Beam tube sampling head protection device

A protection device and a sampling head technology, applied in the mechanical field, can solve problems such as the bending of the bundle tube and the failure to extract gas normally, and achieve the effect of avoiding clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

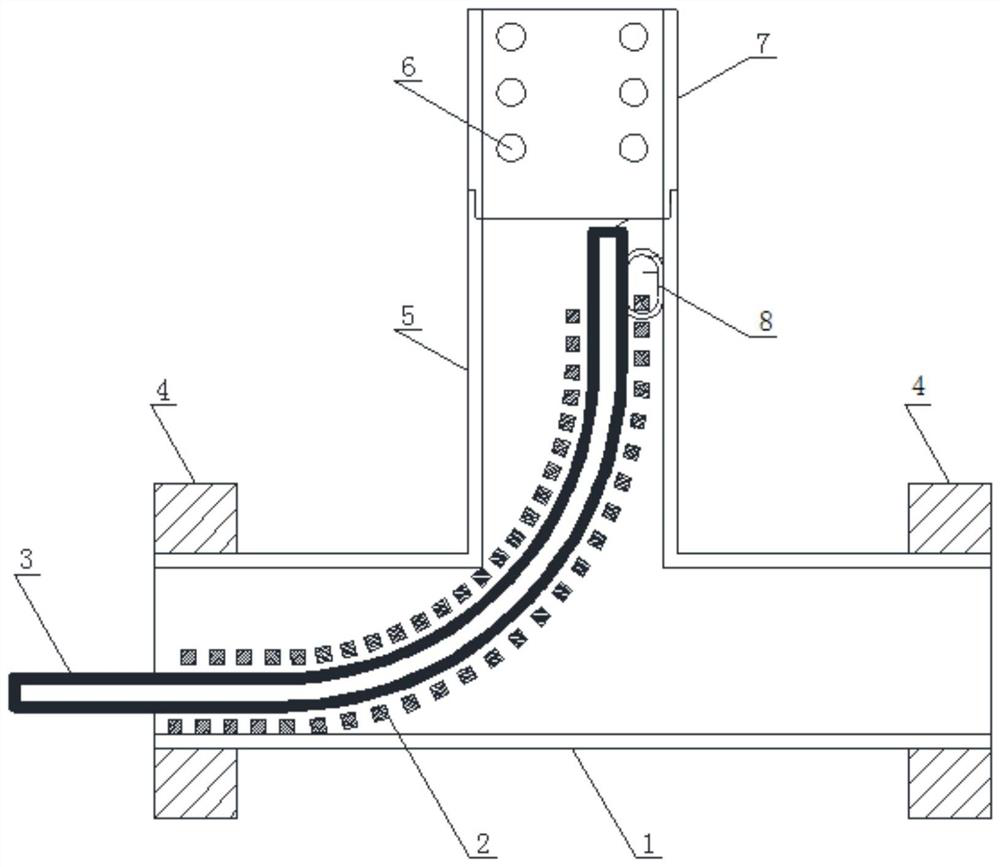

[0018] figure 1 It is a structural schematic diagram of the present invention, as shown in the figure, the bundle tube sampling head protection device in this embodiment includes a bundle tube 3, interconnected horizontal tube sections 1 and vertical tube sections 5, and the bundle tube 3 consists of a horizontal tube section 1 at one end Penetrating until the vertical pipe section 5, the bundle pipe 3 is covered with a support frame 2 for keeping the bundle pipe 3 unimpeded, and the end of the vertical pipe section 5 is detachably provided with a dust-proof ventilation sleeve 7, Prevent the sampling head of the bundle tube 3 from inhaling impurities to cause blockage, and at the same time prevent excessive impurities from entering the bundle tube 3 and affecting the permeability of the bundle tube 3 .

[0019] In this embodiment, the horizontal pipe section 1 and the vertical pipe section 5 form a connected three-way joint form, and the two ends of the horizontal pipe section...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com