Dome hyperboloid forming equipment

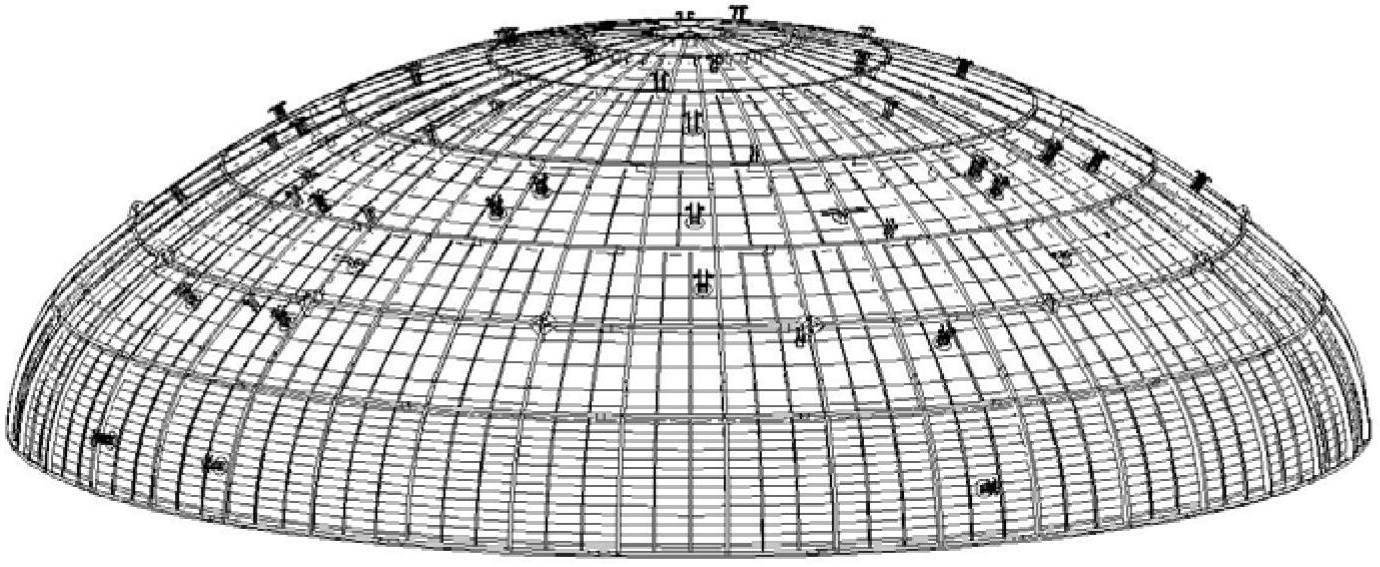

A forming equipment and hyperboloid technology are applied in the field of dome hyperboloid forming equipment and special equipment for nuclear power plant containment steel lining dome hyperboloid forming, which can solve the problems of low production efficiency, large amount of prefabrication engineering, complicated design of pressed tire membrane, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

