Supercapacitor module structure, energy storage power supply device and rail vehicle/trackless vehicle

A technology of super capacitor module and energy storage power supply, which is applied in capacitors, electrical components, hybrid boxes/shells/packages, etc., to achieve the effect of maintenance safety, saving man-hours and materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

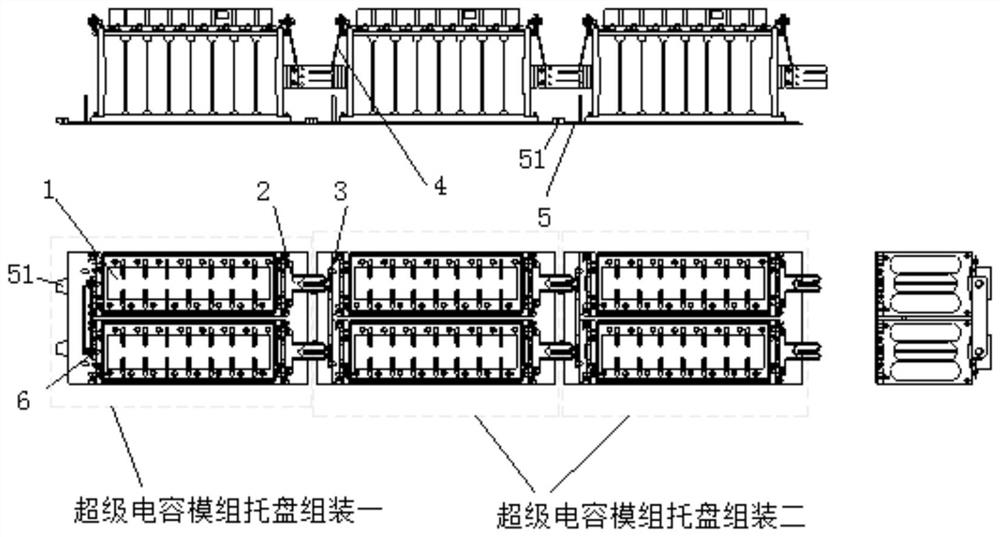

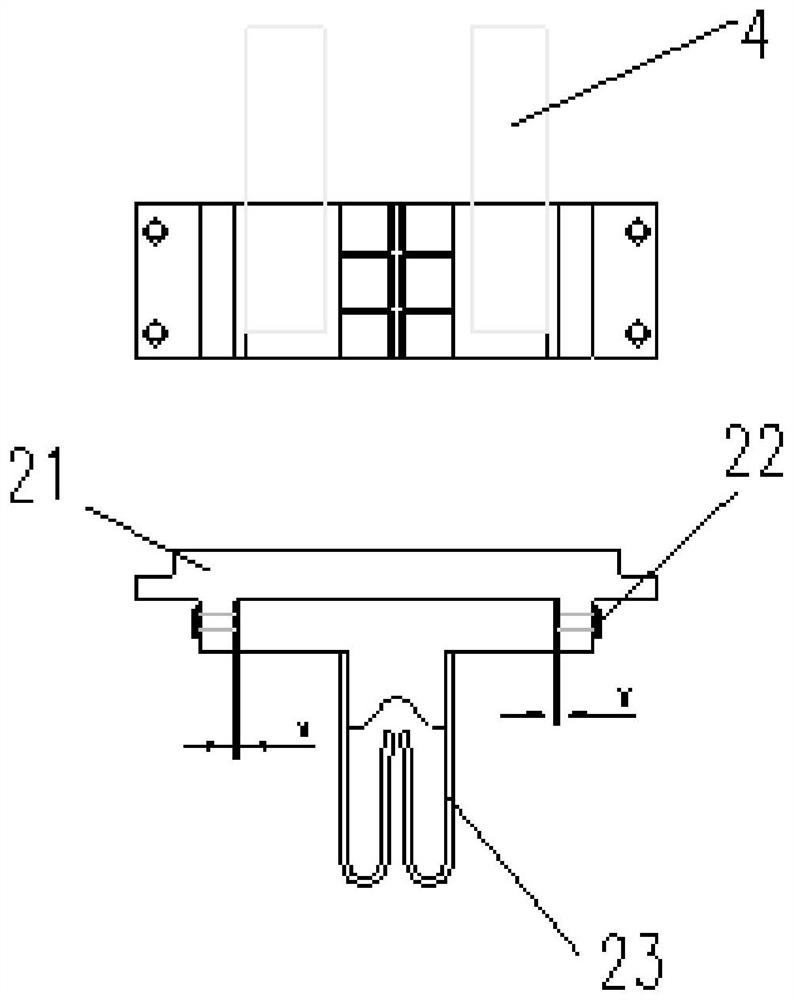

[0020] like figure 1 As shown, the supercapacitor module tray assembly 1 of the present invention: two supercapacitor modules 1 are installed on the module insulation tray 5, and one side of the two supercapacitor modules 1 is electrically connected by a fastening method of copper bars 6, Two reed