Spreading machine, and method and device for controlling material level of spreading machine

A technology of material level control and paver, which is applied in roads, constructions, road repairs, etc., and can solve problems such as large changes in the speed of the material distribution screw, segregation of asphalt mixture materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. It should be pointed out that the description and sequence of specific structures in this section are only descriptions of specific embodiments, and should not be considered as limiting the protection scope of the present invention.

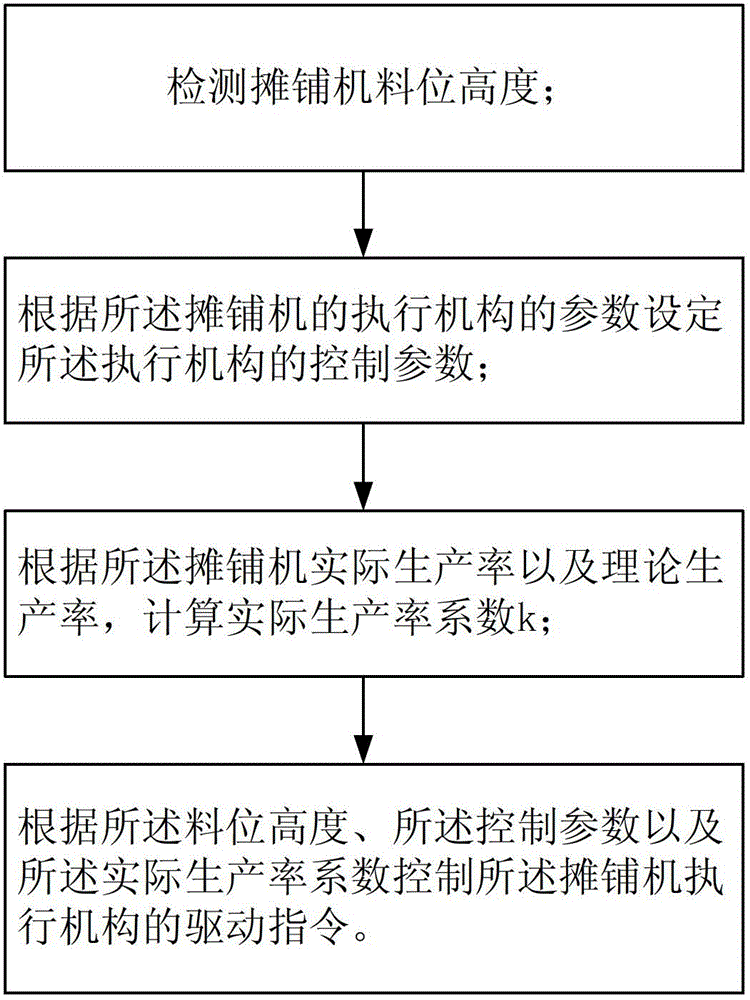

[0042] Please refer to figure 1 , figure 1 It is a flow chart of an embodiment of a paver material level control method according to the present invention, the method comprising:

[0043] Step 1, detecting the material level height of the paver;

[0044] Step 2, setting the control parameters of the actuator according to the parameters of the actuator of the paver;

[0045] Step 3, according to the actual productivity of the paver and the theoretical productivity, calculate the actual produc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com