Bearing lubricating waste oil collection system of wind driven generator

A wind turbine, bearing lubrication technology, applied in the direction of engine lubrication, shaft and bearing, bearing components, etc., can solve the problems of large influence of external factors, inability to guarantee regular collection, and increase labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

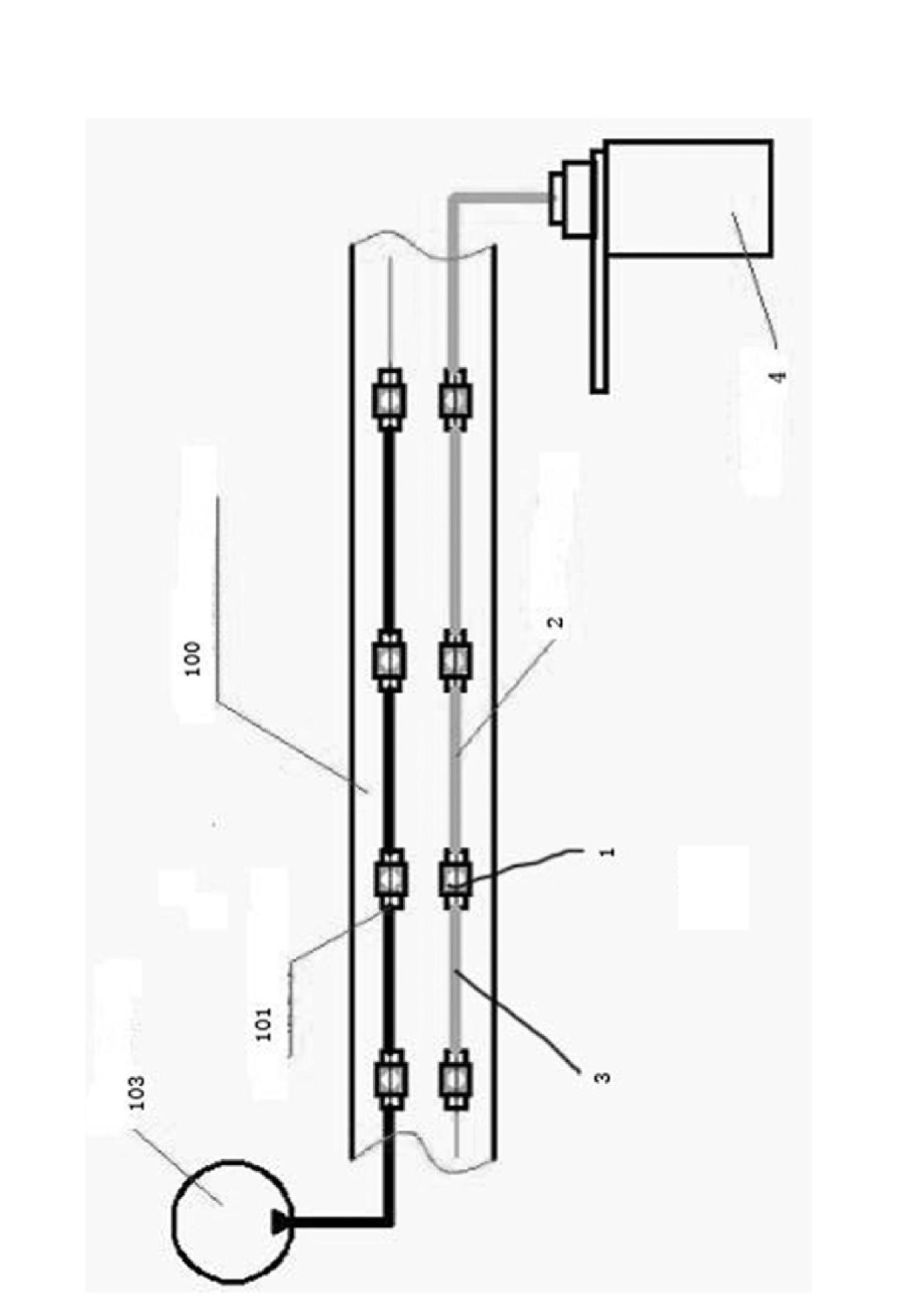

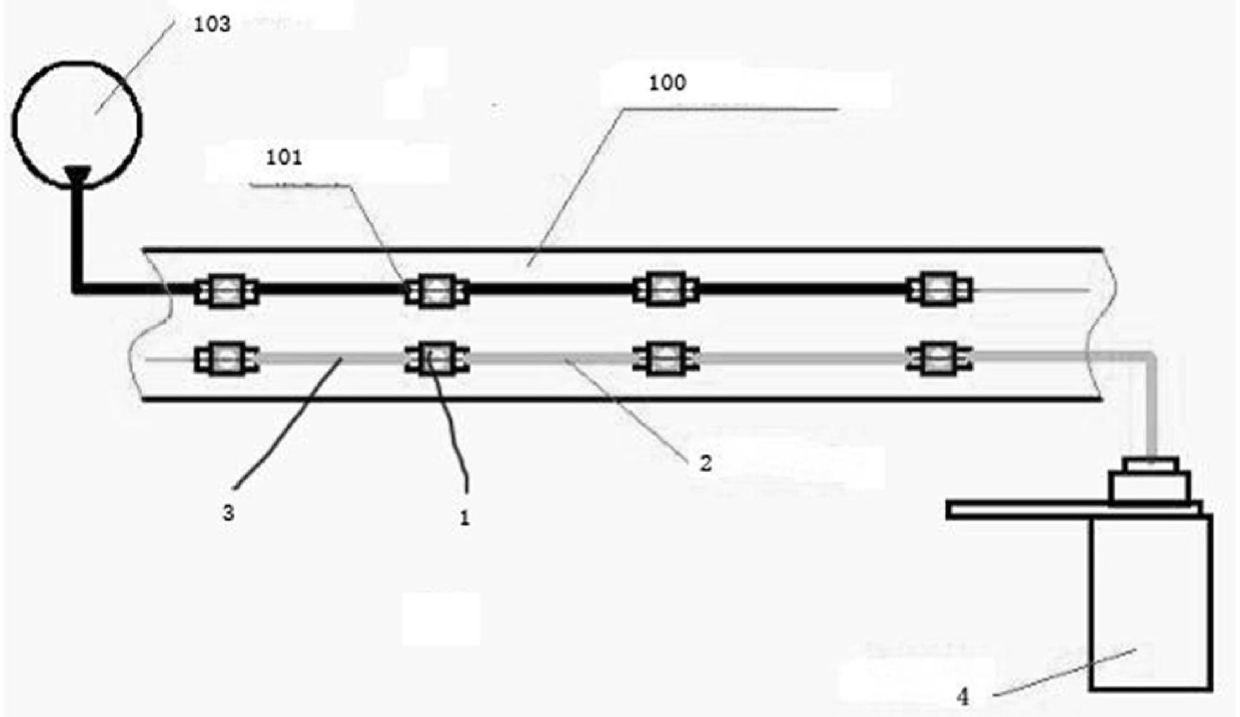

[0010] The bearing lubricating waste oil collection system of the wind power generator, the bearing 100 of the wind power generator is provided with a plurality of bearing lubricating waste oil outlets 1, and the plurality of bearing lubricating waste oil outlets 1 are connected in series Pipe 2, a plurality of bearing lubricating waste oil outlet holes 1 and connecting pipe 2 form a bearing lubricating waste oil collection pipeline 3, and one end of the bearing lubricating waste oil collecting pipeline 3 is connected with a bearing lubricating waste oil collecting bottle 4. The bearing lubricating waste oil collecting bottle 4 is arranged at the lower end of the bearing lubricating waste oil collecting pipeline 3, and the present invention can also be provided with an electronic device controlled by a circuit between the bearing lubricating waste oil collecting pipeline 3 and the bearing lubricating waste oil collecting bottle 4. Valve, use the circuit to control the on and of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com