Device and method for detection, rejection and docking of rigid electric ignition charge

A technology of a igniter head and a docking device, which is applied to fuzes, weapon accessories, offensive equipment, etc., can solve the problem that the resistance of the rigid electric igniter head cannot be detected online, and the resistance of the electric igniter element is unstable and lacks integrity. Connection discontinuity and other problems, to achieve the effects of good ignition synchronization, improved seismic resistance, and stable resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

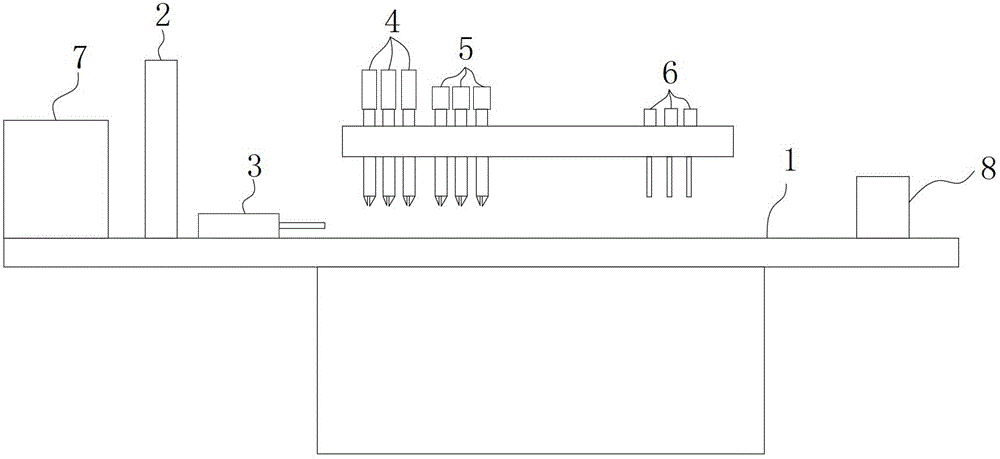

[0034] Please refer to figure 2 , image 3 , the present invention provides a detection, removal and docking device for rigid electric ignition powder, which includes: workbench 1, crimping machine 2, stepping mechanism 3, 3 sets of rigid electric ignition powder resistance automatic detection machine 4, 3 A rejecting machine 5, three hot-press welding machines 6, a PLC (not shown), a computer 7 and an ejection device 8.

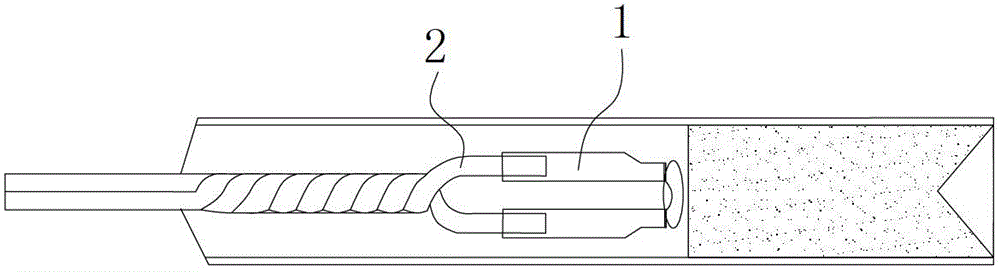

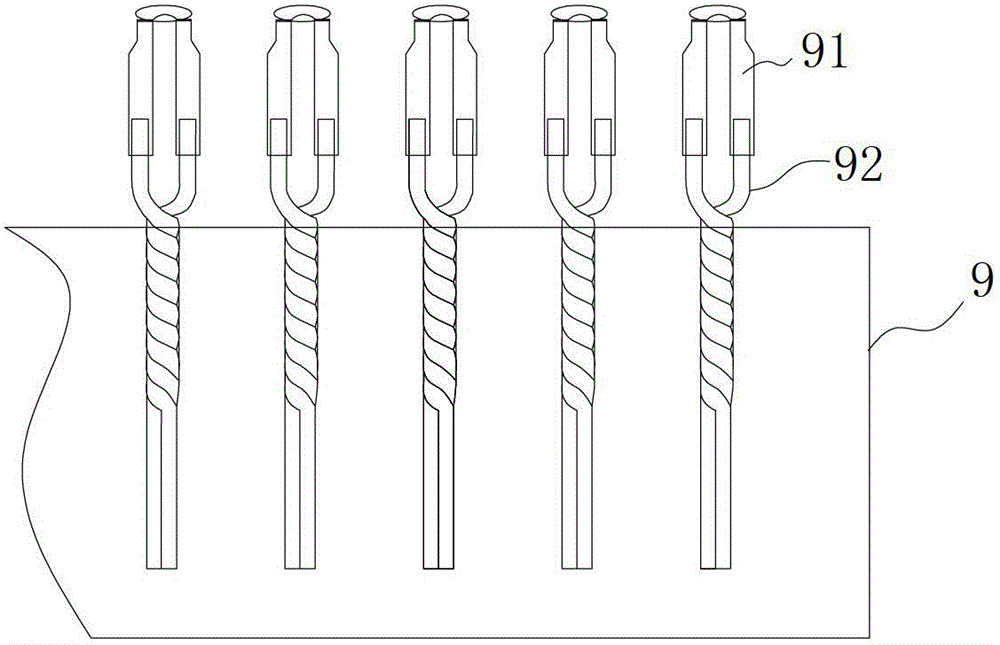

[0035] The crimping machine 2 is arranged on the workbench 1 and is used for crimping the rigid electric ignition charge head 91 on the leg wire 92 .

[0036] The stepping mechanism 3 is a mold pushing cylinder, which is used to push the rigid electric ignition powder head module 9 to move.

[0037] The 3 sets of automatic detection machines 4 for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com