End piece for a retrofit fluorescent lamp and retrofit fluorescent lamp

A technology for fluorescent lamps and terminals, which is applied to the safety device of the lighting device, the cooling/heating device of the lighting device, the components of the lighting device, etc., which can solve the problems of high assembly cost and electric shock, and achieve the effect of simple implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

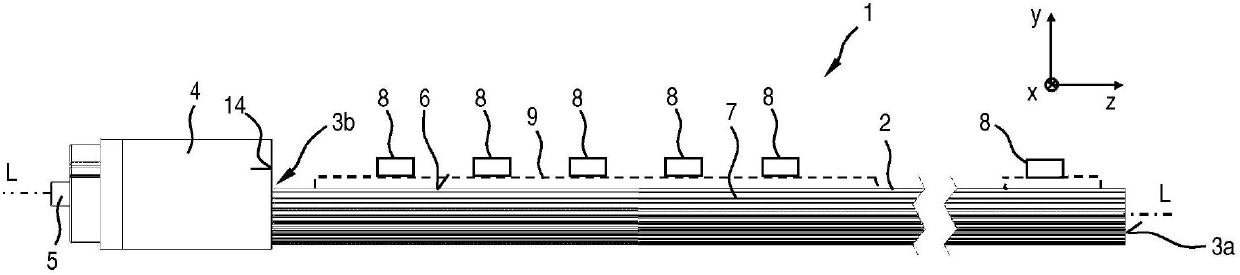

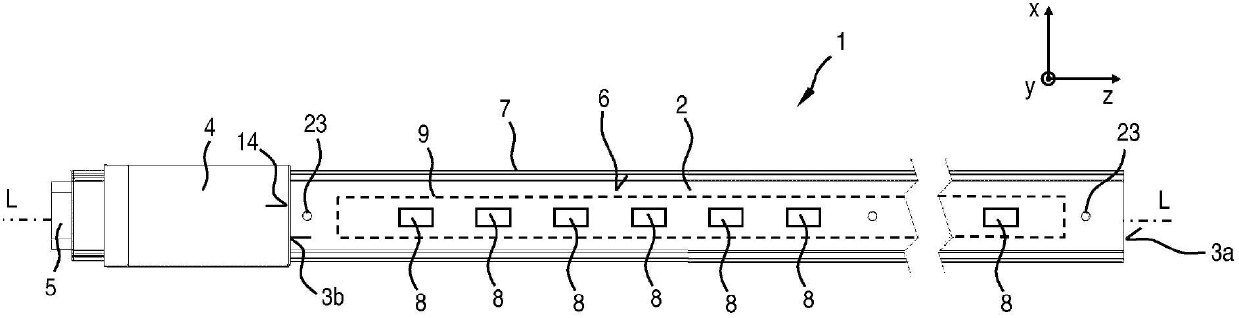

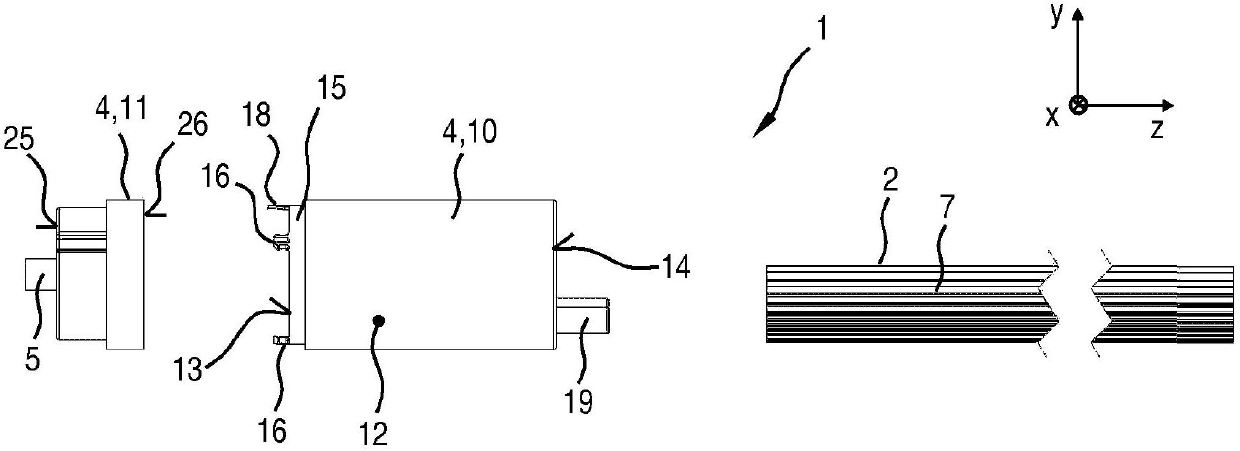

[0033] figure 1 shows a side view of part of an LED retrofit fluorescent lamp 1, and figure 2 A plan view of the LED retrofit fluorescent lamp 1 is shown. The LED retrofit fluorescent lamp 1 has a heat sink 2 as an intermediate part, which is covered on its two end sides 3a, 3b by end caps in each case. A terminal (not shown) provided for fastening at the end side 3a shown here on the right essentially serves to mechanically fasten the LED retrofit fluorescent lamp 1 in a conventional fluorescent lamp socket. Adjacent to the end side 3 b shown here on the left is a head 4 which is formed as a drive housing. In this case, the terminal 4 accommodates a driver (not shown), which converts the power supplied via the electrical connection 5 into a current or voltage suitable for the operation of the light-emitting diode 8 .

[0034] The end cap 4 has an at least approximately cylindrical outer contour, which is similar to that of a conventional fluorescent lamp. The cooling bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com