Ratchet wrench main body and manufacturing method thereof

A ratchet wrench and body technology, which is applied in the ratchet wrench field, can solve the problems of difficulty, difficult to move the top stopper, difficult drilling, etc., and achieve the effect of uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

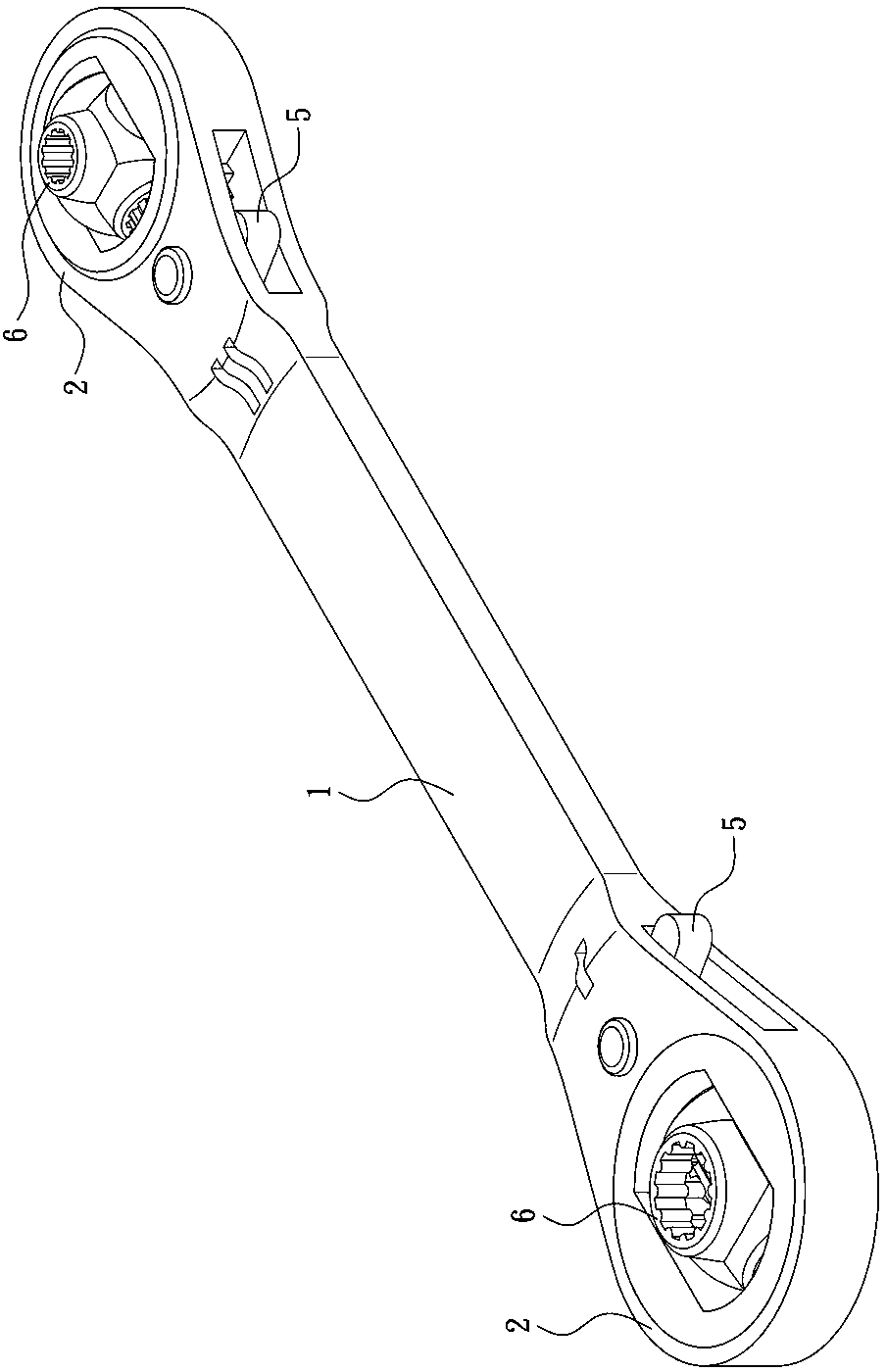

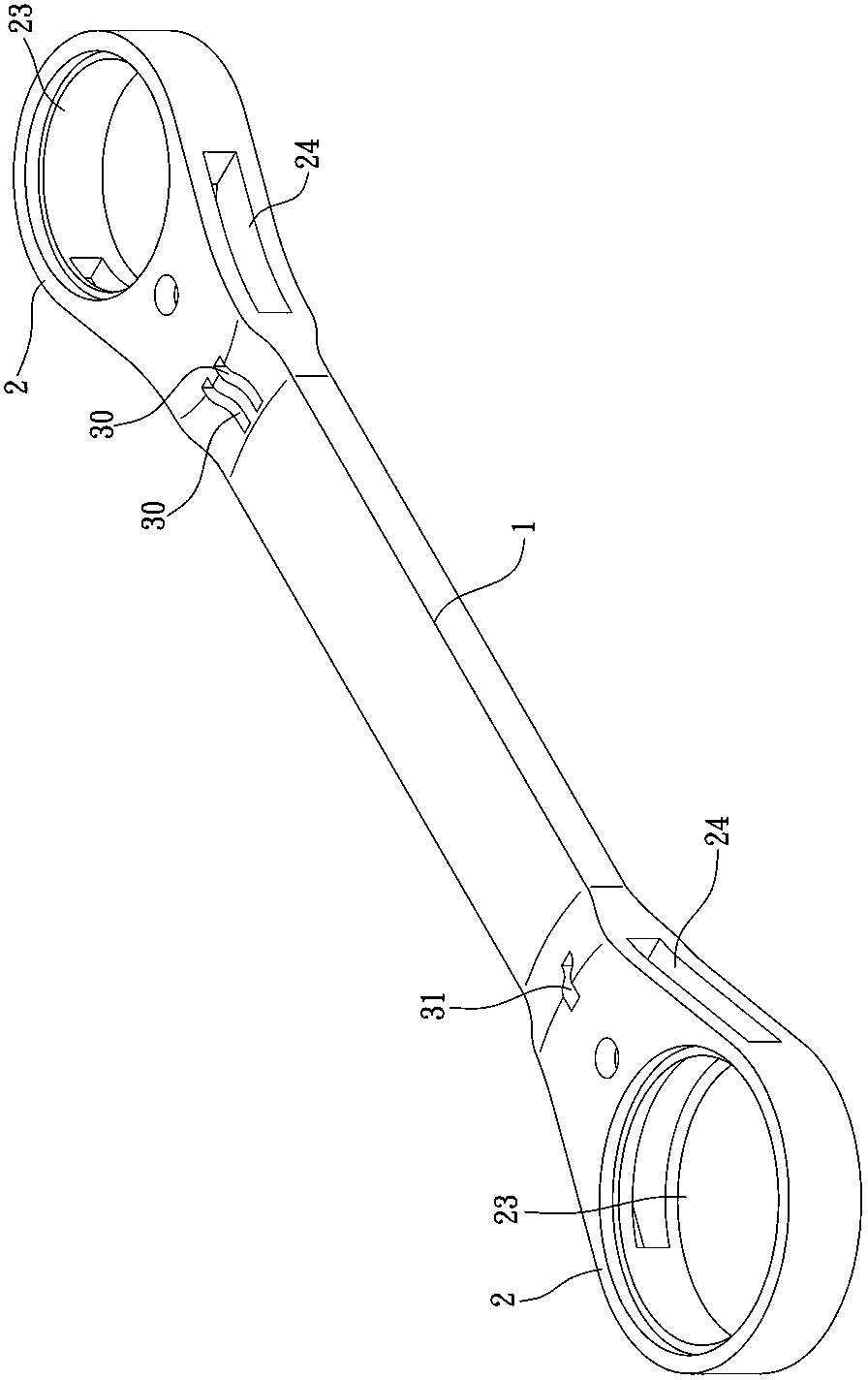

[0033] see Figure 1 to Figure 6 Shown in the figure is the structure of Embodiment 1 selected by the present invention, which is for illustration only, and is not limited by this structure in the patent application.

[0034] The present invention provides a structure of a ratchet wrench body. The structure of the ratchet wrench body