Improved voice coil motor

A voice coil motor and coil technology, which is applied to electrical components, electromechanical devices, etc., can solve the problems of easy deformation, waste products, weak strength of the shrapnel, etc., and achieve the effect of not easy permanent deformation, reducing manufacturing costs, and improving yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

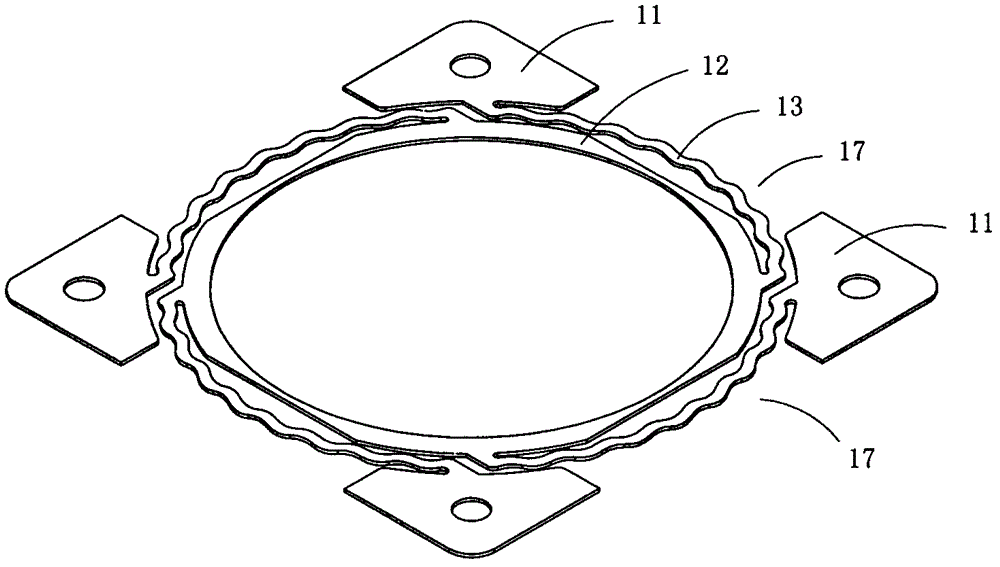

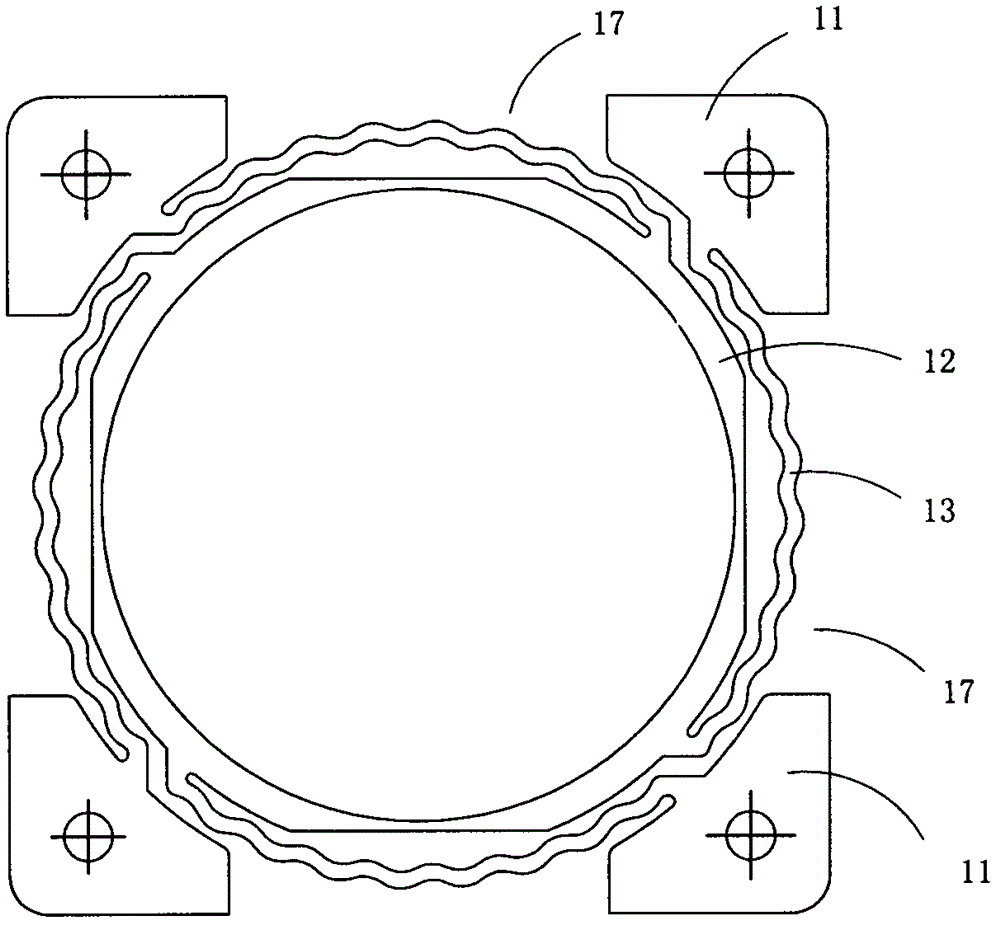

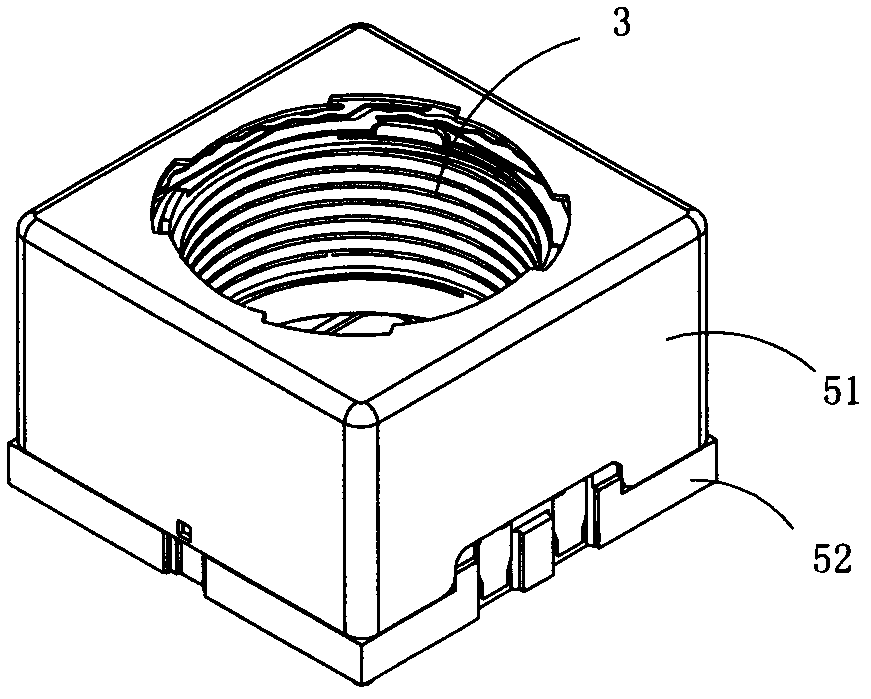

[0026] Figure 3 to Figure 6 A first embodiment of the invention is shown, in which image 3 It is a schematic diagram of a three-dimensional structure of the first structure of the present invention; Figure 4 yes image 3 An exploded view of the voice coil motor shown; Figure 5 yes image 3 A schematic diagram of the three-dimensional structure of the upper shrapnel in the voice coil motor shown; Image 6 yes Figure 5 A front view of the upper shrapnel shown.

[0027] This embodiment is a voice coil motor, see Figure 3 to Figure 6 , including an upper elastic piece 1, an upper elastic piece mounting frame 2, a lens carrier 3, a lower elastic piece 55, an upper cover 51, a base 52, a magnet assembly 53 and a coil 54; the base 52 and the upper cover 51 form a housing, and the lens The carrier 3 is arranged between the upper elastic piece 1 and the lower elastic piece 55, the magnet assembly 53 includes four rectangular magnets made of permanent magnets, and the four ...

Embodiment 2

[0037] Figure 7 with Figure 8 A second embodiment of the invention is shown, in which Figure 7 It is a schematic diagram of a three-dimensional structure of the upper elastic piece in the second structure of the present invention; Figure 8 yes Figure 7 A front view of the upper shrapnel shown.

[0038] This embodiment is basically the same as Embodiment 1, the difference is: see Figure 7 with Figure 8 As shown, in this embodiment, a connecting plate 18 is provided between two adjacent fixing areas 11 , and the connecting plate 18 and the fixing areas 11 are located on the same plane. The reinforcing plates 14 are located at the peripheral edges of each fixing area 11 and each connecting plate 18 . The connection plate 18 improves the overall strength of the upper elastic piece 1 to a certain extent, but because the upper elastic piece 1 is very thin, the strength improvement is still very limited, and the overall strength must be improved as much as possible by th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com