Patents

Literature

40results about How to "Avoid baking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

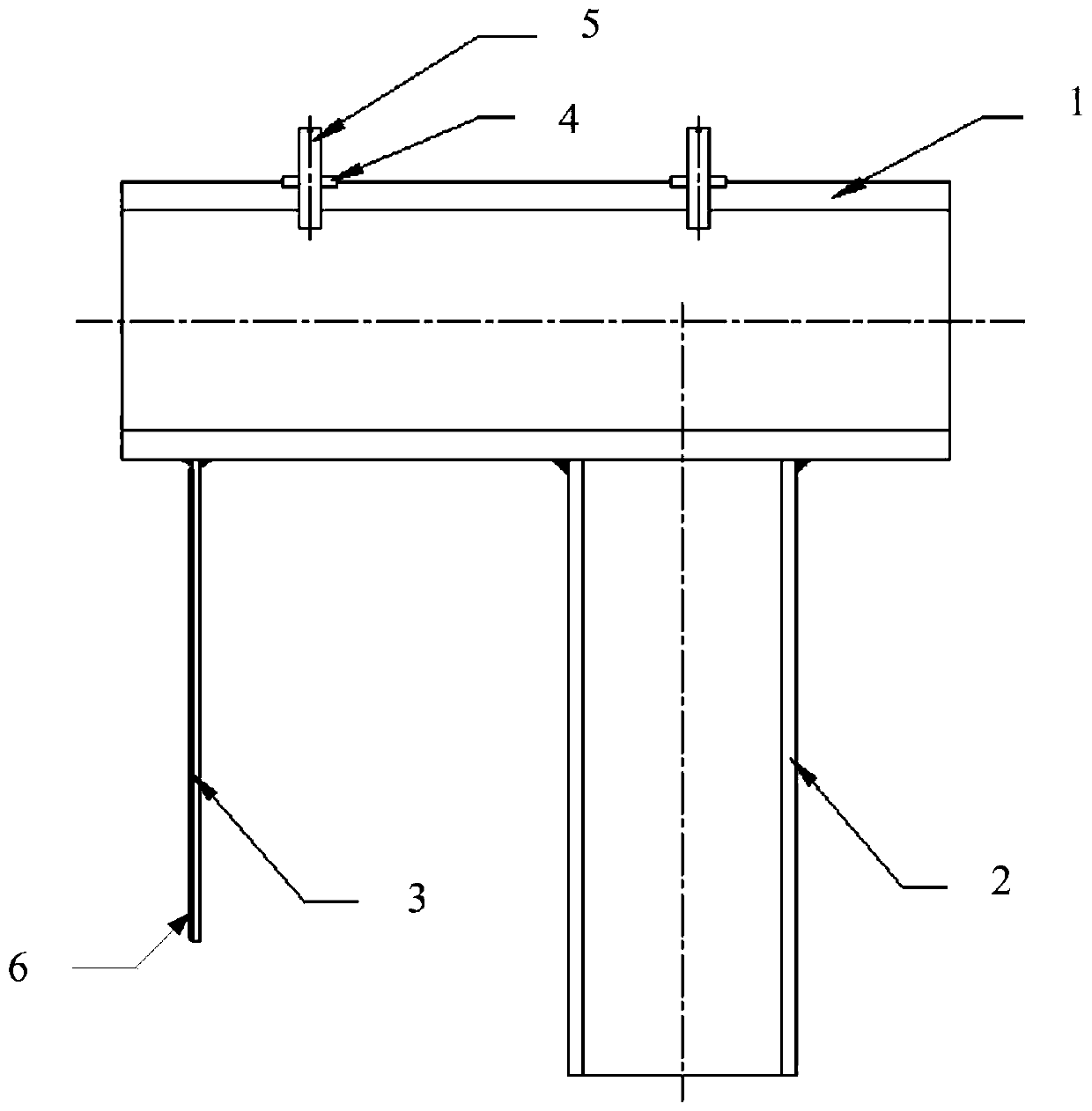

Method for measuring sediment concentration through density of muddy water

InactiveCN103512829ALittle effect of water temperatureAvoid filter effectsSpecific gravity measurementHydrologySolid particle

The invention relates to a method for measuring sediment concentration through density of muddy water. The method comprises the following steps: 1) preparing, namely (1) weighing mass of sediment MS which serves as a sand sample, putting the sediment into a container, measuring volume VW of clear water, pouring the clear water into the container, and stirring to form muddy water; (2) measuring volume V of the muddy water obtained in the step (1), and calculating volume VS of the sediment in the muddy water according to a formula of VS=V-VW; and (3) calculating density of the sediment according to a formula of rhos=Ms / Vs; and 2) testing, namely (1) weighing mass M of muddy water to be measured, and measuring volume V of the muddy water to be measured; (2) calculating density of the muddy water according to a formula of rho=M / V and calculating density of the clear water according to a formula of rhoW=MWVW; and (3) calculating to obtain the volume concentration of the sediment according to a formula of CV=(rho-rhoW)(rhoS-rhoW). The method can be applied to sediment concentration measurement in muddy water rivers, hydropower stations, water pumping stations and the like, sediment concentration measurement in simulation test devices and calibration of various concentration measurement instruments in pressure flow and open-channel flow, as well as solid particle concentration measurement for all solid-liquid two-phase flows comprising solid particles.

