Liner having an integrated electrode

A sleeve and electrode technology, applied in the field of sleeves, can solve the problems of cost, high sealing, troublesome manufacturing and wearing comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

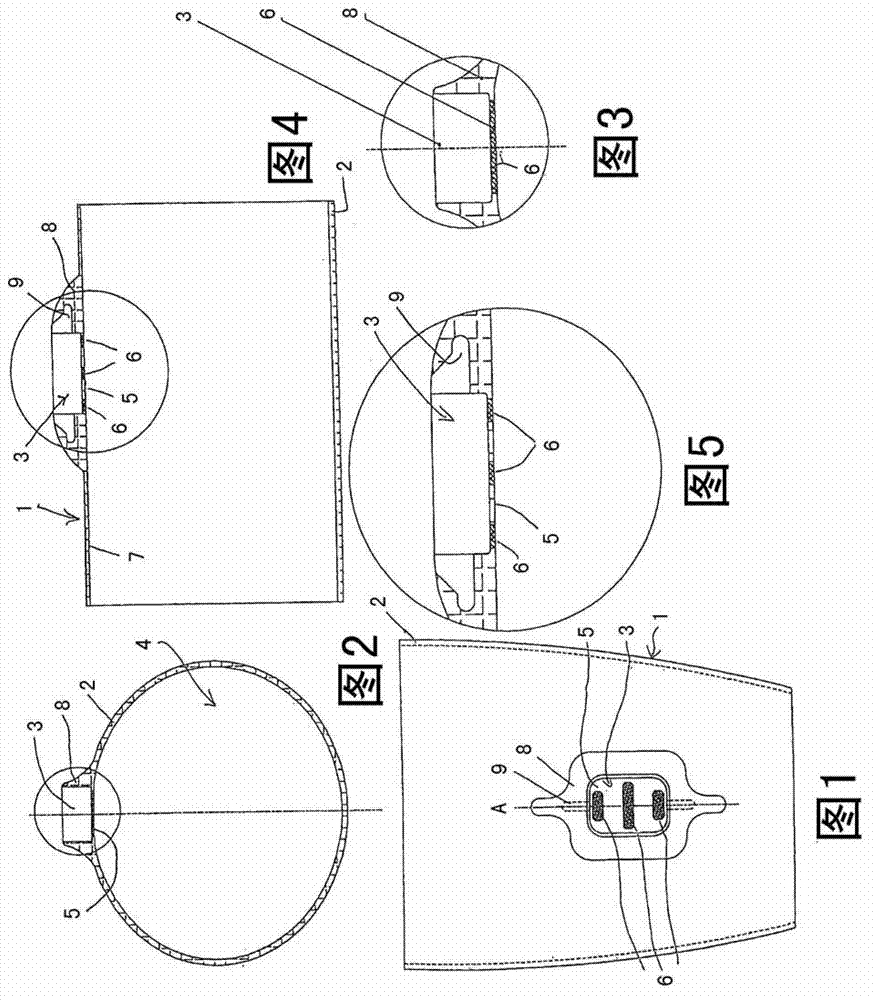

[0023] From Figures 1 to 5 It can be seen from the bushing section shown in that it is configured with a seamlessly closed wall 2 and tapers in the usual manner funnel-shaped towards the distal end. A receptacle 3 is formed in the material of the wall 2 in the form of a cavity open radially outwards, which is closed to the inner space 4 of the bushing with a thin wall section 5 as the bottom of the recess 3 . In the wall section 5 there are three electrically conductive sections 6 which are spaced apart from one another and are separated from one another by the non-conductive material of the bushing 1 . The electrically conductive section is formed in one piece with the material of the wall section 5 , so that a flat and continuous inner wall 7 is also present in the region of the receptacle 3 , as in particular image 3 and 5 shown.

[0024] Figures 2 to 5 It is shown that the receptacle 3 is delimited by an edge 8 which is formed by a material thickening of the wall of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com