Manufacturing device of reinforcing steel bar cage of centrifugal force concrete pipe pile

A concrete pipe pile and manufacturing device technology, which is applied in the direction of manufacturing tools, resistance welding equipment, welding equipment, etc., can solve problems such as low production efficiency and shaft tendon bending, and achieve the goal of improving work efficiency, improving production efficiency, and saving installation time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the drawings.

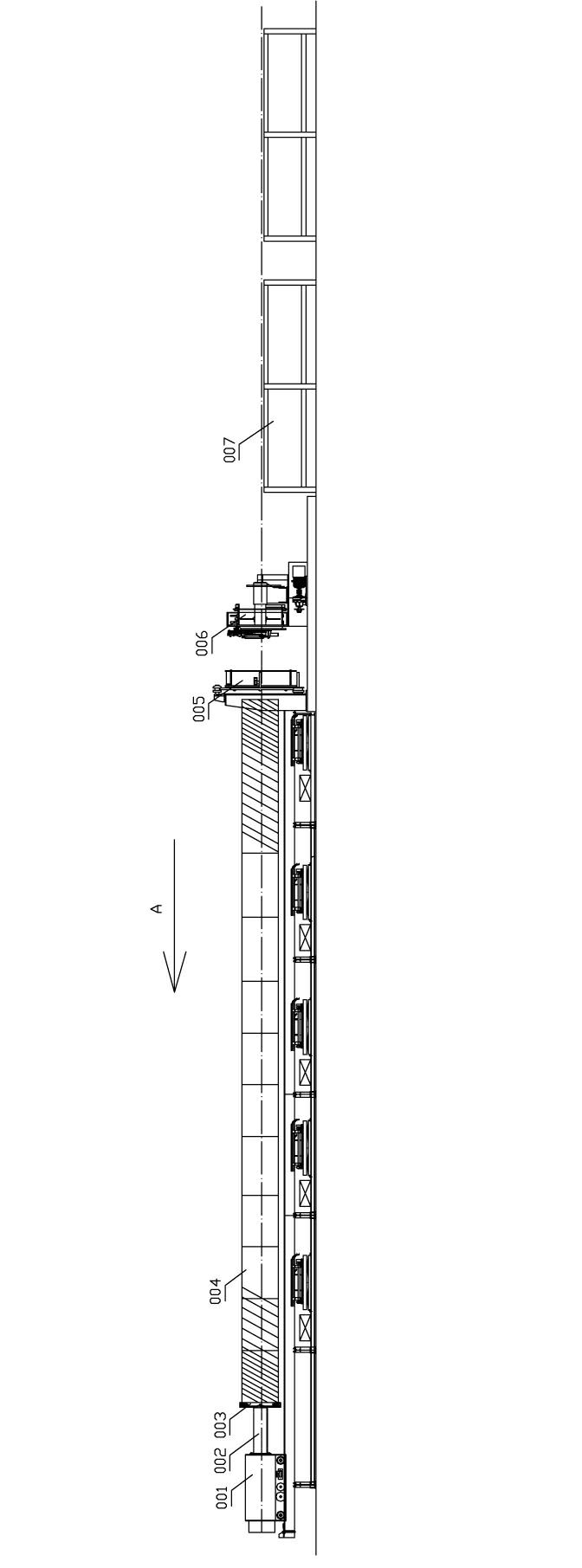

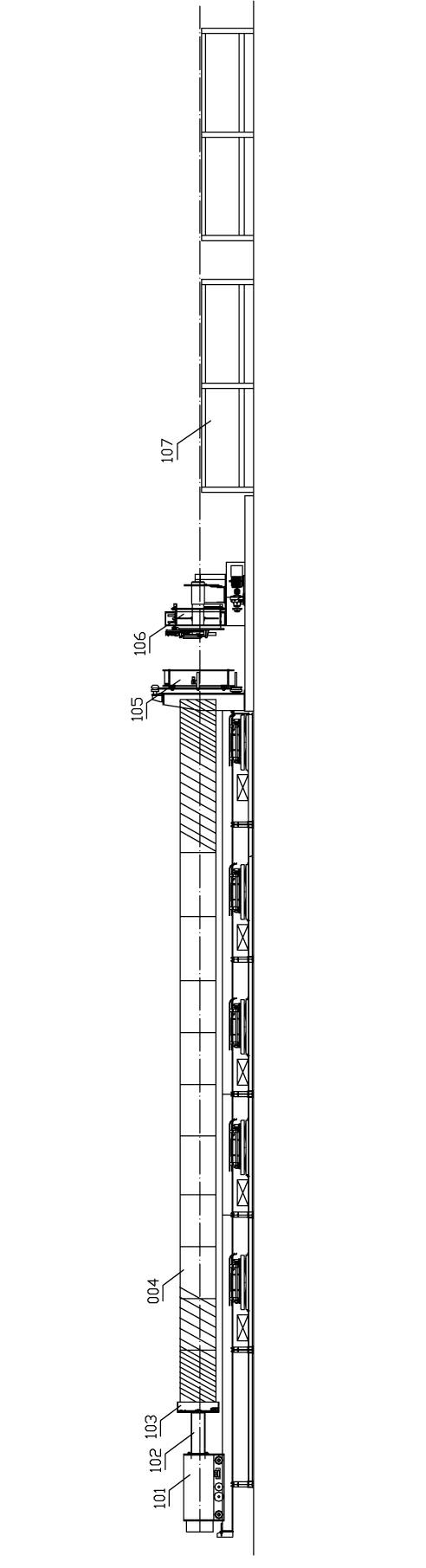

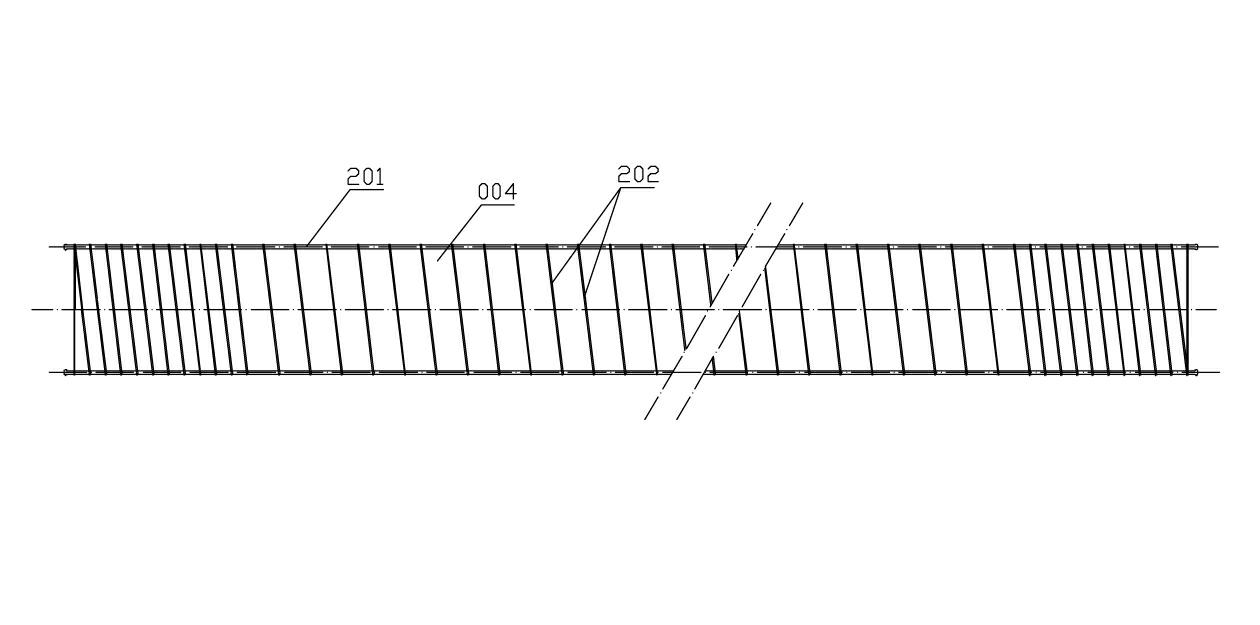

[0029] Attached figure 2 And Figure 7 , A manufacturing device for the reinforcement cage of centrifugal concrete pipe piles, which includes a traction device for pulling the shaft reinforcement 201 of the reinforcement cage and a welding machine for welding the spiral reinforcement 202 to the periphery of the shaft reinforcement of the reinforcement cage. The traction device is installed In front of the welding machine, an end plate clamping platform 103 for installing the end plate of the steel cage is provided on the traction device.

[0030] Further binding Figure 8 To attach Picture 11 , The traction device is a traction trolley 101, the welding machine is a seam welding machine 106, the traction trolley 101 is provided with a traction arm 102, and the end of the traction arm 102 is installed with an end plate clamping platform 103, the The end plate chuck 103 includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com