Double-ferrule type pipe joint

A ferrule type and pipe joint technology, which is applied in the direction of pipe/pipe joint/pipe fitting, sealing surface connection, passing components, etc., can solve the problems of loose ferrule, inability to withstand high pressure, unsuitable connection and use of test instrument pipe joints, etc. , to achieve increased reliability, reliable sealing performance, and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

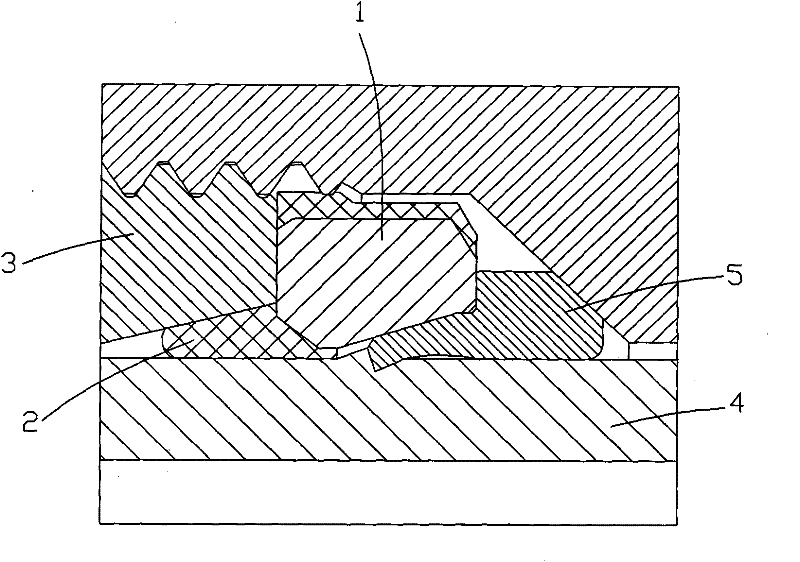

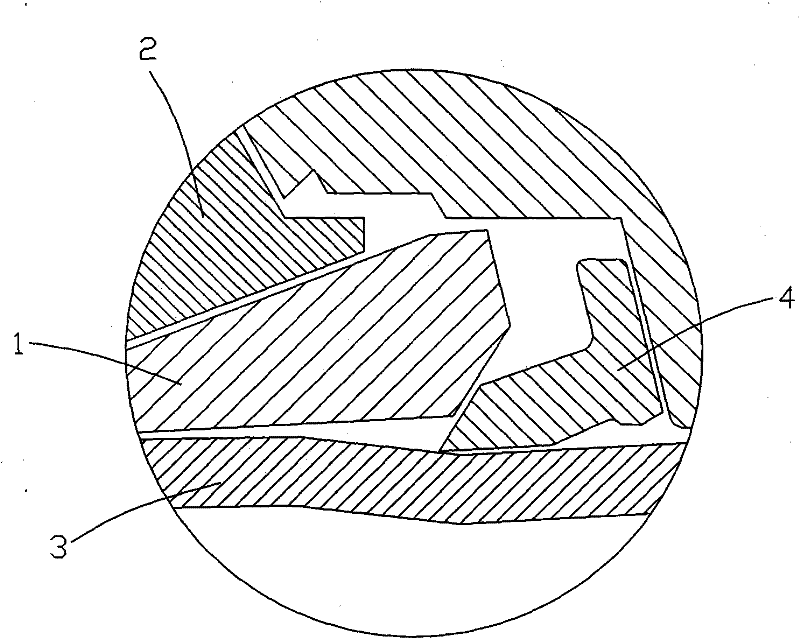

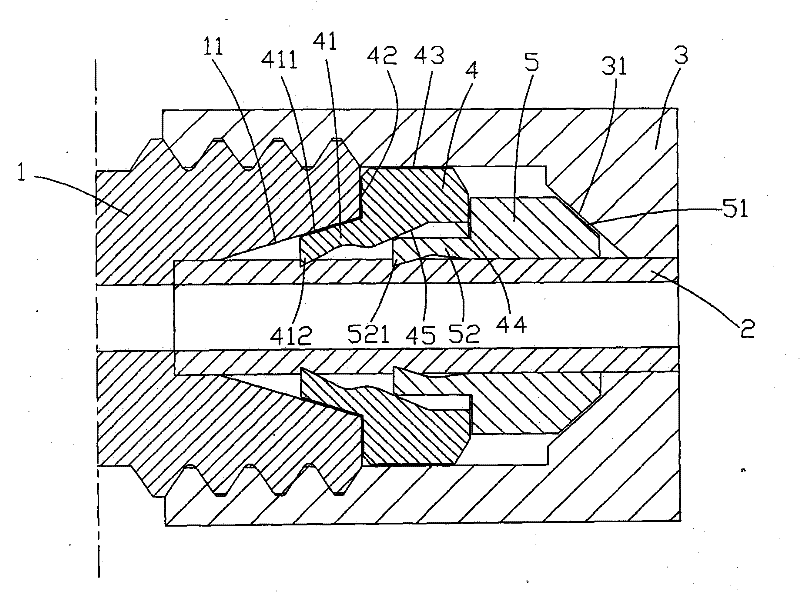

[0021] Such as figure 1 As shown, a double ferrule type pipe joint provided according to the present invention includes a joint 1, a pipe 2 mated with the joint 1, a nut 3 for tightly connecting the joint 1 and the pipe 2, a front ferrule 4 and a rear Ferrule 5, one end of nut 3 wide mouth is threadedly connected with joint 1, and one end of nut 3 narrow mouth is matched with pipe 2 diameters. Both the front ferrule 4 and the rear ferrule 5 are high-temperature-resistant metal parts, so they are suitable for connecting pipe joints in high-temperature working environments. The outer ring surface 411 of the hollow annular boss 41 of the front ferrule 4 is closely matched with the joint chute 11, the front edge 412 of the inner ring surface of the hollow annular boss 41 cuts into the body surface of the pipe 2, and the outer ring of the front ferrule 4 The ring stepped surface 42 and the outer ring horizontal surface 43 close the gap between the front edge of the joint chute 11 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com