Method for detecting quality of conductive sliding ring

A quality inspection method and technology for conductive slip rings, which are used in the measurement of electrical variables, measuring devices, and resistance/reactance/impedance measurements, etc., can solve the problem of not being able to show the change in the contact resistance between the brush and the slideway of the conductive slip ring.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

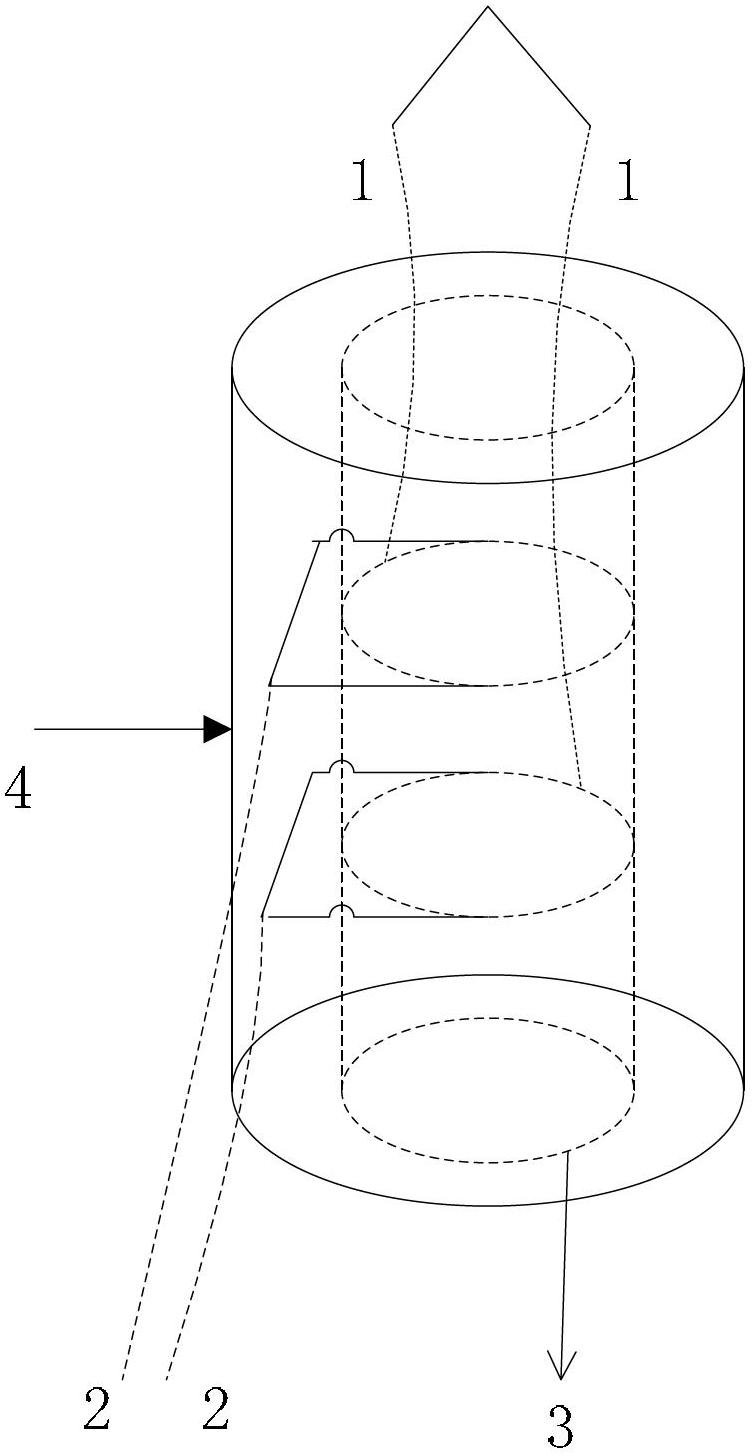

[0021] Specific implementation mode one: combine figure 1 and figure 2 Describe this embodiment mode, a kind of conductive slip ring quality detection method described in this embodiment mode, it comprises concrete steps as follows:

[0022] Place the conductive slip ring to be tested on the conductive slip ring test tool, so that the conductive slip ring runs at a constant speed of speed ω, and measure the dynamic resistance of the measured conductive slip ring as y(t) during the rotation of the conductive slip ring;

[0023] The rotation period of the above-mentioned conductive ring is T, θ 0 is the initial phase at the beginning of the test;

