Mechanical arm climbing equipment

A technology for manipulators and pole climbers, which is applied to manipulators, manufacturing tools, etc., can solve the problems of increasing the inconsistency of the crawling action and the clamping action of the climbing claw, and achieve the effect of coordination of the climbing pole movements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

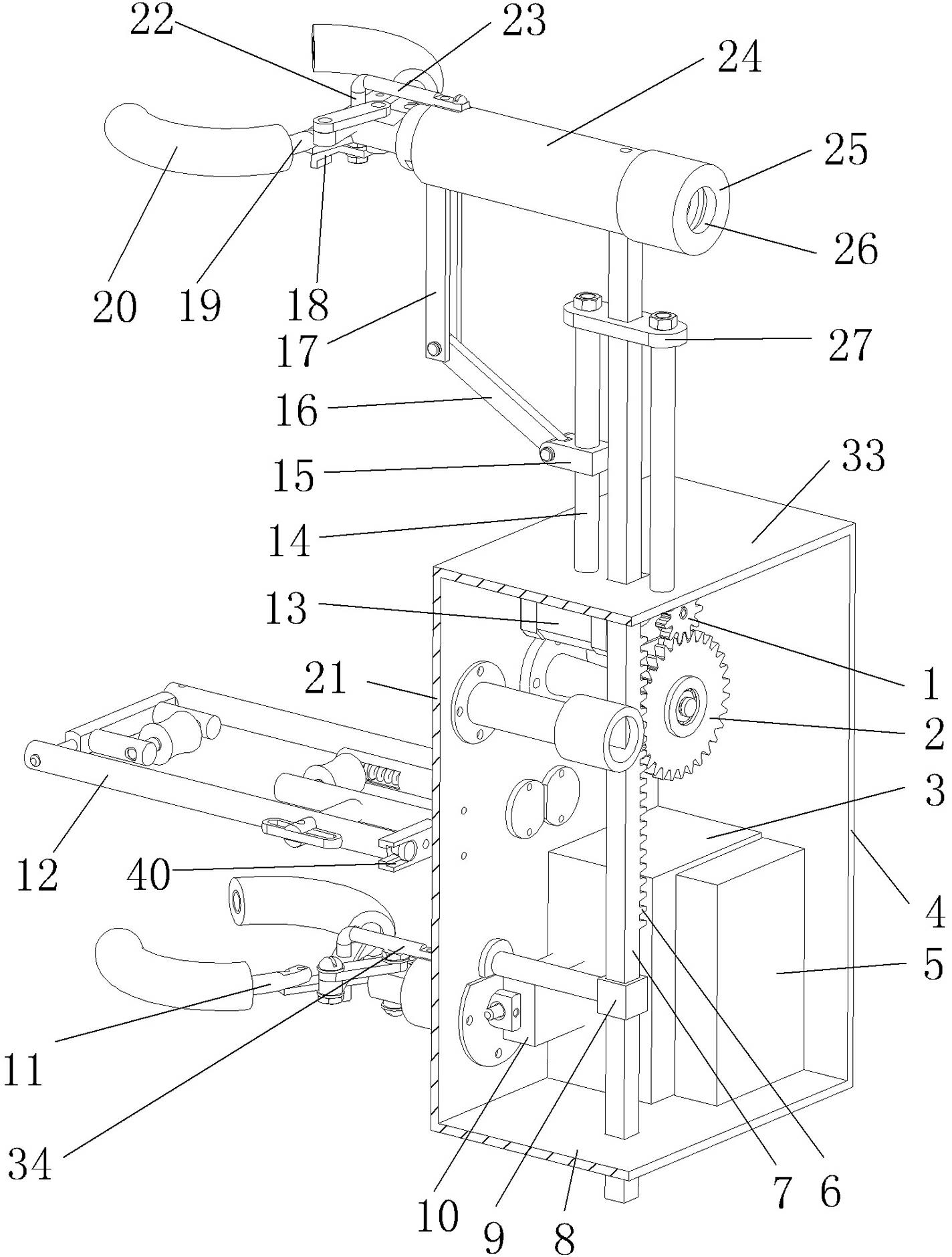

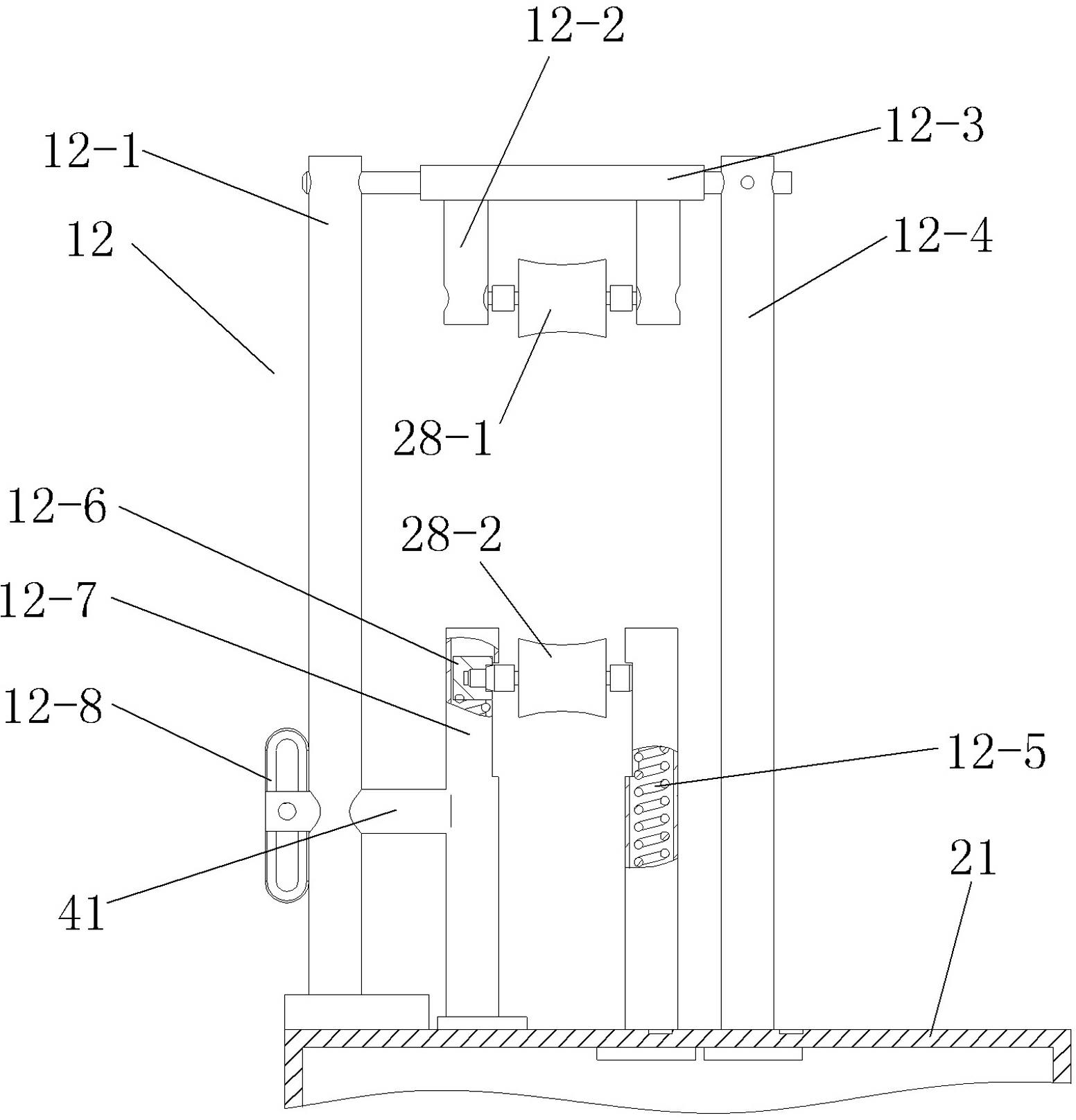

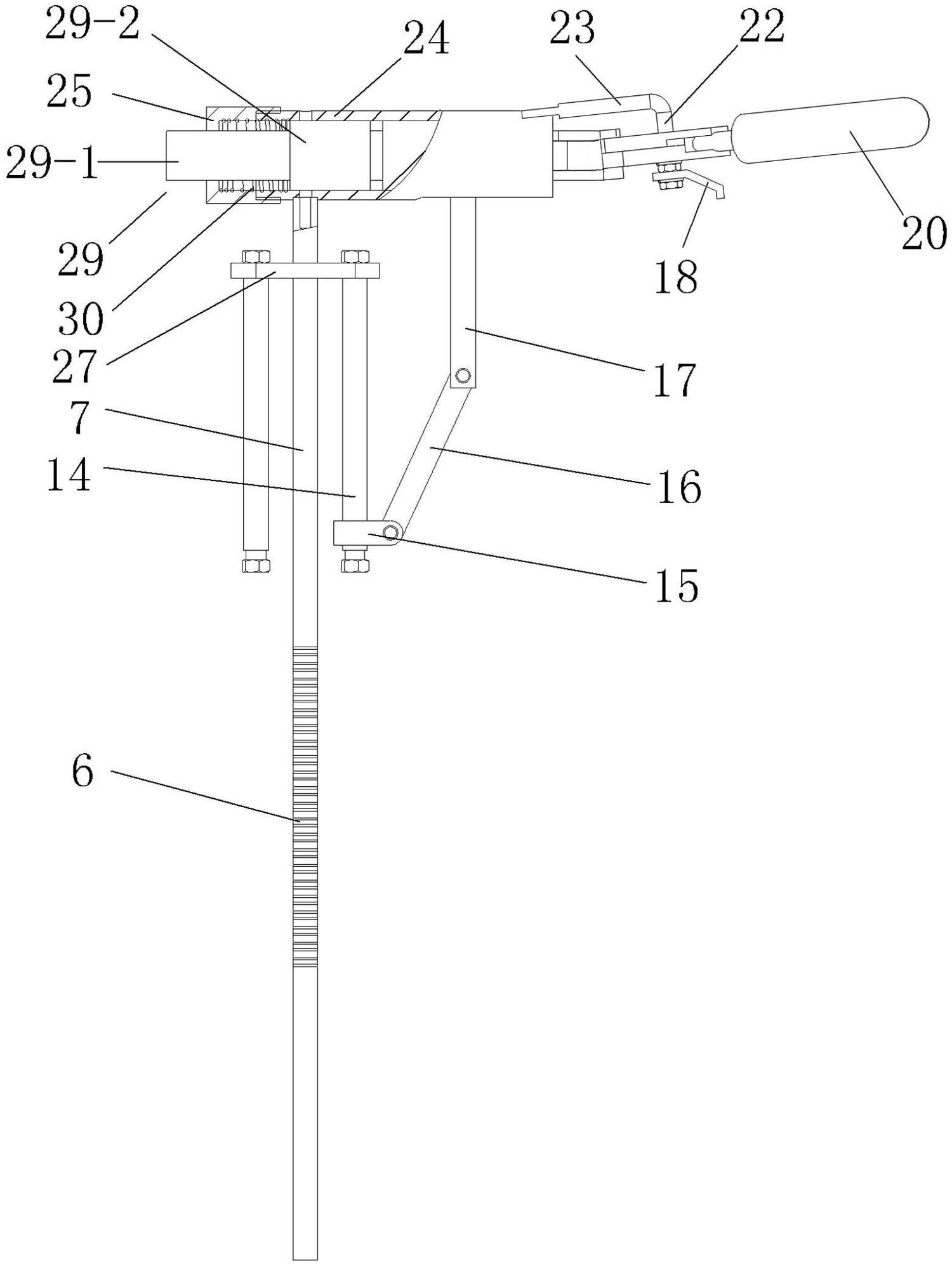

[0022] Embodiment 1 of a kind of manipulator pole climber is as Figure 1~4As shown: the bracket 4 including the box structure, the bracket is surrounded by a box cover, and the front side of the bracket 4 is provided with an upper climbing claw 19 and a lower climbing claw 11 for clamping and disengaging with the corresponding climbing pole. The climbing claw 19 includes a pair of upper opening and closing claws and an upper power input end that controls the opening and closing of the pair of upper opening and closing claws after being pushed and pulled; Then control the lower power input end of the opening and closing action of the pair of lower opening and closing claws. A lifting mechanism that cooperates with the upper and lower climbing claws to make the manipulator climb up the corresponding climbing rods is also provided between the upper and lower climbing claws. The support 4 guides and slides along the up and down direction and is equipped with a lifting rod 7 that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com