Method and system for monitoring foundation structure of wind power generation device

A technology of wind power generation equipment and basic structure, which is applied in the monitoring of wind power generators, wind power generation, installation/support configuration of wind power generators, etc. It can solve the problems of large data volume and tower instability, and achieve high utilization rate and low cost. The effect of pressure on data storage and processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

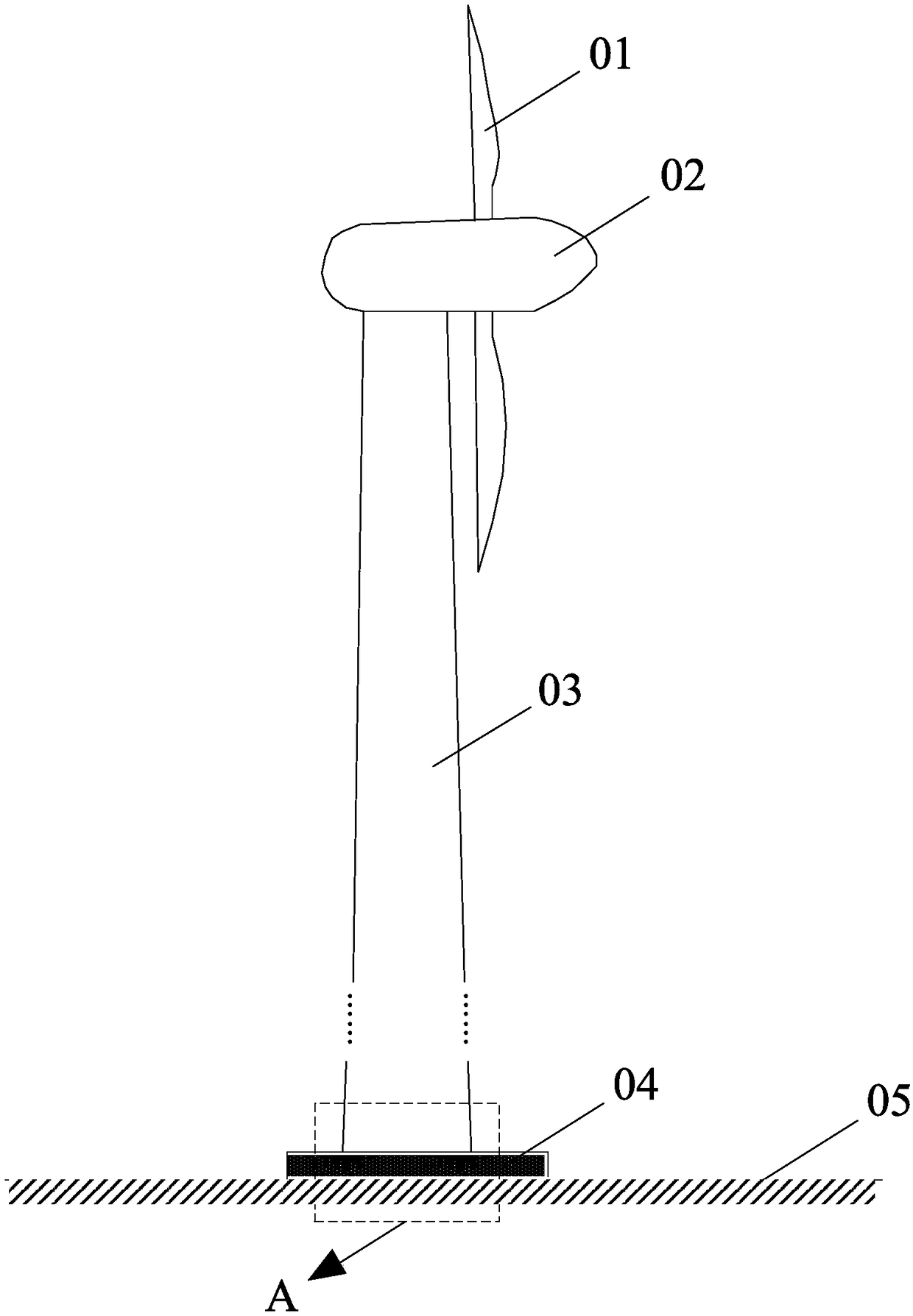

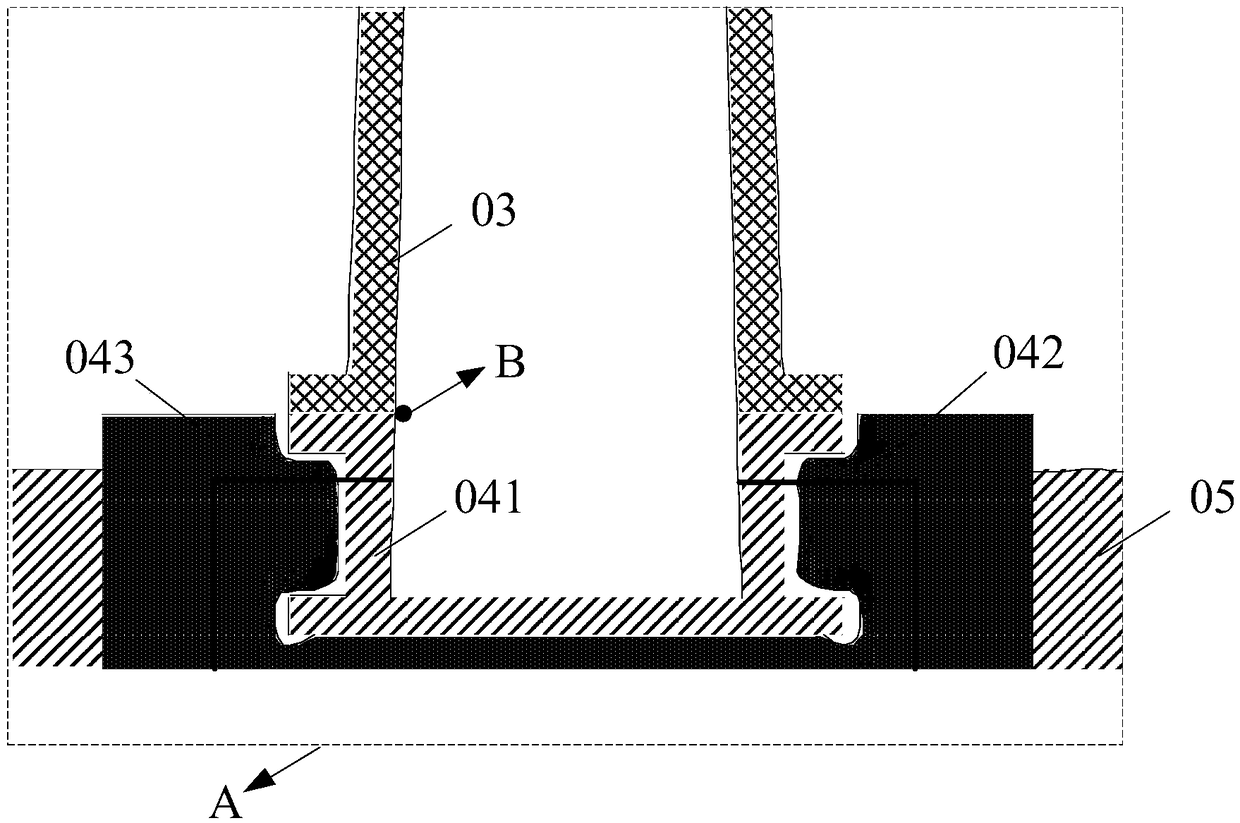

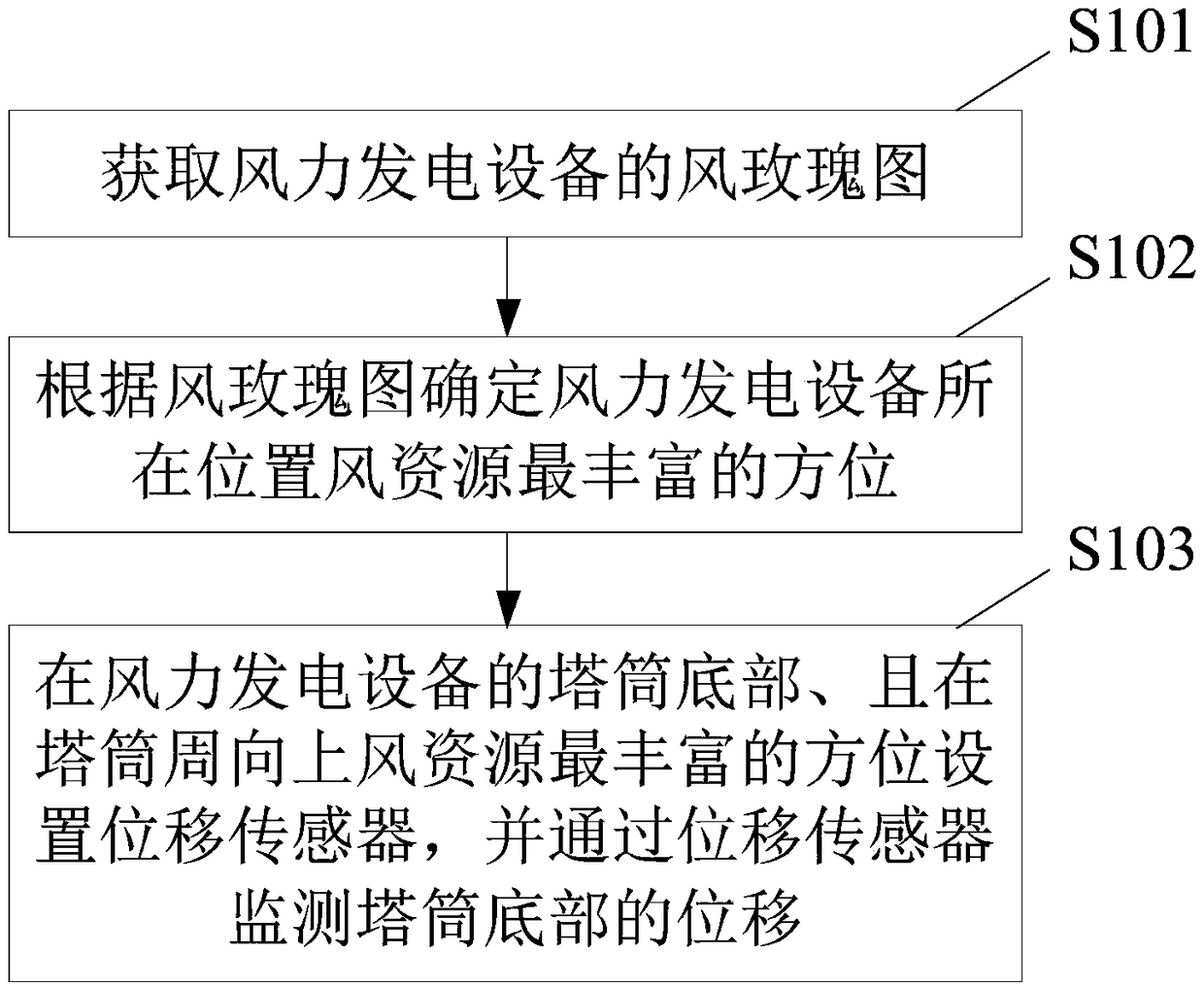

[0030] Figure 3A A flowchart of a method for monitoring the infrastructure of a wind power generation equipment according to an embodiment of the present invention is shown. Such as Figure 3A As shown, the method includes the following steps:

[0031] S101: Obtain a wind rose diagram of the wind power generation equipment.

[0032] S102: Determine the position with the most abundant wind resources at the location of the wind power generation equipment according to the wind rose diagram.