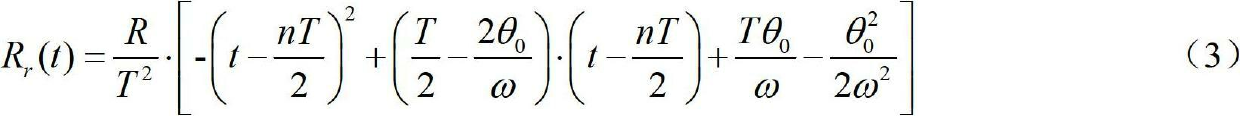

[0024] According to the total resistance of the conductive ring actually connected to the circuit is

[0025] R r ( t ) = R T 2 · [ - ...

specific Embodiment approach 2

[0036] Specific embodiment 2: This embodiment is a further limitation of the quality detection method of a conductive slip ring described in Embodiment 1. The total resistance R of the conductive ring actually connected to the circuit r The expression for (t) is obtained by the following method:

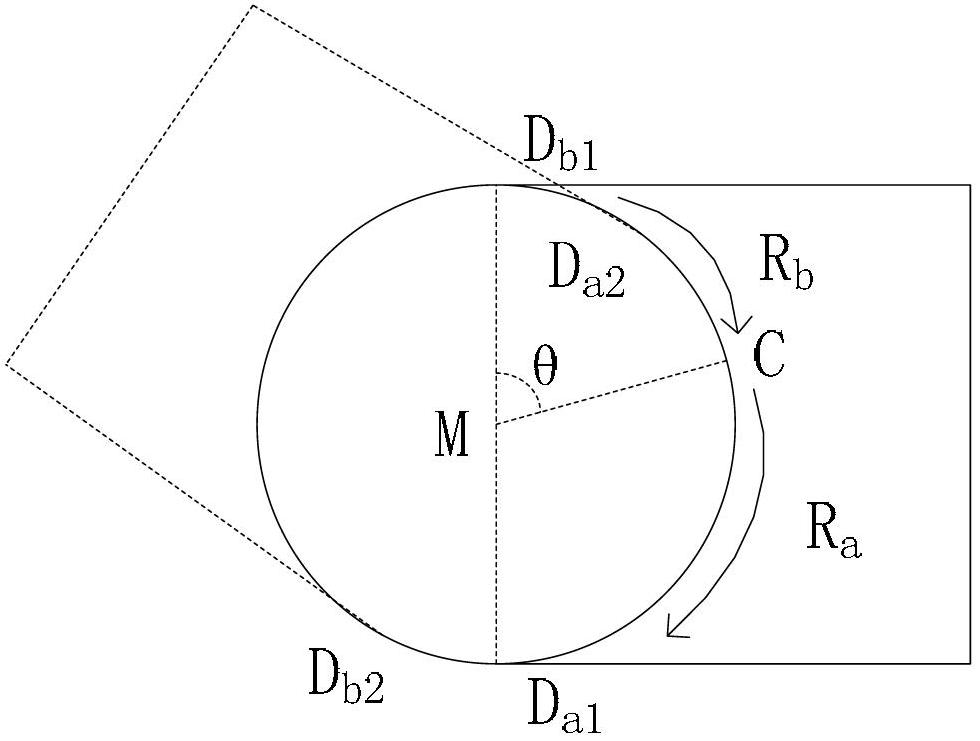

[0037] Define the contact point between the conductive ring lead wire 1 and the conductive slip ring as point C, point D a and point D b They are the two contact points between the "∏" type brush and the conductive ring, point M is the center position of the conductive ring, then point C and point D a The resistor between R a , point C and point D b The resistor between R b , R a with R b Connected in parallel, the rotation angle θ of the conductive ring corresponding to the time t is the angle formed by the line segment MC and the line segment MD, which is an acute angle;

[0038] R r (t), θ and R have the following relationship:

[0039] R ...

specific Embodiment approach 3

[0044] Specific embodiment three: This embodiment is a further limitation of the quality detection method of a conductive slip ring described in the first embodiment. According to the comparison between the ideal dynamic resistance R(t) of the conductive slip ring to be tested and the actual measured dynamic resistance y( t) and parameter R, calculate the resistance equivalent DC component R of the conductive slip ring 0 The process is:

[0045] Step 1. Obtain the ideal dynamic resistance change curve according to the ideal dynamic resistance R(t), obtain the actual dynamic resistance change curve according to the actually measured dynamic resistance y(t), discretize the two dynamic resistance change curves respectively, and the sampling interval is ΔT, Then the ideal periodic sequence R(i) is obtained after the ideal dynamic resistance change curve is discretized, i=1, 2, ... m; m is a natural number; the actual measurement sequence y(k) is obtained after the actual dynamic r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com