Reciprocating type automatic feeding mechanism

An automatic feeding and reciprocating technology, applied in the direction of conveyor, transportation and packaging, etc., can solve the problems of low efficiency, low labor efficiency, high one-time investment cost, etc., and achieve the effect of high efficiency and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

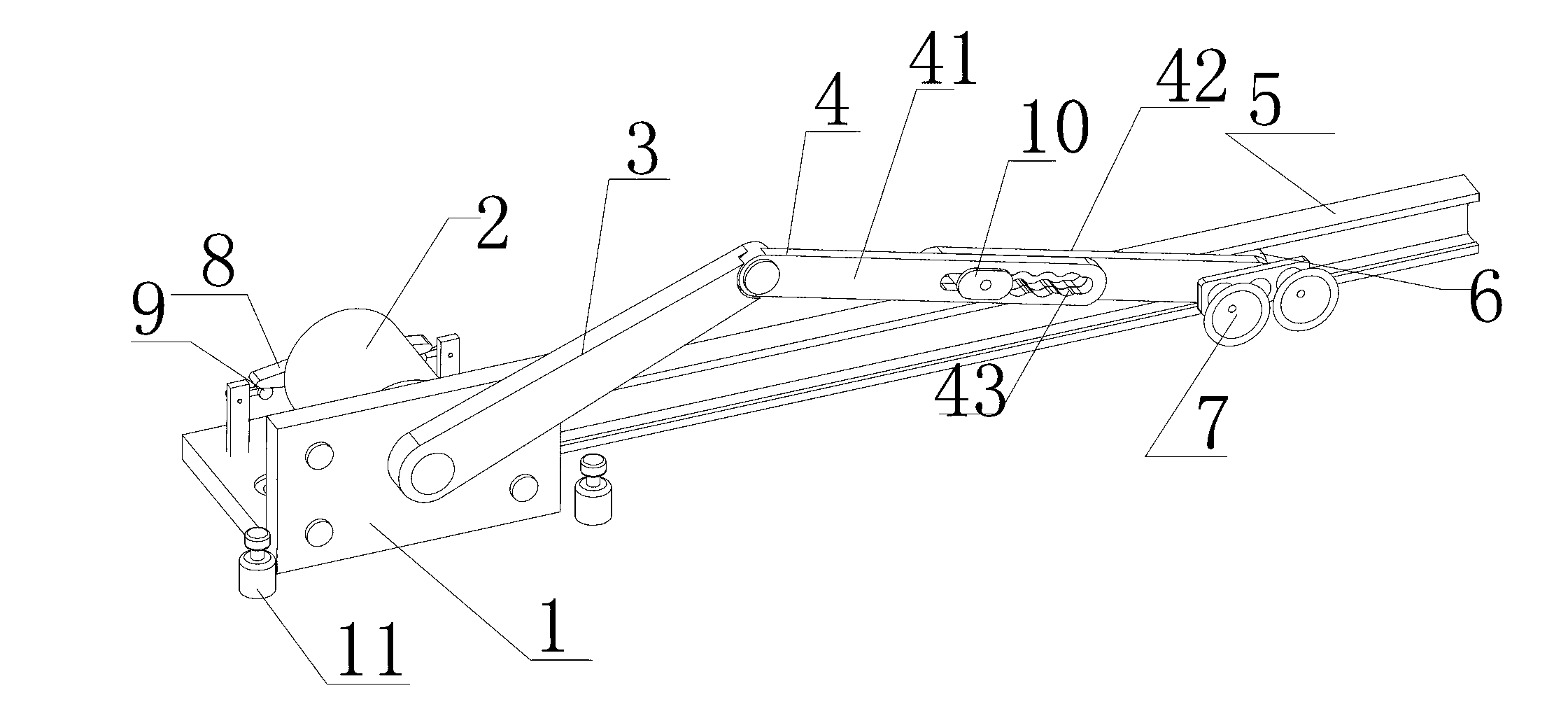

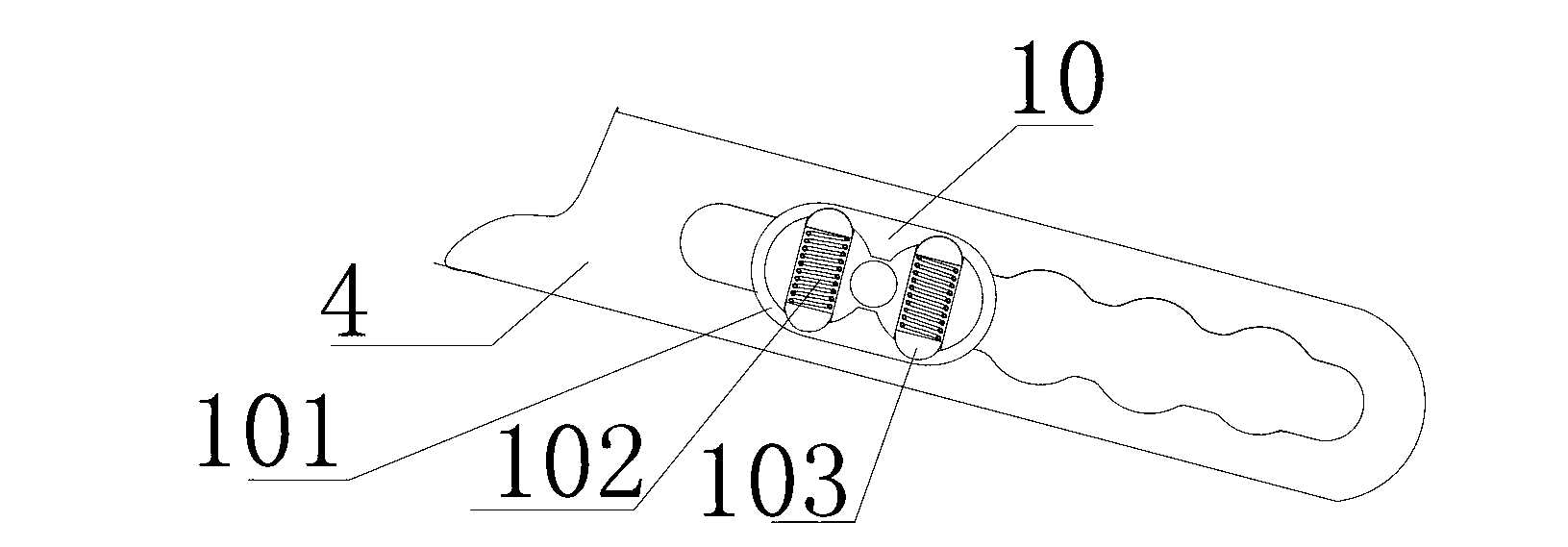

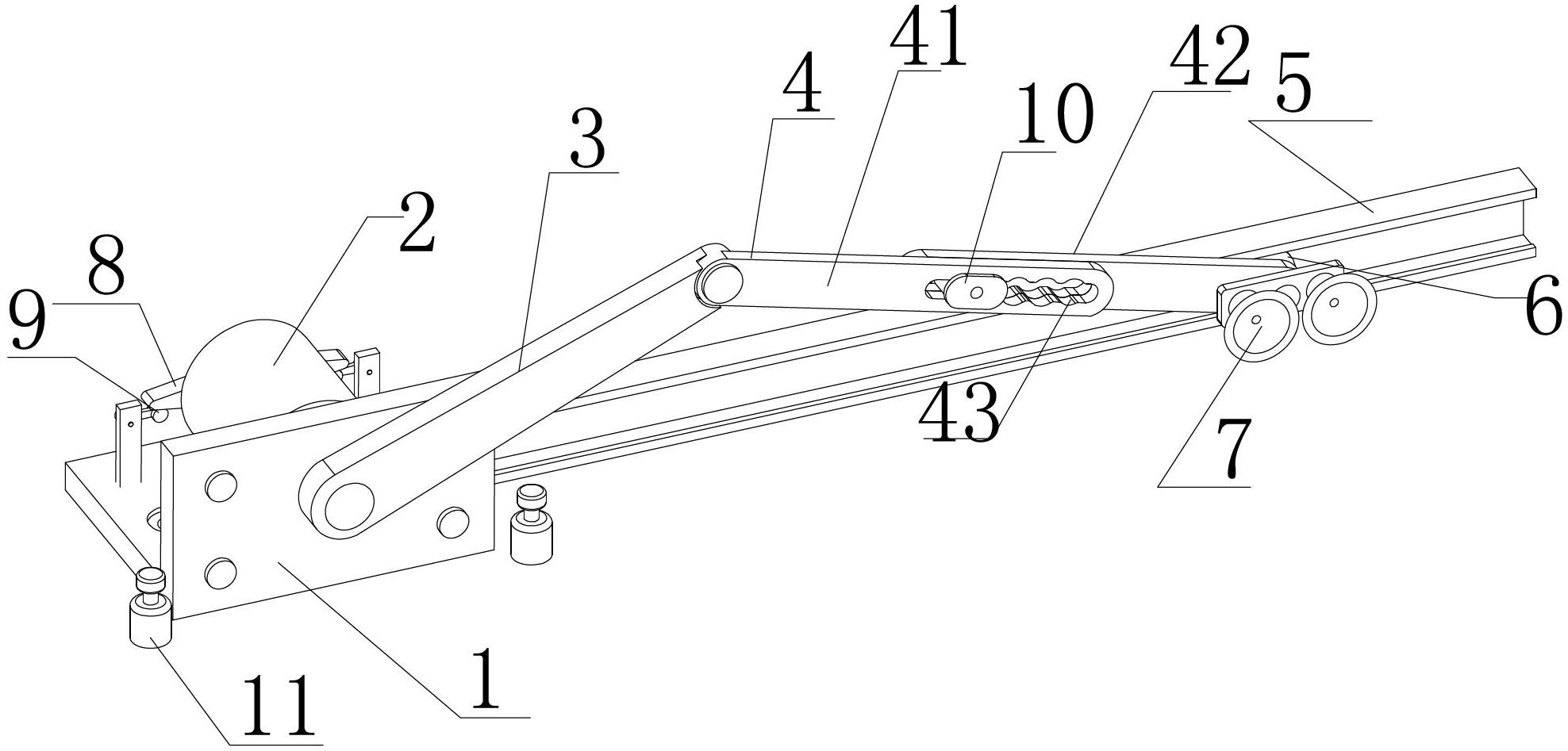

[0013] see figure 1 and figure 2 , the embodiment of the present invention includes:

[0014] A reciprocating automatic feeding mechanism, the reciprocating automatic feeding mechanism includes a mounting base 1, a swing cylinder 2, a driving arm 3, an adjustable follower arm 4, a guide rail 5, a roller 6 and a suction cup 7, and the mounting base 1 is installed There is a swing cylinder 2 with double output shafts, one output shaft of the swing cylinder 2 is fixed on one end of the driving arm 3, the other end of the driving arm 3 is movably connected to one end of the adjustable driven arm 4, and the other end of the adjustable driven arm Pulley 6 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com