Method and device for binding optic disc base board, and liquid matter supply method

A technology for bonding devices and plate-shaped objects, which is applied to optical recording/reproduction, devices for coating liquid on the surface, optical discs, etc., which can solve the problems of small contact area and hollowness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

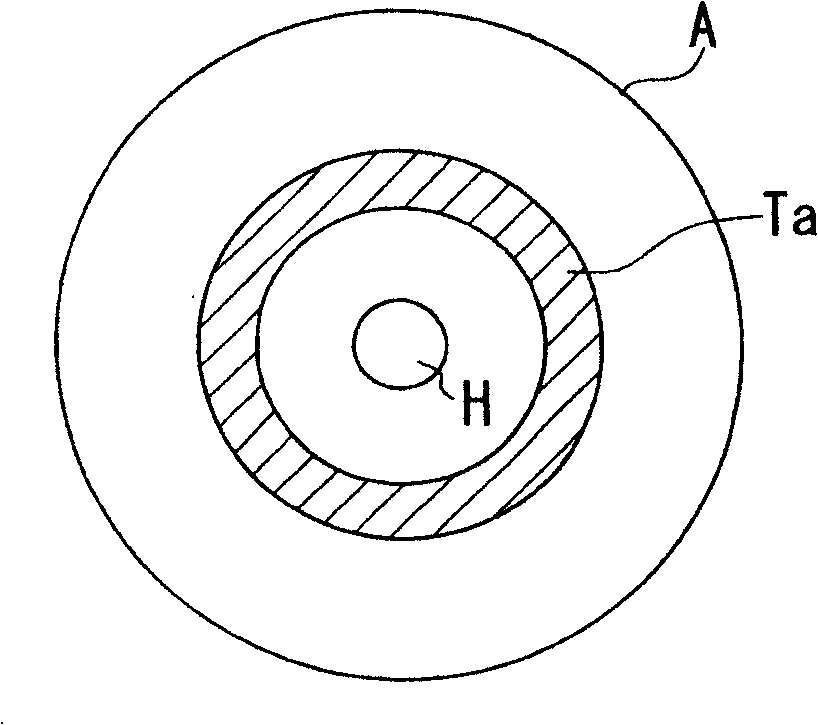

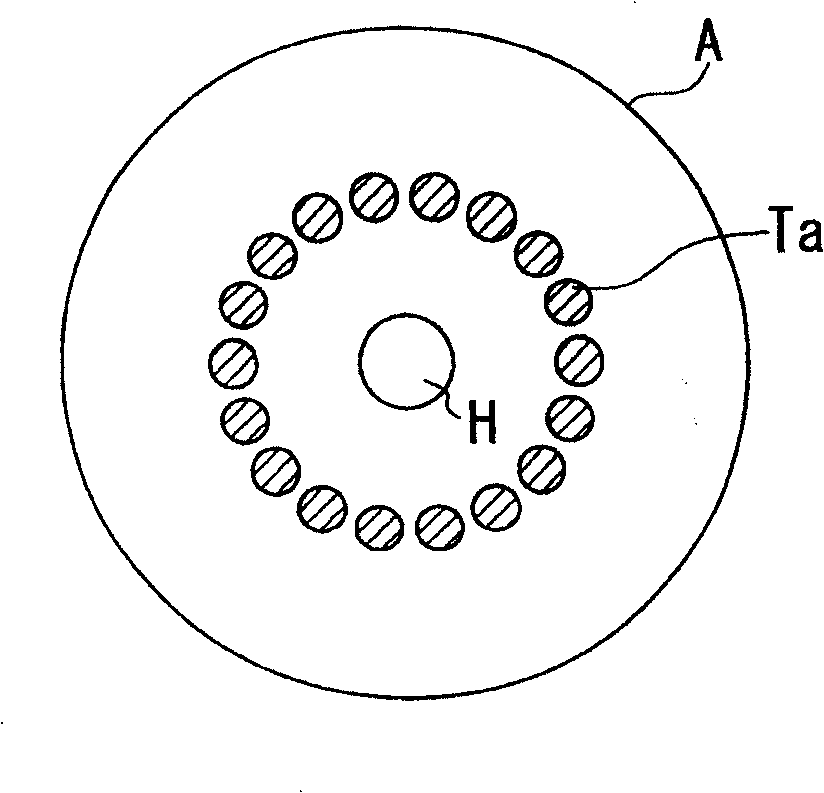

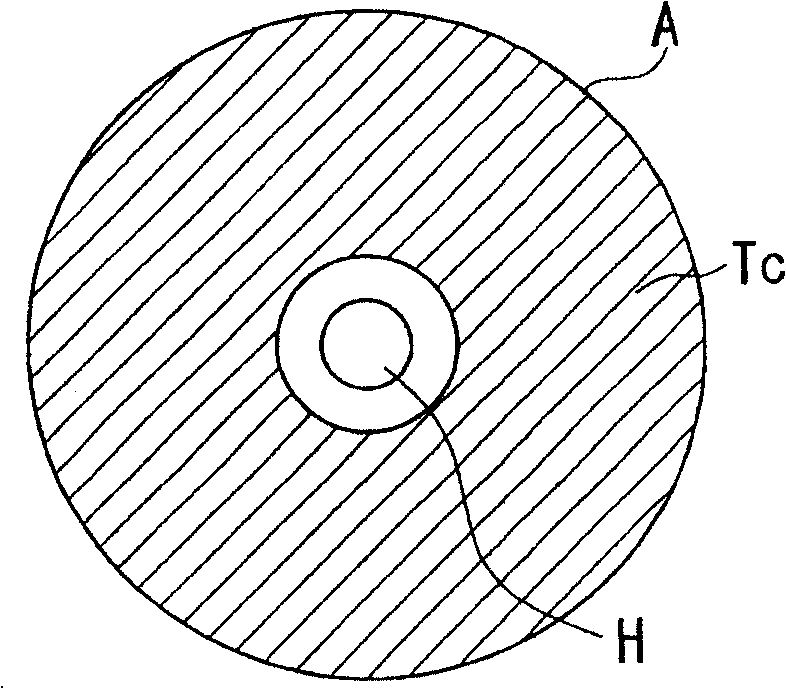

[0039] Figure 2 is used to illustrate Figure 1A A diagram of an example of forming an annular liquid film Ta of the adhesive shown. The adhesive supply nozzle 1 for supplying liquid adhesive to the optical disc substrate A is formed in a thin tube shape made of a common metal material, and performs a normal liquid supply operation. Adhesive supply nozzle 1 is connected to one terminal of AC power supply 2 and ground potential at the same time, and electrode mechanism 3 working as an electrode on the receiving table is connected to the other terminal of AC power supply 2 through switch 4 . Therefore, when the switch 4 is closed and the AC voltage from the AC power source 2 is applied between the adhesive supply nozzle 1 and the electrode mechanism 3, an AC electric field is formed therebetween. In the state where the AC electric field is formed, the receiving table is rotated at a constant speed for approximately one turn, and at the same time, a predetermined amount of liqui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com