Sewing machine with rotary LED (Light Emitting Diode) lamp

A technology of LED lights and sewing machines, which is applied in the direction of sewing machine components, sewing equipment, lighting device parts, etc., and can solve the problems of high energy consumption and inability to illuminate the light

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing and embodiment the invention is described in detail:

[0018] The present invention designs a sewing machine with a rotating LED lamp, which can determine the required lighting position through the photosensitive sensor on it, and then the LED lamp automatically rotates to the corresponding position for lighting.

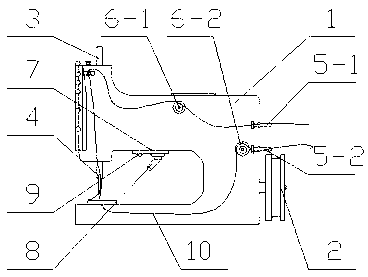

[0019] As an embodiment of the present invention, the present invention provides a structural schematic diagram such as figure 1 A sewing machine with a rotating LED light is shown, comprising a sewing machine main body 1, a belt pulley 2, a needle swing bar 3 and a thread to be sewn 10, the machine needle swing bar 5 is installed on the upper part of the sewing machine main body 1, and the machine needle swings The organic needle 6 is installed at the bottom of the bar 5, and the lower part of the sewing machine main body 1 side is provided with a belt pulley 4. There are two lifting and pressing cams on the sew...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com