Double air flow structure partial dry underwater robot welding miniature drainage cover

A technology of underwater robot and local dry method, which is applied in the direction of gas flame welding equipment, welding equipment, metal processing equipment, etc., and can solve the problems that affect the precise positioning of the welding robot's underwater torch, large engineering application limitations, and poor process adaptability and other problems, to achieve the effect of strengthening drainage protection, enhancing flexibility, and improving the effect of welding seam protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

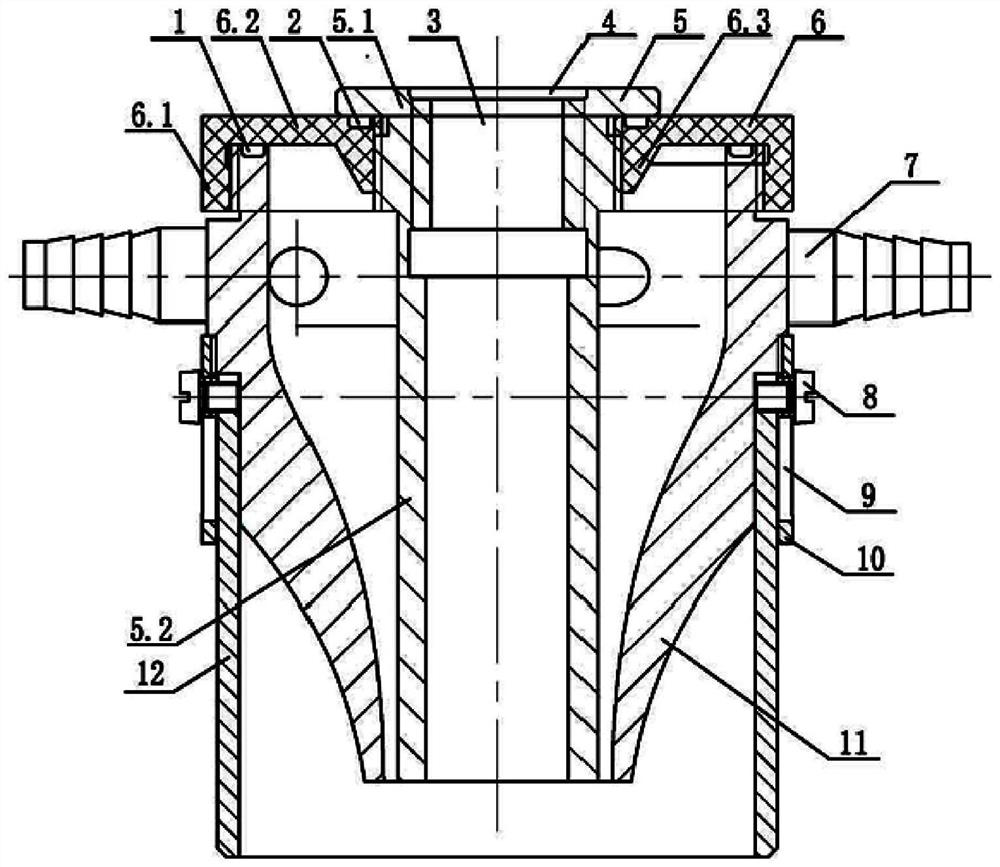

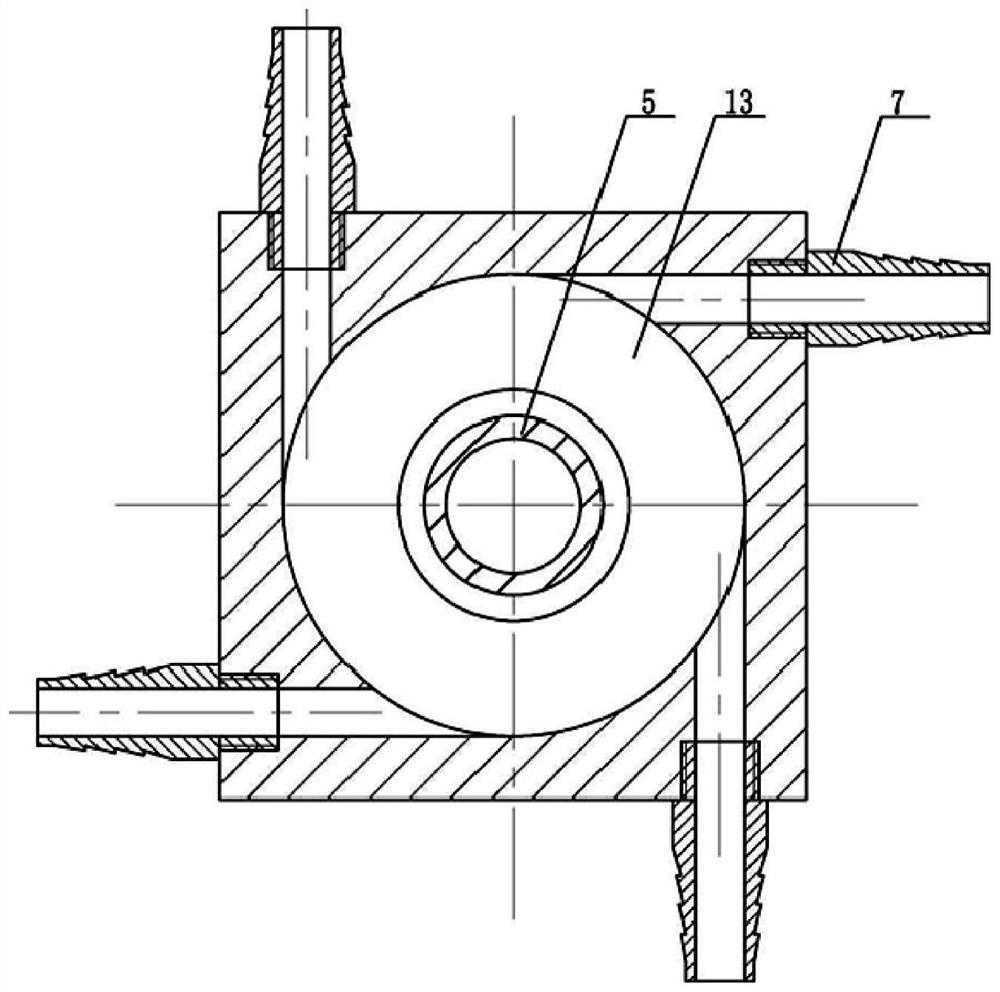

[0028] Such as Figure 1 ~ Figure 3 As shown, the partial dry-process underwater robot welding micro-drainage cover of this embodiment includes an inner air cover 5, an outer air cover 11 and a water retaining jacket 12 arranged in sequence from the inside to the outside. A welding torch installation hole 3 for setting a welding torch is formed inside the inner gas cover 5; the wall of the welding torch installation hole 3 is provided with an internal thread for installing a welding torch. A convergent shrinking nozzle cavity 13 is formed between the outer air cover 11 and the inner air cover 5; the top cover of the shrinking nozzle cavity 13 is provided with a sealing cover 6; the outer air cover 11 is connected with four air intake pipes 7; The lumens of each intake pipe 7 communicate with the contracting nozzle cavity 13 to realize the input of compressed gas. The water blocking jacket 12 is made of flexible high temperature resistant composite material. The water retaini...

Embodiment 2

[0041] In this embodiment, the double airflow structure local dry process underwater robot welding miniature drainage cover, such as Figure 4 As shown, it is applied to underwater fillet welding. During underwater fillet welding, the workpieces are perpendicular to each other, and the water retaining sleeve 12 is cut into a V shape according to actual requirements to adapt to actual engineering applications. The rest of the structure of this embodiment is the same as that of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com