Steel shell lithium battery

A lithium battery and steel case technology, applied in the field of steel case batteries, can solve problems such as short circuit, battery overheating, negative electrode lugs contacting positive electrodes or positive and negative electrodes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with specific embodiments and accompanying drawings, but the embodiments of the present invention are not limited thereto.

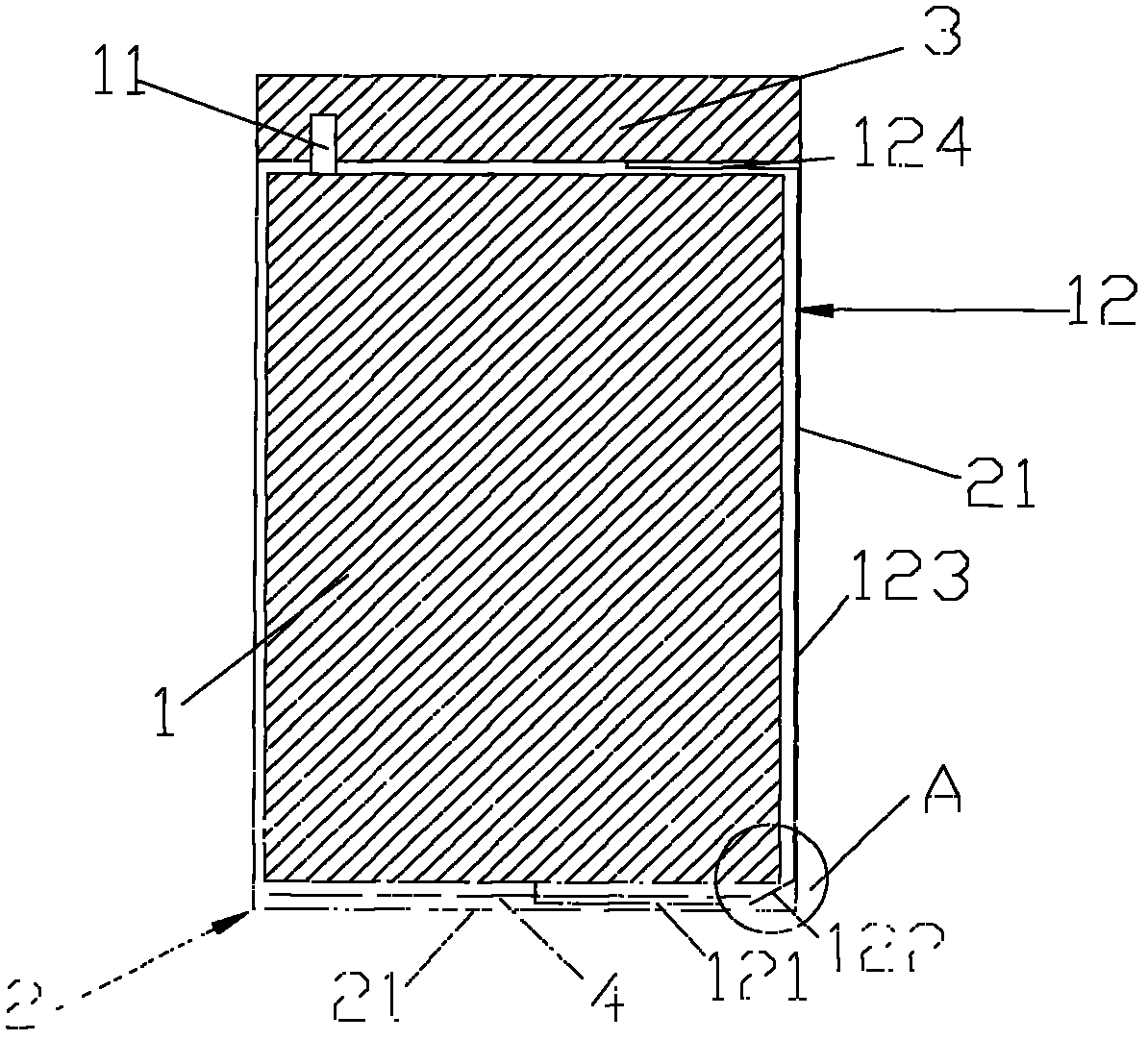

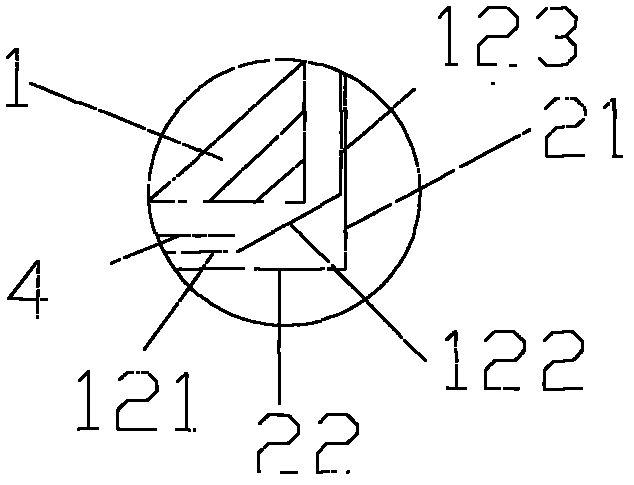

[0027] Such as figure 1 and figure 2 As shown, a steel case lithium battery includes a battery cell 1, a steel case 2 accommodating the battery cell 1 and a cap 3 connected to the steel case 2, and the battery cell 1 is provided with a positive electrode tab 11 And the negative pole tab 12, the negative pole tab 12 is connected to the bottom of the battery cell 1, an insulating gasket 4 is provided between the bottom of the battery core 1 and the steel shell 2, and the insulating gasket 4 is close to the steel shell The wall 21 is provided with a gap corresponding to the position where the negative pole tab 12 protrudes.

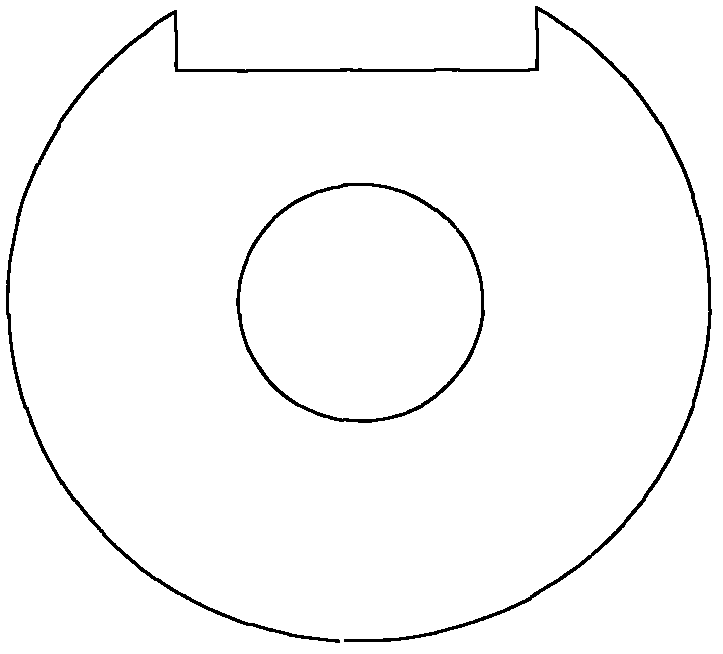

[0028] Wherein, the shape of the insulating spacer 4 is circular, and the shape of the gap is a rectangular groove ( image 3 ), arc-shaped groov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com