can be applied to a ratchet wrench of a one-way drive type, and can also be applied to a ratchet wrench of a two-way switching drive type. Drive type ratchet wrench as an example, that is, figure 1 As shown, the ratchet wrench includes a handle 1, which has a head 2 at both ends of the handle 1, and the ratchet wrench formed by the handle 1 and the two heads 2 is integrally formed and in a straight shape. In addition, the two heads 2 of this embodiment are respectively provided with a sleeve 6 driven by a two-way pulling block 5 .

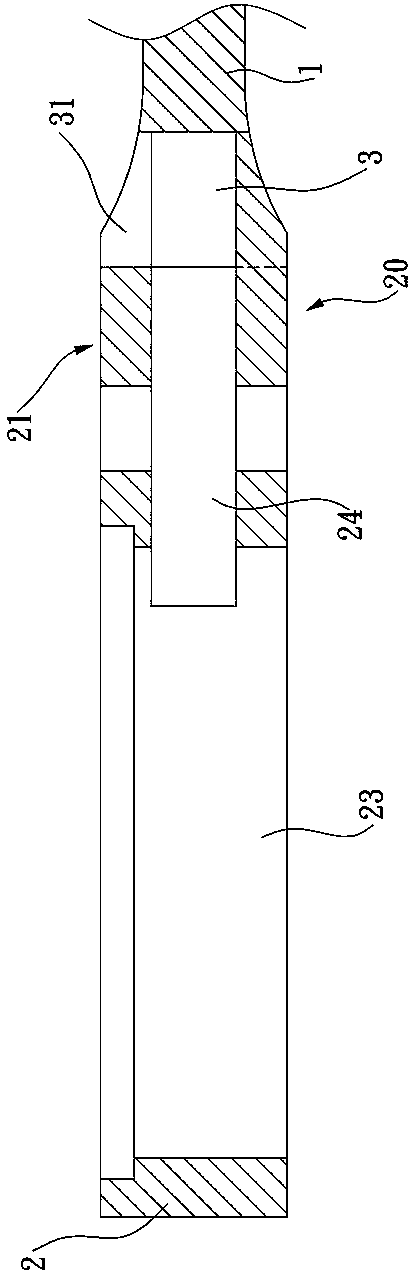

[0035] Such as Figure 2~3 As shown, the head 2 is divided into a first surface 20 and a second surface 21 on tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com