Electrolyte infiltration method of soft package battery cell

A soft-pack battery and electrolyte technology, applied in secondary batteries, battery pack components, non-aqueous electrolyte batteries, etc., can solve the problems of affecting production efficiency, high energy consumption, and high equipment requirements, shortening the soaking time, reducing Production energy consumption, the effect of improving the infiltration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

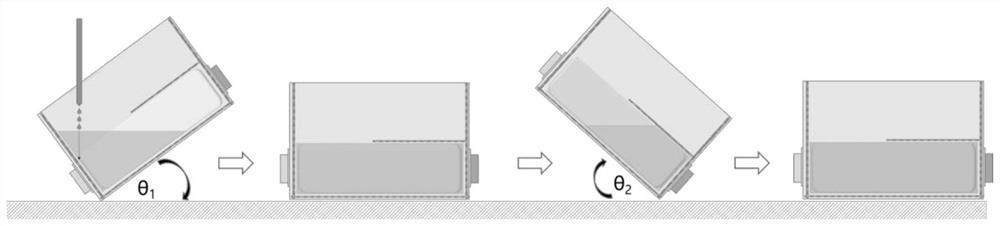

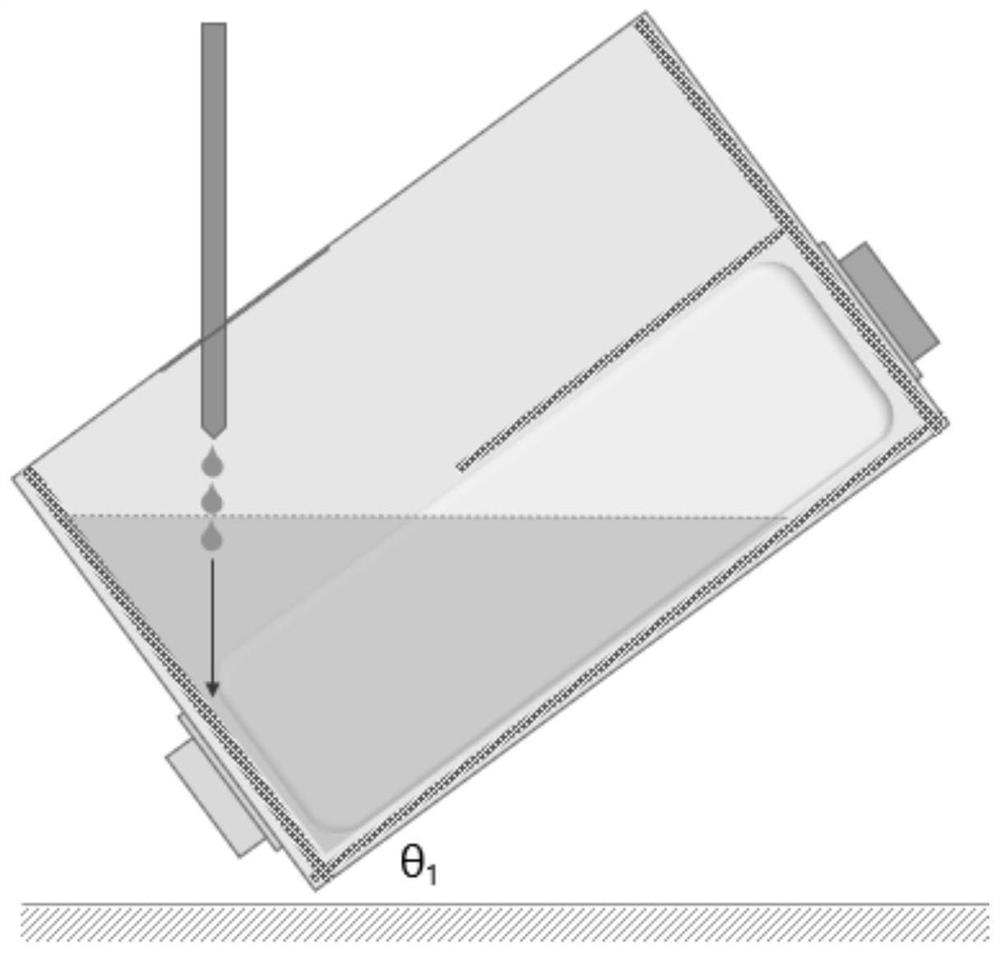

[0080] This embodiment provides an electrolyte infiltration method for a pouch battery cell, and the electrolyte infiltration method includes:

