A defrosting method for heat pump

A technology for heat pumps and evaporators, applied in the defrosting field of heat pumps, to eliminate individual differences in heat pumps, reduce time and energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

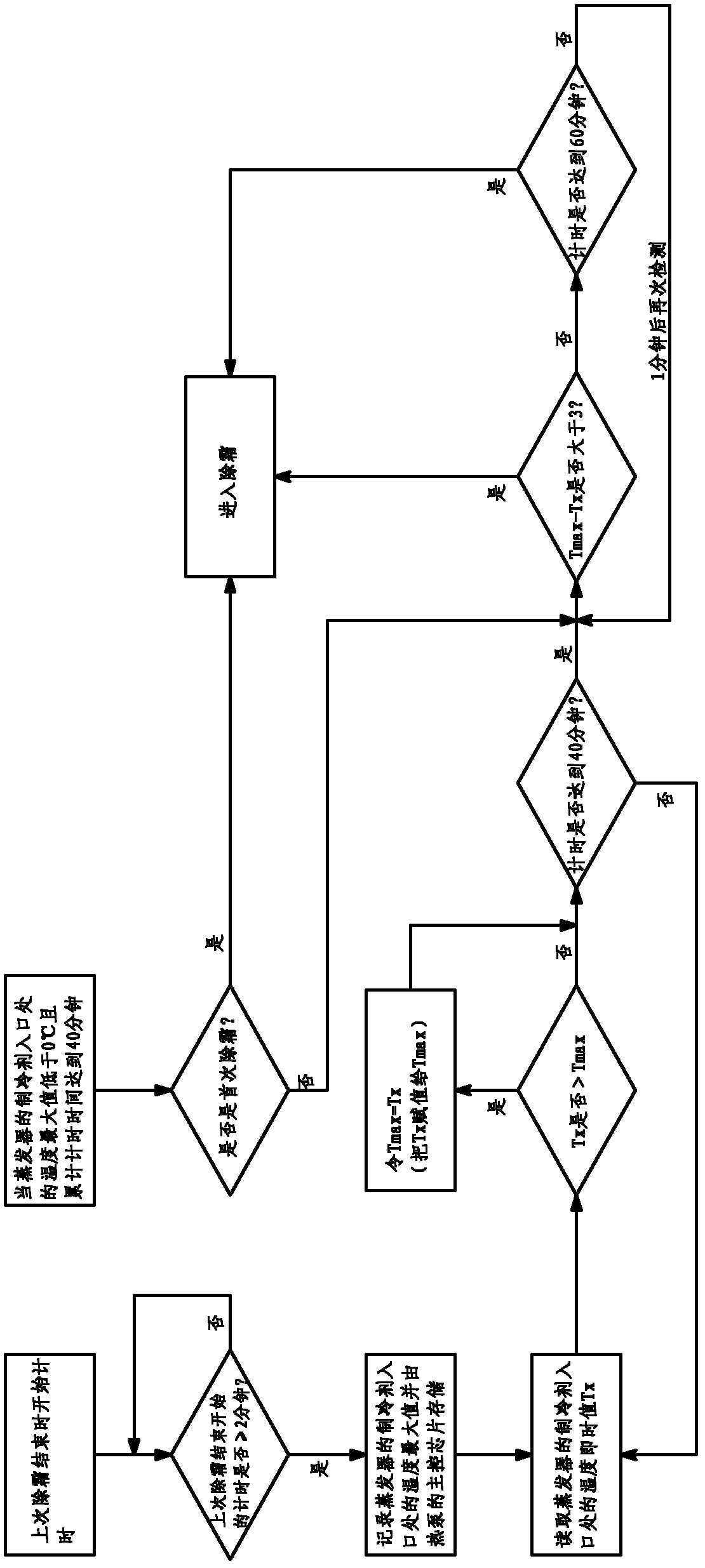

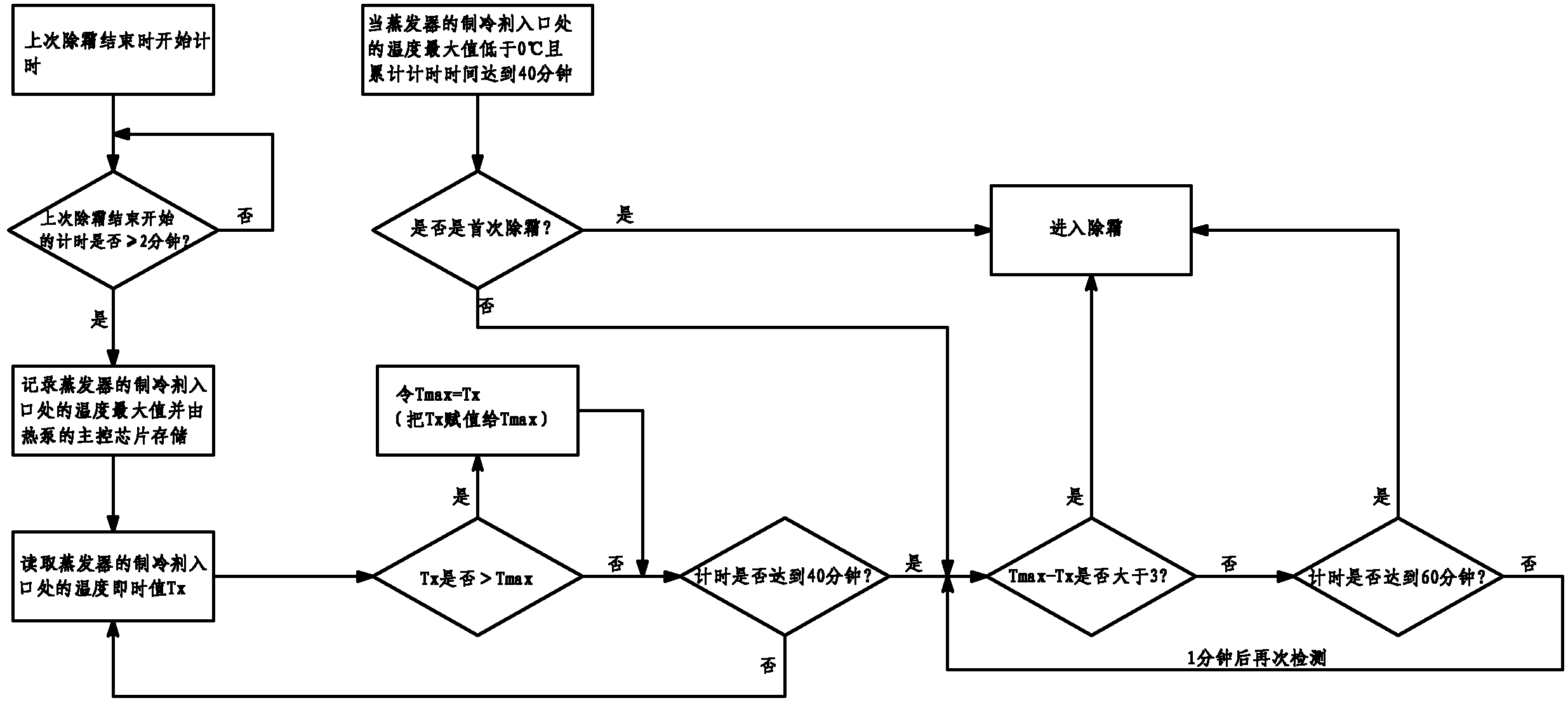

[0029] see figure 1 , the defrosting method of the heat pump, comprising the following steps:

[0030] In step one, more than one temperature sensor for detecting the temperature of the evaporator is arranged on the evaporator of the heat pump. In this embodiment, a temperature sensor can be set at the refrigerant inlet of the evaporator; of course, it is also possible to set a temperature sensor at other parts of the evaporator.

[0031] Step 2, the first defrosting during the operation of the heat pump adopts a timing defrosting method, and defrosting is performed after detecting that the temperature of the evaporator is lower than 0°C and lasts for 40 minutes.

[0032] The first defrosting refers to the first defrosting after the compressor of the heat pump is turned on or turned on again after being shut down.

[0033] Step 3, determine the maxim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com