Sensor

A sensor and core technology, applied in the field of sensors, can solve problems such as limiting the range of use of sensors, affecting the deformation of silicon chips, and large measurement errors, and achieves the effects of large-scale production, reliability and high precision, and reduced product costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

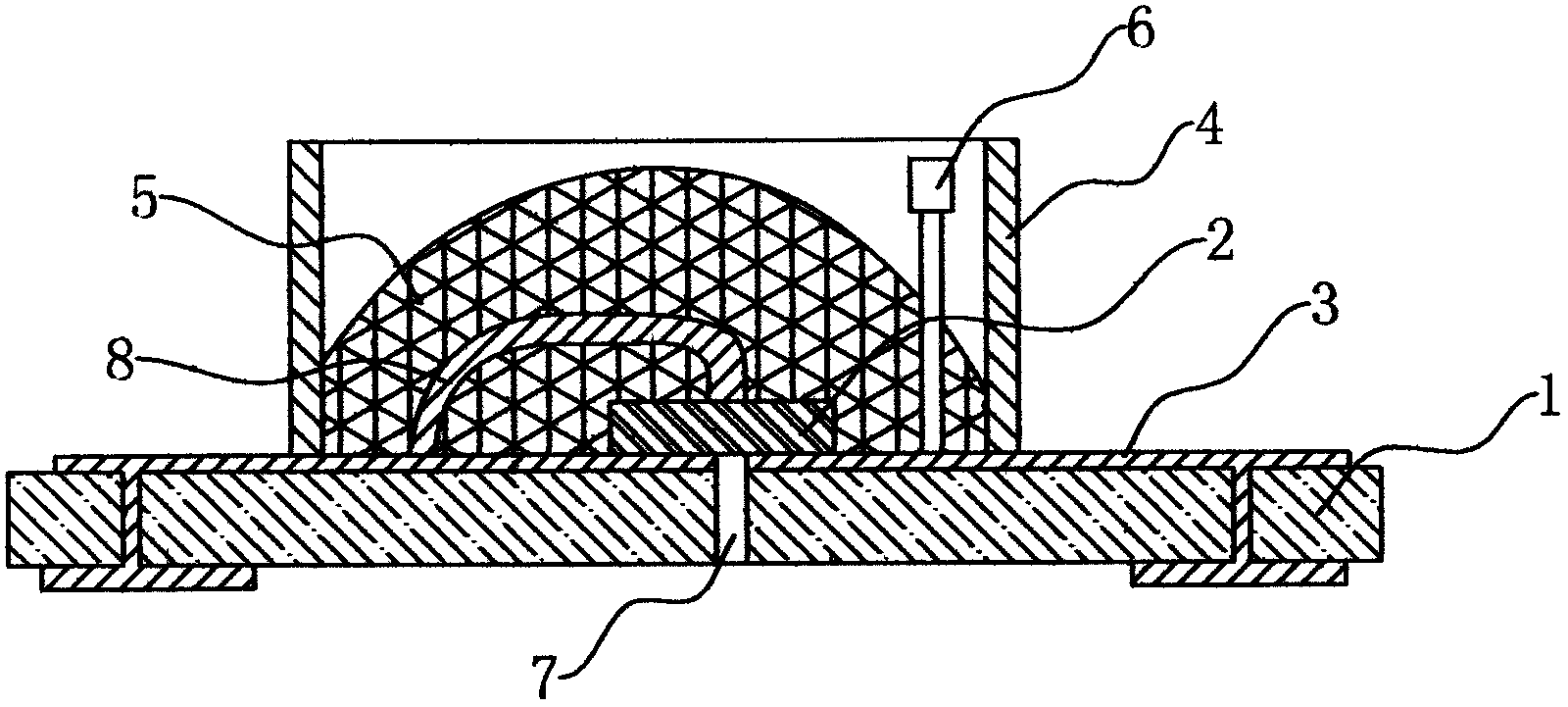

[0013] refer to figure 1 , a sensor of the present invention, comprising a circuit board 1, a pressure core 2 is bound on the circuit board 1 through a conductive wire 8, and a conductor 3 is connected to the outside of the pressure core 2, and the circuit board 1 is based on ceramics ceramic circuit board. This sensor uses a ceramic circuit board with ceramics as the substrate. Since the thermal expansion coefficient of the ceramic is close to that of the pressure core, it avoids the difference in thermal expansion coefficient between the two, and the deformation of the circuit board will affect the deformation of the pressure core. Sensors in different temperature ranges have reliable high precision. At the same time, the ceramic circuit board with ceramics as the substrate is a conventional circuit board with low cost, which is conducive to large-scale production and can effectively reduce product costs. Circuit boards based on ceramics have excellent mechanical strength,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com