An automatic feeding method and device for medical plastic needles

A technology of automatic feeding and plastic needles, applied in the field of medical devices, can solve the problems such as the ununiform position of plastic needle exhaust ports and low assembly efficiency, and achieve the effects of reducing artificial pollution, high assembly efficiency, and high cleanliness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

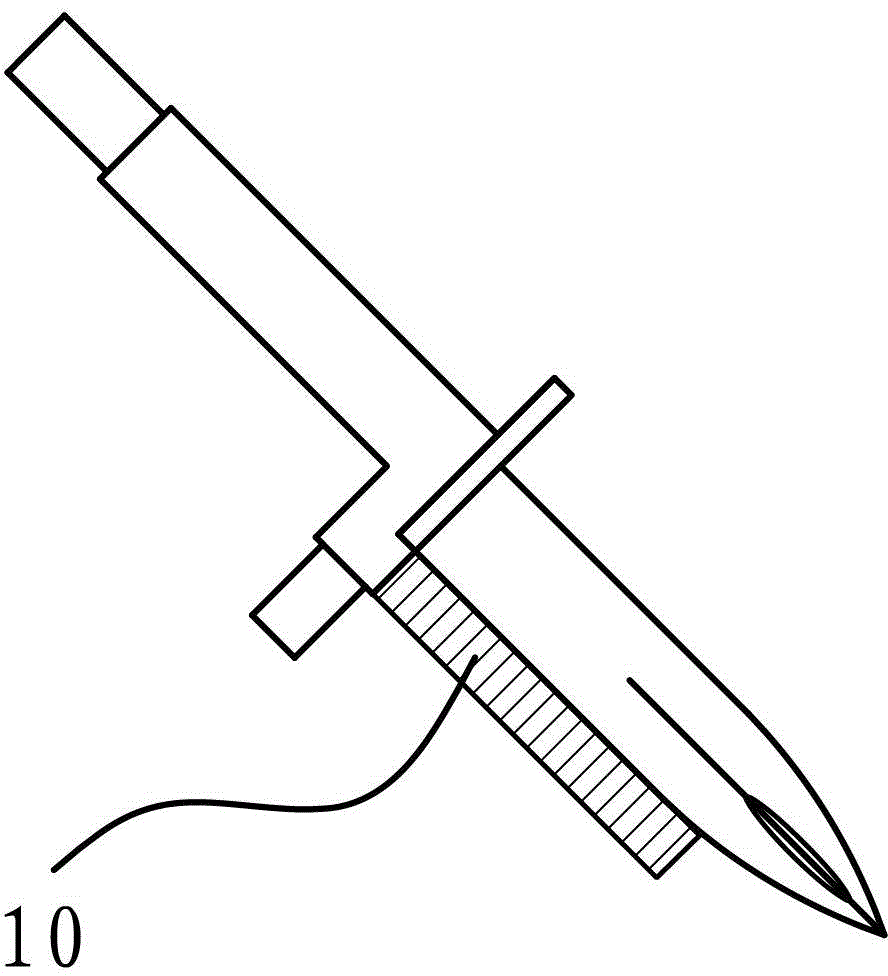

[0054] Such as Figure 1-Figure 5 Shown, the automatic feeding method of this medical plastic needle, this method comprises the following steps:

[0055] a. Material storage: put several plastic needles into the material storage area.

[0056] b. Screening material: there are several feeding channels between the material storage area and the screening material area, and the above-mentioned plastic needles lying and stacked in a disorderly manner enter each independent feeding channel. The plastic needles can be conveyed quickly and efficiently through multiple feeding channels. A number of plastic needles lying flat and stacked in disorder in the storage area enter the sieving area, and the excess plastic needles lying flat at the above-mentioned sieving area are discharged by vibration. In this embodiment, the storage area is located at the bottom of the screening area.

[0057] c. Hanging material: The appropriate amount of plastic needles output from the screening area e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com