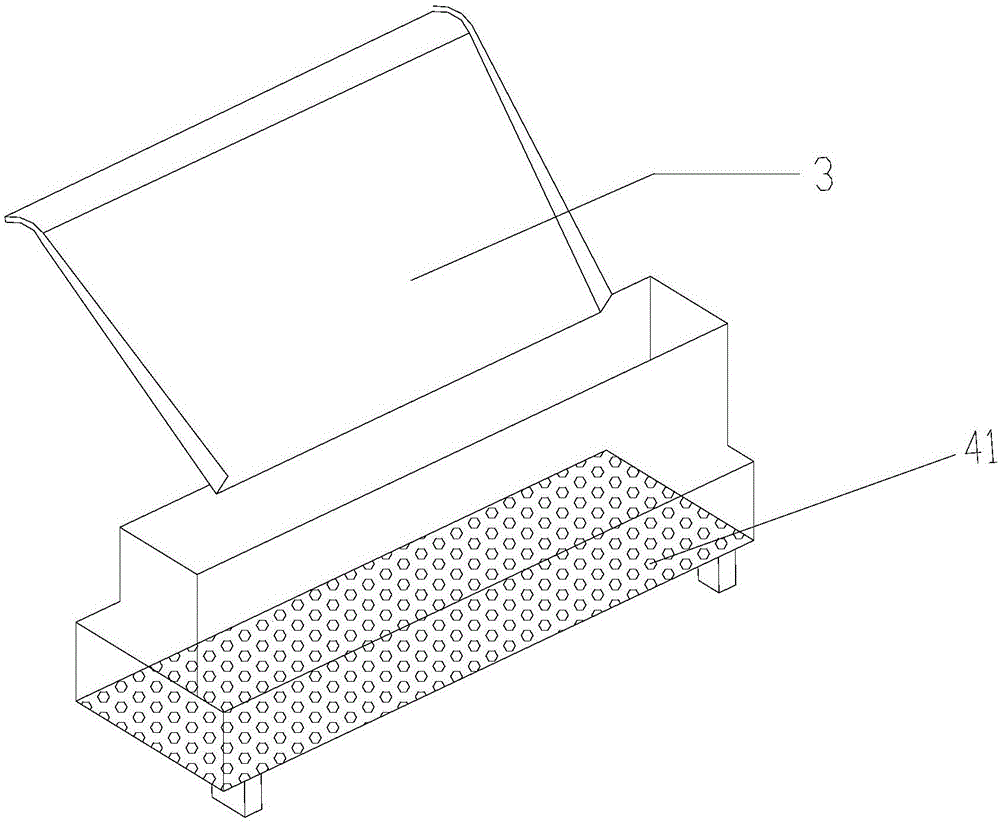

[0024] refer to figure 1 and figure 2 , copper and copper alloy strip hot-rolled on-line surface oxide scale collection device, including a hot-rolling mill frame, a pair of rollers 1 arranged up and down are arranged horizontally on the hot-rolling mill frame, and the upper and lower rollers 1 are respectively crimped on the strip The upper and lower surfaces of the material 2; the roll 1 is provided with a cooling injection pipeline for spraying the cooling medium to the roll, and the cooling injection pipeline is connected with the circulation pool through a delivery pipeline; a pair of the rolls below have A effusion pool for collecting cooling medium, the bottom of the effusion pool is connected to the circulation pool through a return pipe, and a medium guide groove 3 for draining the cooling medium to both sides is provided under the roll 1 , the top of the medium diversion groove 3 has an arc segment 31, and the two ends of the arc segment 31 are provided with an inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com