Garbage diversion reduction treatment process as well as equipment implementing same

A technology of waste treatment equipment and treatment process, which is applied in the waste conversion reduction treatment process, biomass waste conversion and reduction series devices, and main equipment fields, which can solve the problems of high transportation and processing costs, large land occupation, and lack of mobility. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

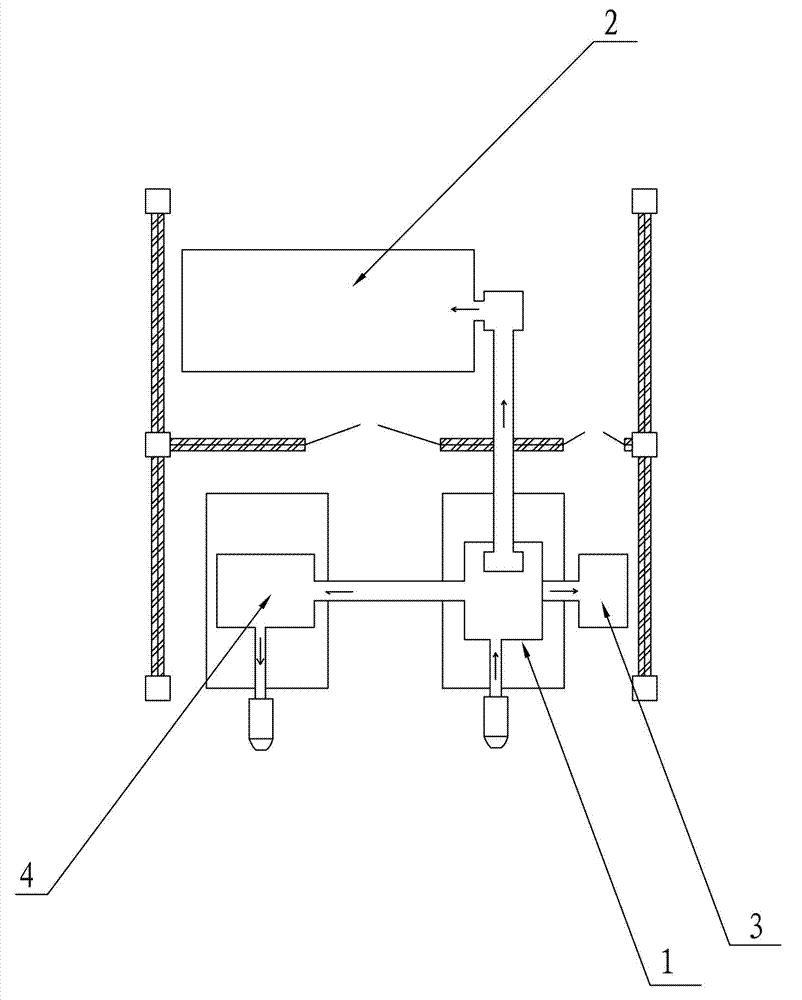

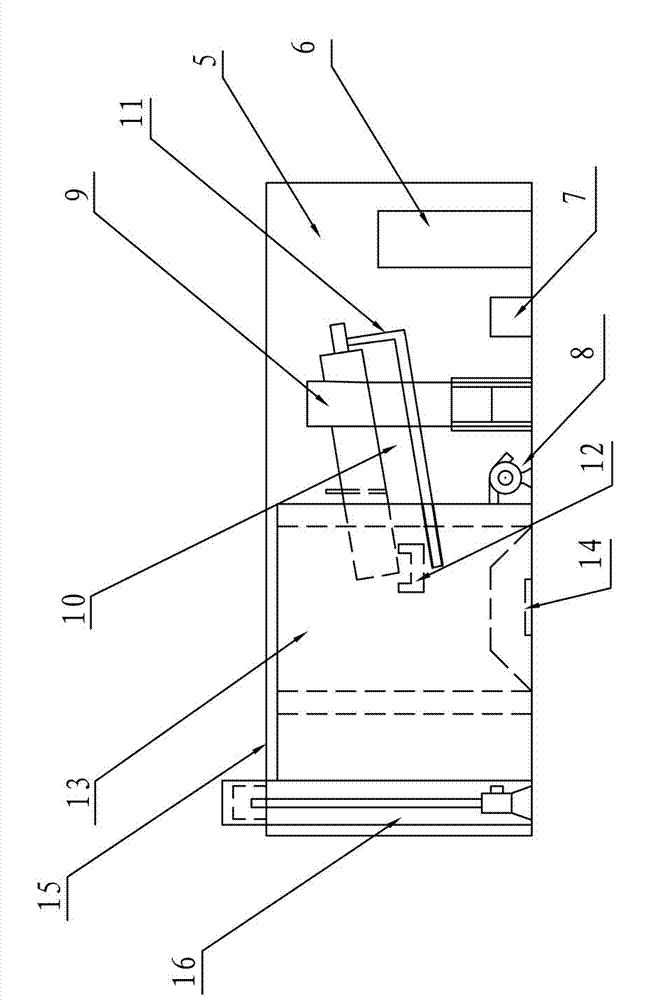

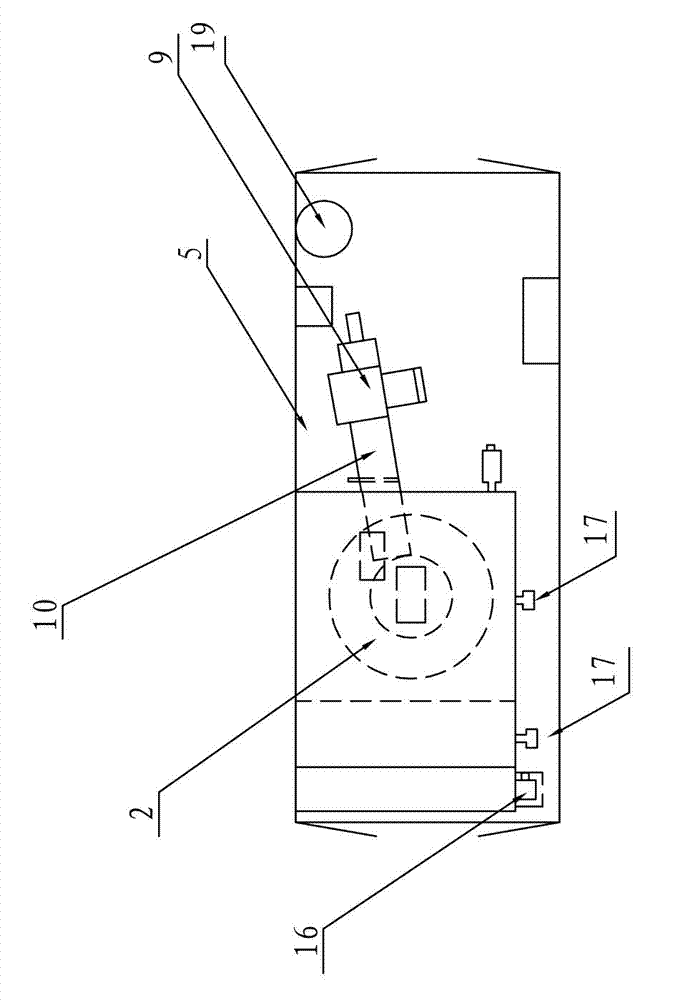

[0026] refer to Figure 1 ~ Figure 3 , the present invention provides a kind of garbage conversion reduction treatment process, it is characterized in that, comprises the following steps:

[0027] 1) Classify and select the domestic waste that needs to be processed through the waste classification system 1, and classify and select the domestic waste into waste to be recycled, biomass waste to be converted and reduced, and waste to be compressed and reduced;

[0028] 2) Send the biomass waste into the conversion and reduction device 2, send the waste to be recycled into the recycling collection box 3, and send the waste to be compressed and reduced into the compression and reduction device 4 for compression and packaging;

[0029] 3) The biomass waste treatment product in the conversion and weight reduction device 2 is made into a soil conditioner for soil improvement and landscaping, and the non-recyclable waste treatment product in the compression weight reduction device 4 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com