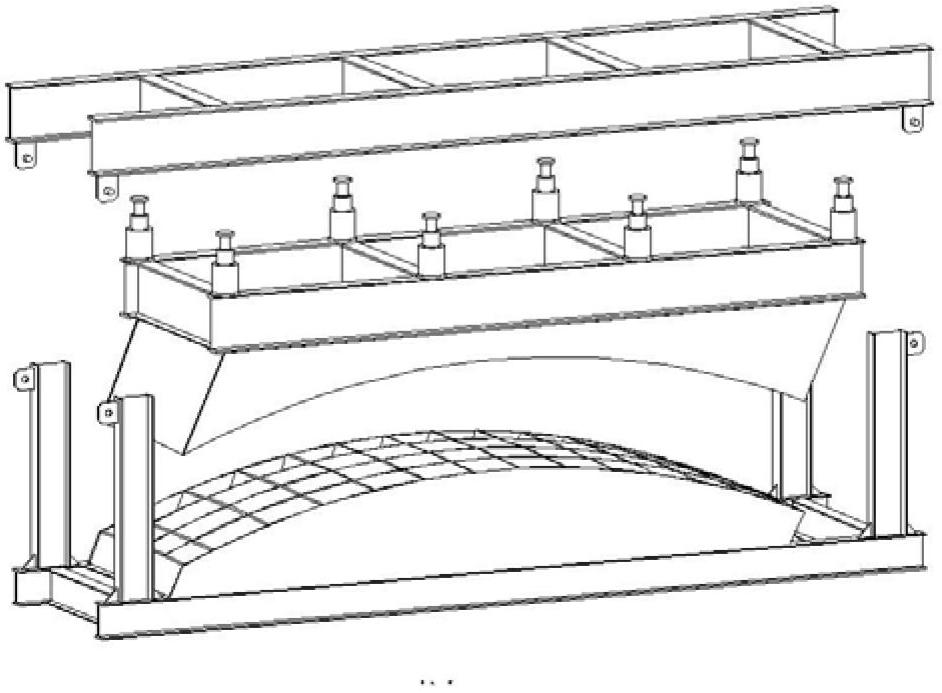

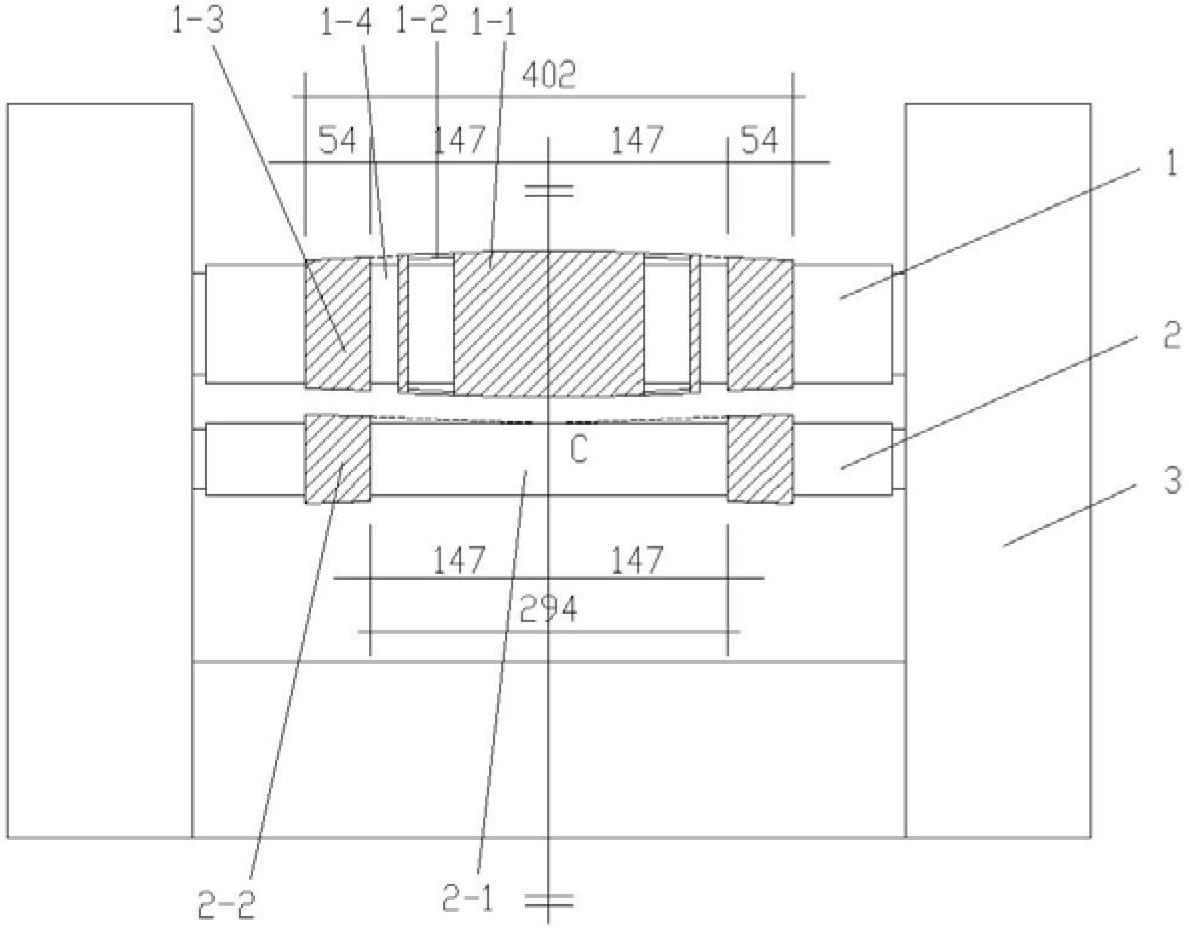

[0017] The dome hyperboloid forming equipment of the present embodiment is as image 3 and Figure 4 As shown, an upper roller 1 and a pair of lower rollers 2 are supported on a frame 3 and are parallel to each other. The middle part of the upper roller 1 is fixedly equipped with a middle punch 1-1, and the two ends of the middle punch 1-1 are fixed with the sleeve mold 1-2 forming a continuous busbar, so that the length is about 60% of the width of the dome unit plate to be formed of the convex segment. The two sides of the central convex section correspond to the positions of the width of the dome unit plate to be formed, and the end convex rings of about 13% of the width of the dome unit plate to be formed are respectively fitted to form the end convex section 1-3, and the intervals 1-4 are formed between the middle part and the two sides. The busbars of the end convex section 1-3 and the extension line of the busbar of the middle convex section form a continuous arc. Acc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com