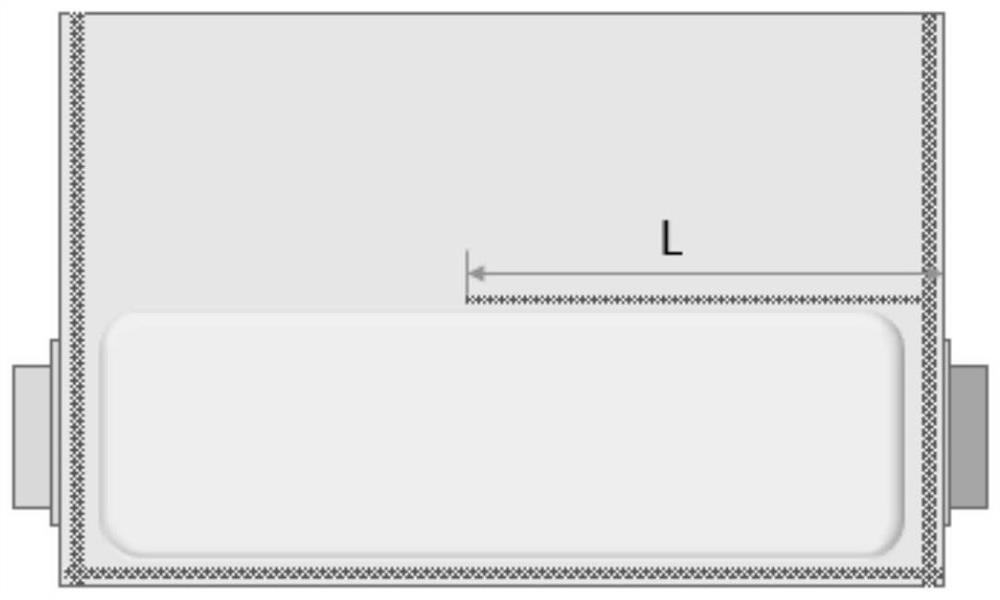

[0081] (1) Encapsulate the battery and reserve a liquid injection port. The packaged battery includes a packaging film and a battery body and an air bag of the packaging film arranged side by side inside the packaging film. The length direction of the battery main body is in line with the The side where the liquid injection port is located is parallel, the width direction of the main body of the battery cell is perpendicular to the side where the liquid injection port is located, and the length of the packaging film air bag is 0.8 times the width of the main body of the battery cell. The length of the battery core body is L 1 , the heat seal length L between the main body of the cell and the air bag of the packaging film 2 The seal, the heat-sealed part is far away from the horizontal plane, the unheated part is close to the horizont...

Embodiment 2

[0086] This embodiment provides an electrolyte infiltration method for a pouch battery cell, and the electrolyte infiltration method includes:

[0087] (1) Encapsulate the battery and reserve a liquid injection port. The packaged battery includes a packaging film and a battery body and an air bag of the packaging film arranged side by side inside the packaging film. The length direction of the battery main body is in line with the The side where the liquid injection port is located is parallel, the width direction of the main body of the battery cell is perpendicular to the side where the liquid injection port is located, and the length of the packaging film air bag is 1.0 times the width of the main body of the battery cell. The length of the battery core body is L 1 , the heat seal length L between the main body of the cell and the air bag of the packaging film 2 The seal, the heat-sealed part is far away from the horizontal plane, the unheated part is close to the horizont...

Embodiment 3

[0092] This embodiment provides an electrolyte infiltration method for a pouch battery cell, and the electrolyte infiltration method includes:

[0093] (1) Encapsulate the battery and reserve a liquid injection port. The packaged battery includes a packaging film and a battery body and an air bag of the packaging film arranged side by side inside the packaging film. The length direction of the battery main body is in line with the The side where the liquid injection port is located is parallel, the width direction of the main body of the battery cell is perpendicular to the side where the liquid injection port is located, and the length of the packaging film air bag is 1.2 times the width of the main body of the battery cell. The length of the battery core body is L 1 , the heat seal length L between the main body of the cell and the air bag of the packaging film 2 The seal, the heat-sealed part is far away from the horizontal plane, the unheated part is close to the horizont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com