assemblies 2 are installed on the other side of the two supercapacitor modules 1. The reed assemblies 2 are installed at the lower part of the output of the supercapacitor module 1. Copper flat wire 4 is connected and fastened, soft copper flat wire 4 is reserved for expansion and contraction of x mm for reed assembly 2 and can be moved laterally ± x mm;

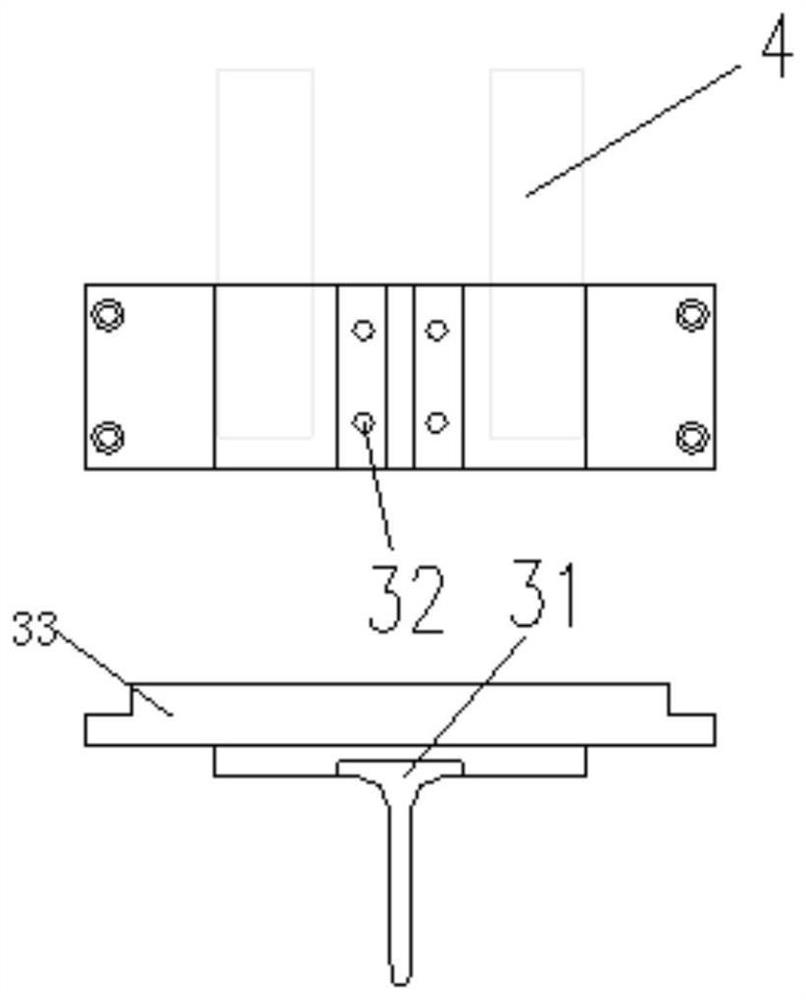

[0021] Supercapacitor module tray assembly 2: two supercapacitor modules 1 are installed on the module insulation tray 5, one side of the two supercapacitor modules 1 is installed with a knife assembly 3, and the other side of the two supercapacitor modules 1 Install reed assembly 2 on the side; knife assembly 3 and reed assembly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com