Method for preventing molten iron of torpedo tank from being sprinkled due to reverse rotation

A technology of torpedo tank and reverse rotation, which is used in casting molten material containers, metal processing equipment, casting equipment, etc., can solve problems such as hidden safety hazards, low reliability, and distortion of zero limit signal detection, to ensure safe production. , avoid accident losses, improve the effect of reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing.

[0016] The specific implementation steps of the method for preventing the torpedo tank from reversely sprinkling iron in the present invention are:

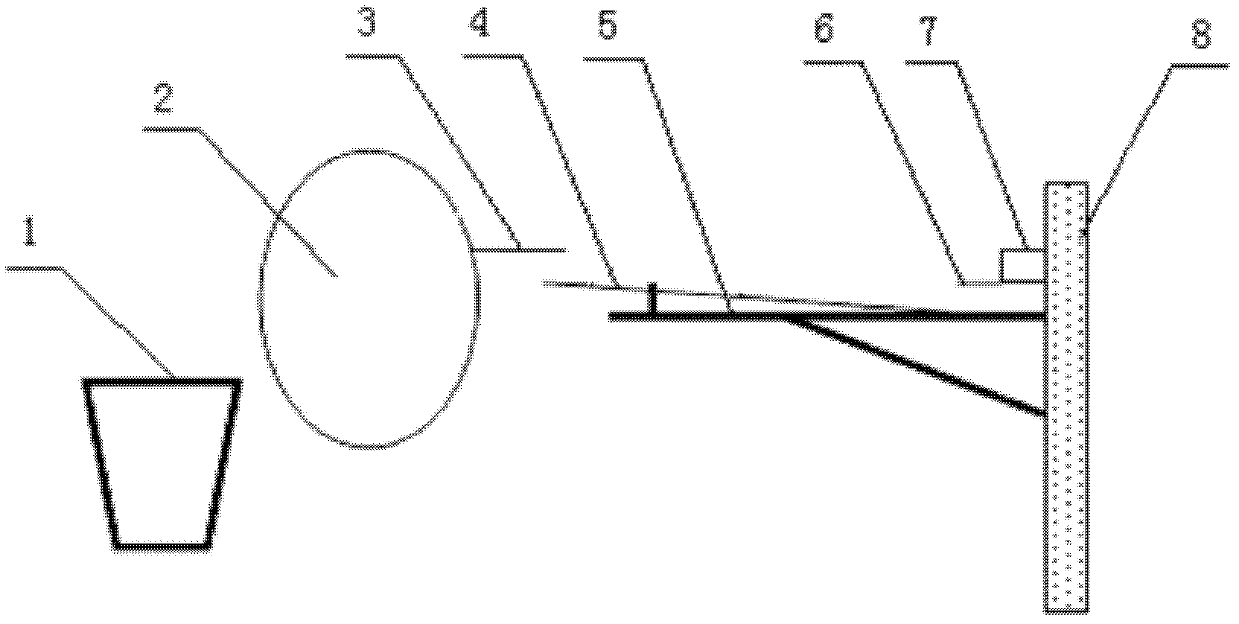

[0017] 1. The torpedo tank 2 is located on the right side of the molten iron tank 1. When the iron is folded, the torpedo tank should turn to the left in the forward and overturning direction, that is, turn to the direction of the molten iron tank 1. For avoiding the reverse of torpedo tank, so at first on the maximum diameter position of tank body on the right side of torpedo tank 2, a reverse trigger baffle plate 3 is welded.

[0018] 2, a travel switch 7 is installed on the factory building wall 8 of pouring cans opposite to the trigger baffle plate 3 of the torpedo tank 2, and a trigger touch plate 6 is provided below the travel switch 7. In order to ensure the accuracy of triggering, the installation height of travel swi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com