[0033] The wind rose diagram in this application can be a commonly understood "wind direction frequency rose diagram" (also referred to as "wind direction rose diagram" or "wind direction diagram"), a wind speed rose diagram, or a wind energy rose diagram.

[0034] The wind direction frequency rose chart can reflect the percentage of the number of occurrences of various wind directions in a certain period of time; for example Figure 3B The greater the distance from a point on a certain azimuth to ...

Embodiment 2

[0042] Figure 4A A flowchart of another method for monitoring the infrastructure of a wind power generation equipment according to an embodiment of the present invention is shown. Such as Figure 4A As shown, the method includes the following steps:

[0043] S201: Obtain a wind rose diagram of the wind power generation equipment.

[0044] S202: Determine the position with the most abundant wind resources at the location of the wind power generation equipment according to the wind rose diagram.

[0045] S203: At the bottom of the tower tube of the wind power generation equipment, and in the direction with the most abundant wind resources in the circumference of the tower tube.

[0046] For the above steps S201, S202 and S203, please refer to steps S101, S102 and S103 respectively for details.

[0047] S204: Determine whether the displacement of the bottom of the tower is greater than a first preset threshold. When the displacement of the bottom of the tower is greater than the first p...

Embodiment 3

[0058] Figure 5 It shows a schematic structural diagram of a monitoring system for a wind power generation equipment infrastructure according to an embodiment of the present invention. The monitoring system can be used to implement the monitoring method described in the first or second embodiment. Such as Figure 5 As shown, the monitoring system includes a first server 10, a displacement sensor 20, a data collector 30, and a second server 40.

[0059] The first server 10 is configured to obtain a wind rose diagram of the wind power generation equipment, the wind rose diagram includes at least one of a wind direction frequency rose diagram, a wind speed rose diagram, or a wind energy rose diagram. According to the wind rose diagram, determine the position with the most abundant wind resources at the location of the wind power generation equipment, and determine the setting position of the displacement sensor as the position with the most abundant wind resources. For details, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com