Deck ladder for follow-up horizontal ship

A deck ladder and horizontal technology, which is applied to ship accessories, ships, cargo handling equipment, etc., can solve the problem that the structure cannot meet the requirements of adaptive displacement and swing of the receiving ship, and achieve humanized boarding operation functions and construction operations Convenience and the effect of improving the ergonomics environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

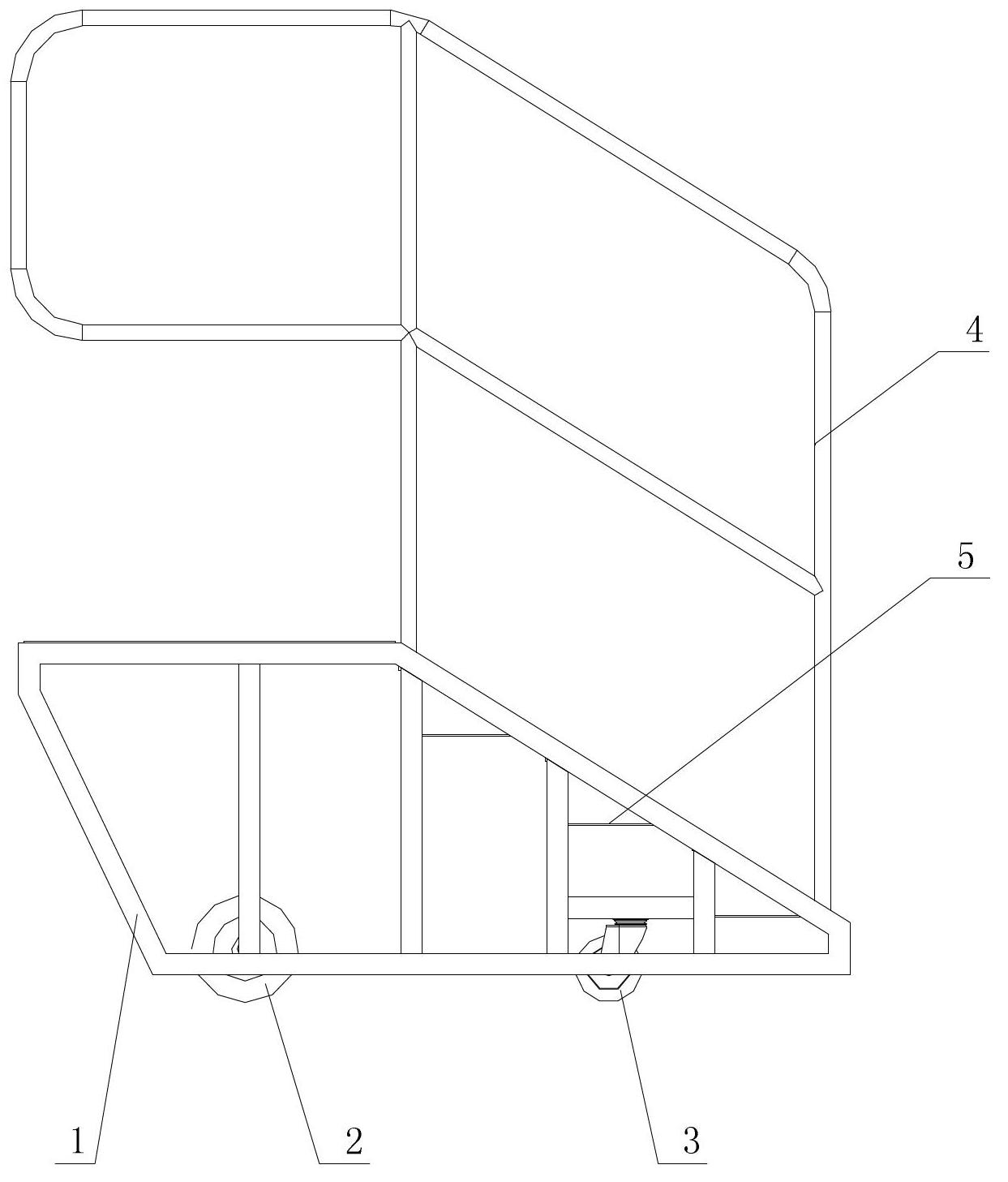

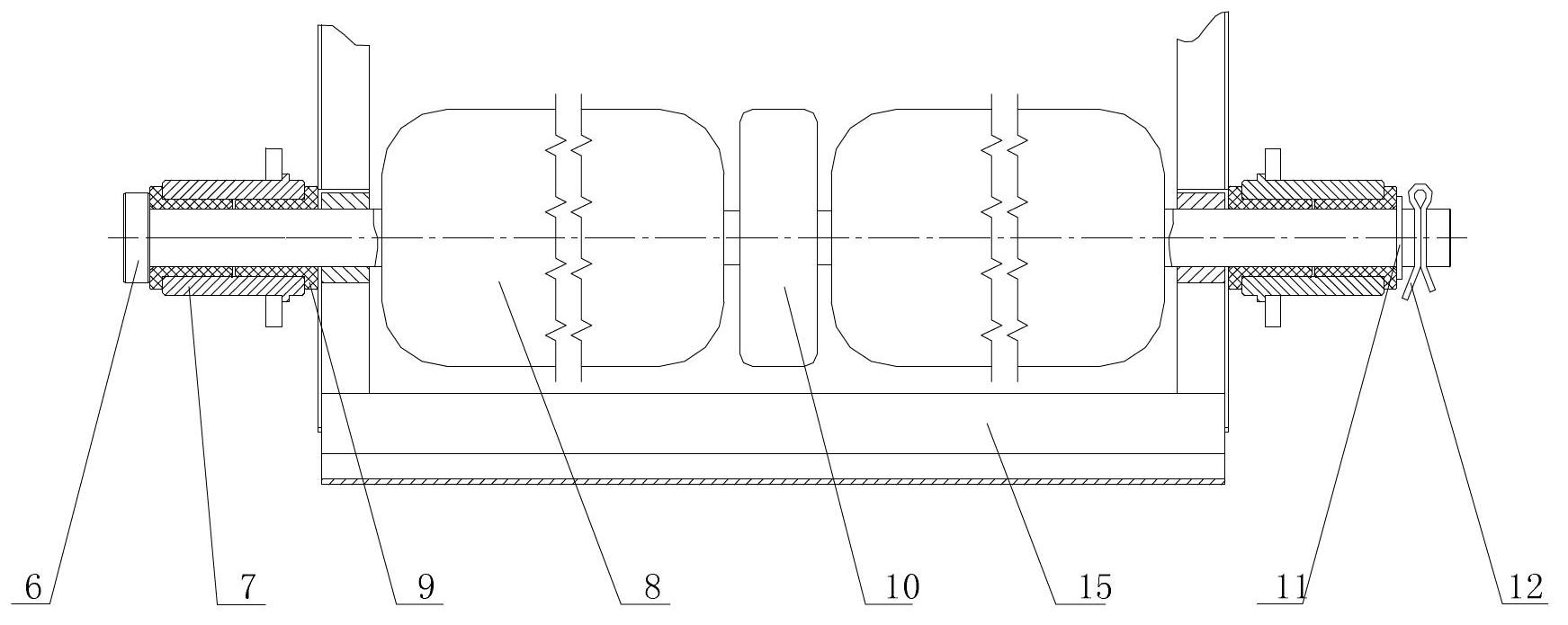

