Self-locking switch for pulling out press plate

A technology of self-locking switch and pressure plate, which is applied to the parts of the tumble switch/rocker switch, etc., can solve the problems of easy safety accidents, saw blade breakage, jamming, etc., and achieve good arc extinguishing performance, reliable working performance, small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

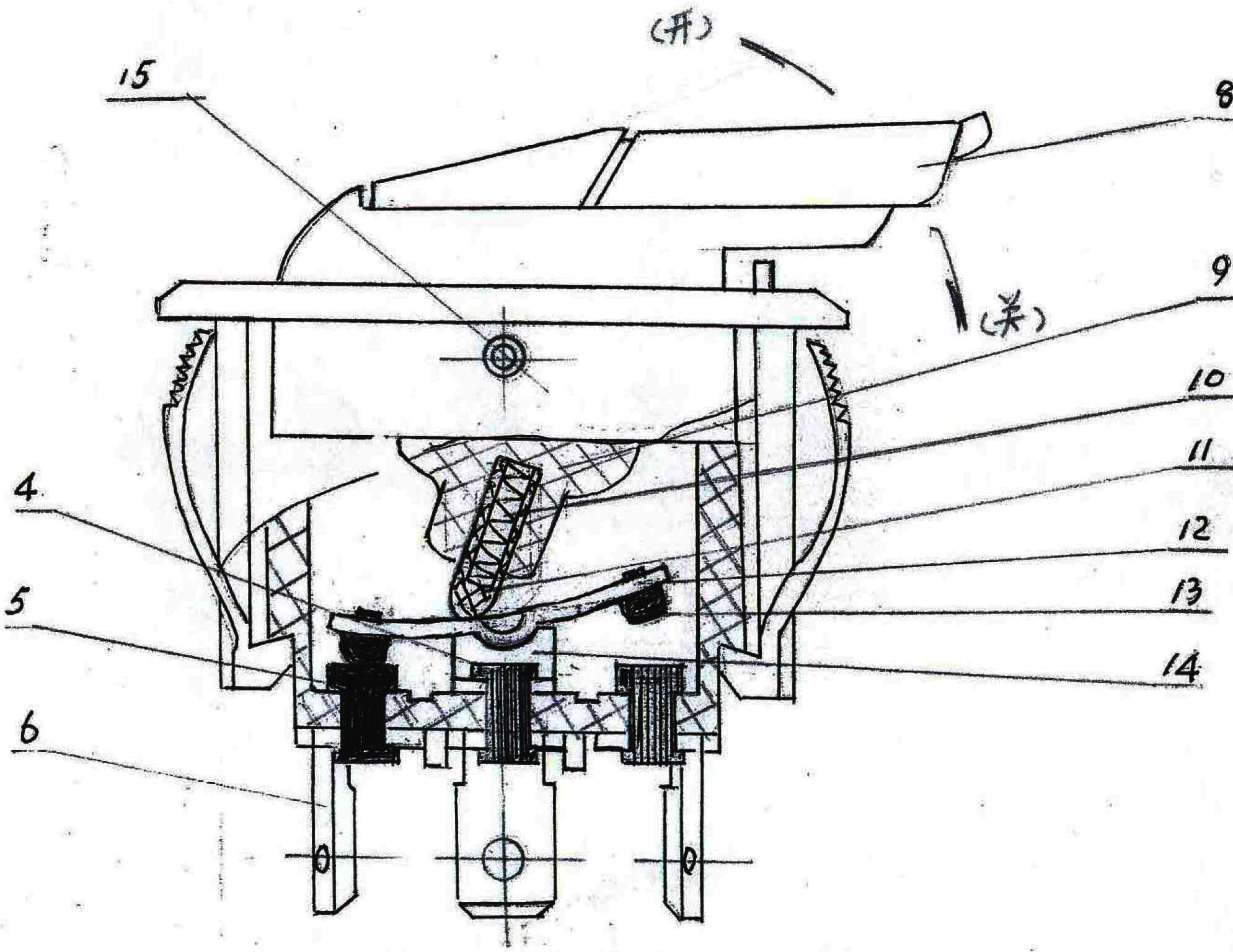

[0010] The present invention will be further explained below in conjunction with the drawings.

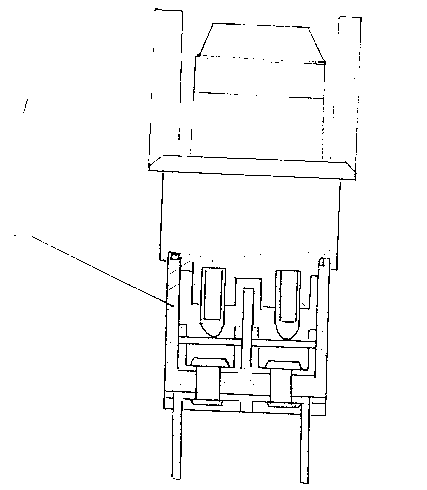

[0011] Such as figure 1 with figure 2 As shown, a self-locking switch with a pressure plate pulling out of the present invention includes a pressure plate button 8, a housing 1, a base 3, a movable seat 9, a moving piece 12, a bracket 14 and a spring 10. The upper part of the movable seat 9 and the pressure plate button 8 is connected, the bottom of the movable seat 9 is connected with the spring 10, the head of the spring 10 is connected with the moving plate 12, the spring 10 is provided with a spring core 11, and a bracket 14 is provided under the moving plate 12, and the bracket 14 is U The two ends of the movable plate 12 are provided with a first contact 13 and a second contact 5 respectively. The support 14 is riveted on the base 3 by copper rivets 4, and the pressing plate button 8 is connected to the housing 1 by a pin 15.

[0012] The present invention adopts the lever-type ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap