Inserting-type emergency cut-off valve for liquefied natural gas cylinder

A liquefied natural gas, cartridge technology, applied in valve details, safety valves, balance valves, etc., can solve the problems of cumbersome assembly, maintenance, failure of the restrictor valve, unsuitable system integration, etc., to achieve low installation and maintenance costs, Improve energy efficiency, compact and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The preferred embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

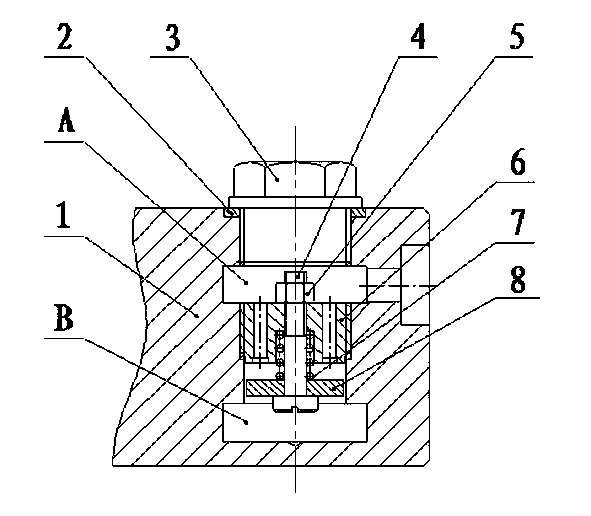

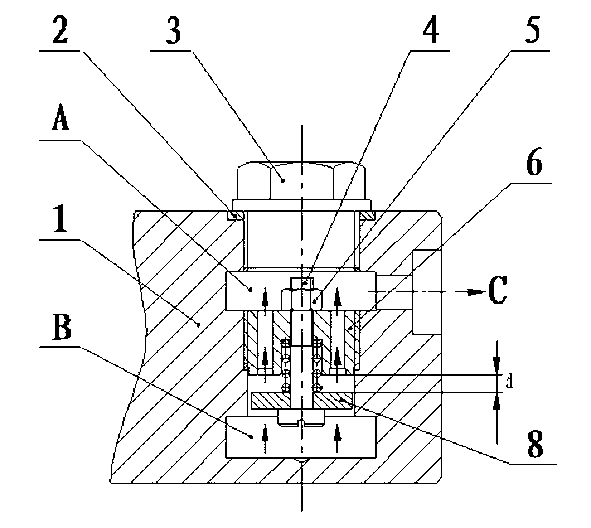

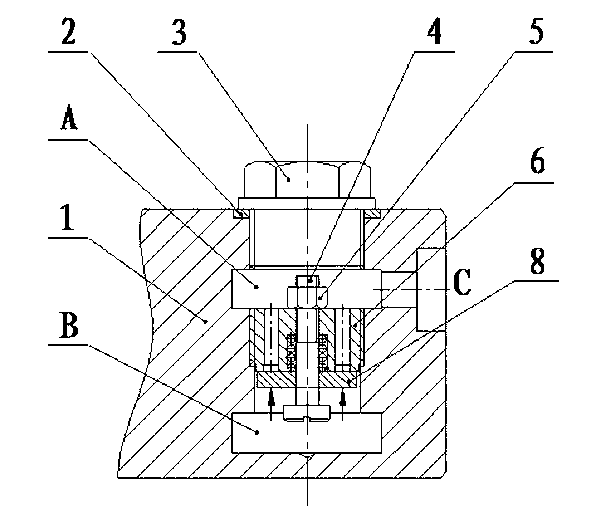

[0021] Referring to the accompanying drawings, a plug-in emergency shut-off valve for liquefied natural gas cylinders includes a distribution head 1, a seal 2, a plug gland 3, an adjusting nut 4, a bolt 5, a screw seat 6, a spring 7, and a valve plate 8 .

[0022] The screw seat 6 is designed as a threaded cylinder for the outer cylindrical surface, and the axial design of the screw seat 6 has six through holes 9 that are equally divided into 60° and a central through hole 10 that is designed with a step stop in the middle of an inner wall.

[0023] The valve plate 8 and the spring 7 are sequentially set into the bolt 5 from the front end of the bolt 5, and the bolt 5 with the valve plate 8 and the spring 7 is installed into the center through hole 10 of the screw seat 6 from the lower end of the screw seat 6, and one end of the spring 7 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com