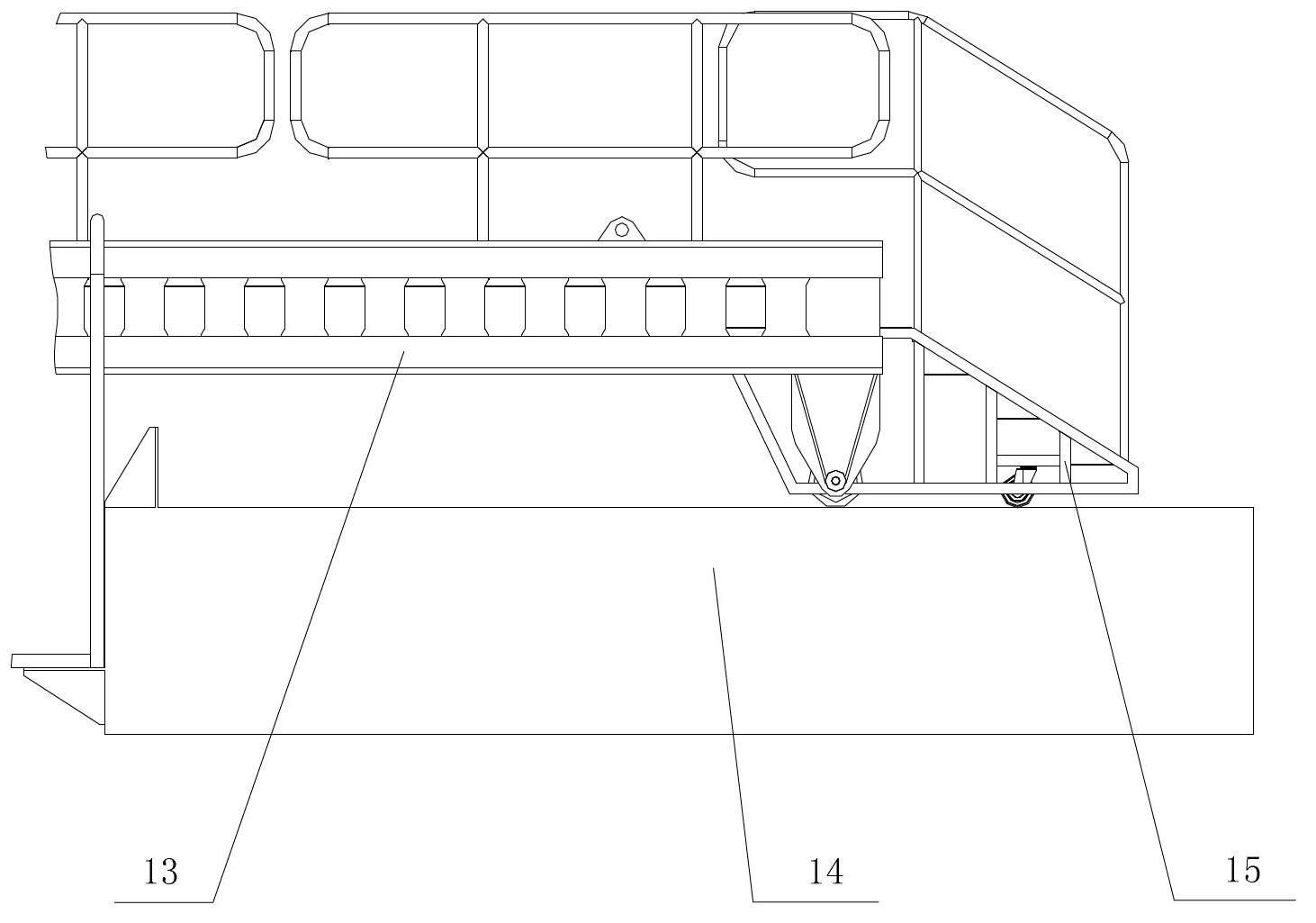

[0017] The basic structure of the follow-up horizontal marine deck ladder of the present embodiment is as attached figure 1 As shown, it mainly includes a deck ladder frame 1, a safety guardrail 4 and a roller part arranged at the bottom of the deck ladder frame. The deck ladder frame 1 has a group of upward boarding steps 5, and the safety guardrails are installed on both sides of the boarding steps. on the deck ladder frame 1, and the safety guardrail 4 is a detachable structure, and a forward structure is provided at the front end of the safety guardrail; the roller parts at the bottom of the deck ladder frame include a rubber roller assembly 2 and a universal wheel assembly. The wheel assembly consists of two universal wheels 3, which are installed on the caster support of the deck ladder frame; the rubber roller assembly 2 is installed at the bottom of the deck ladder frame 1 near the side of the ramp At the bottom of the deck ladder frame on the side away from the gangwa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com