Owner:CHINA INST OF WATER RESOURCES & HYDROPOWER RES +1

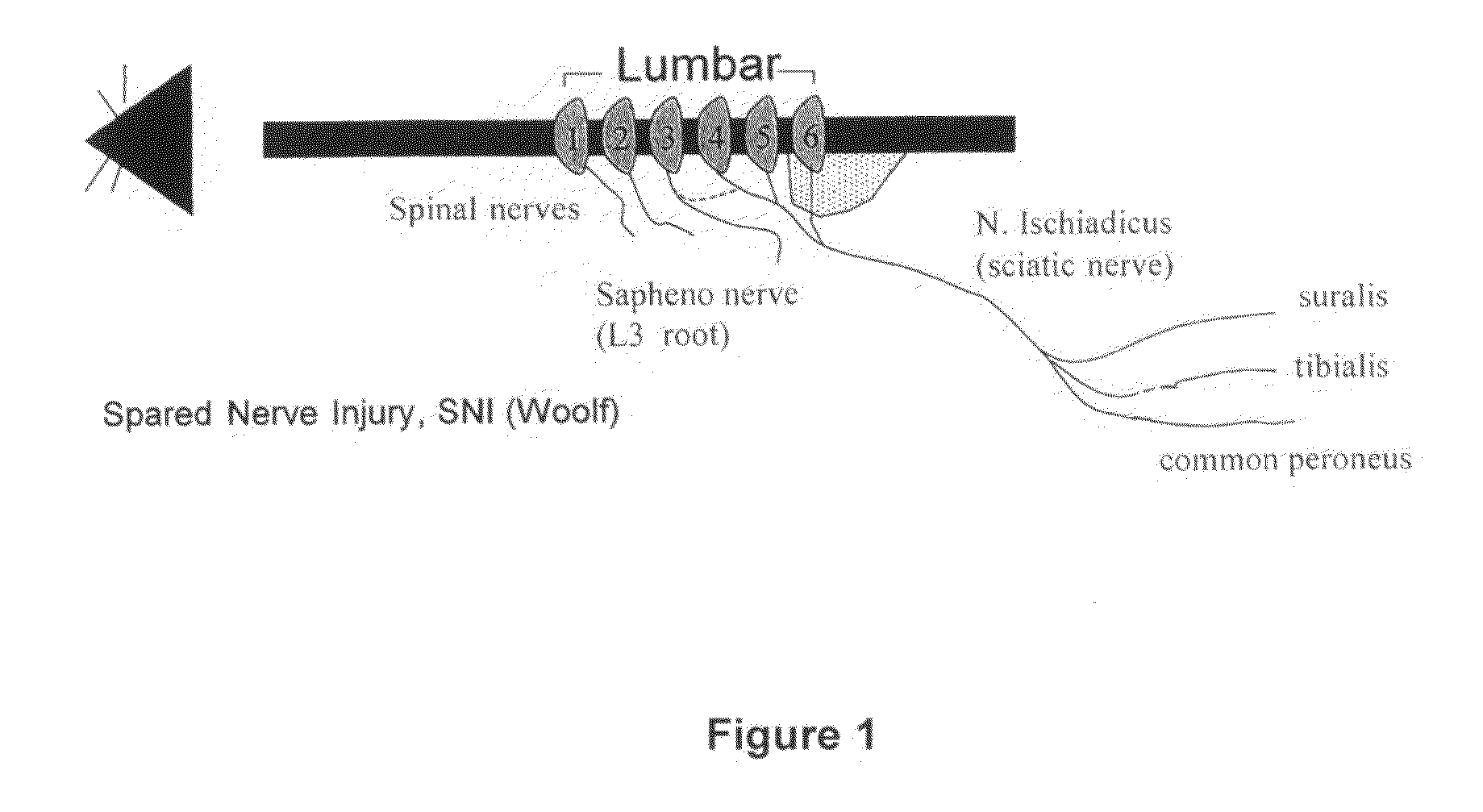

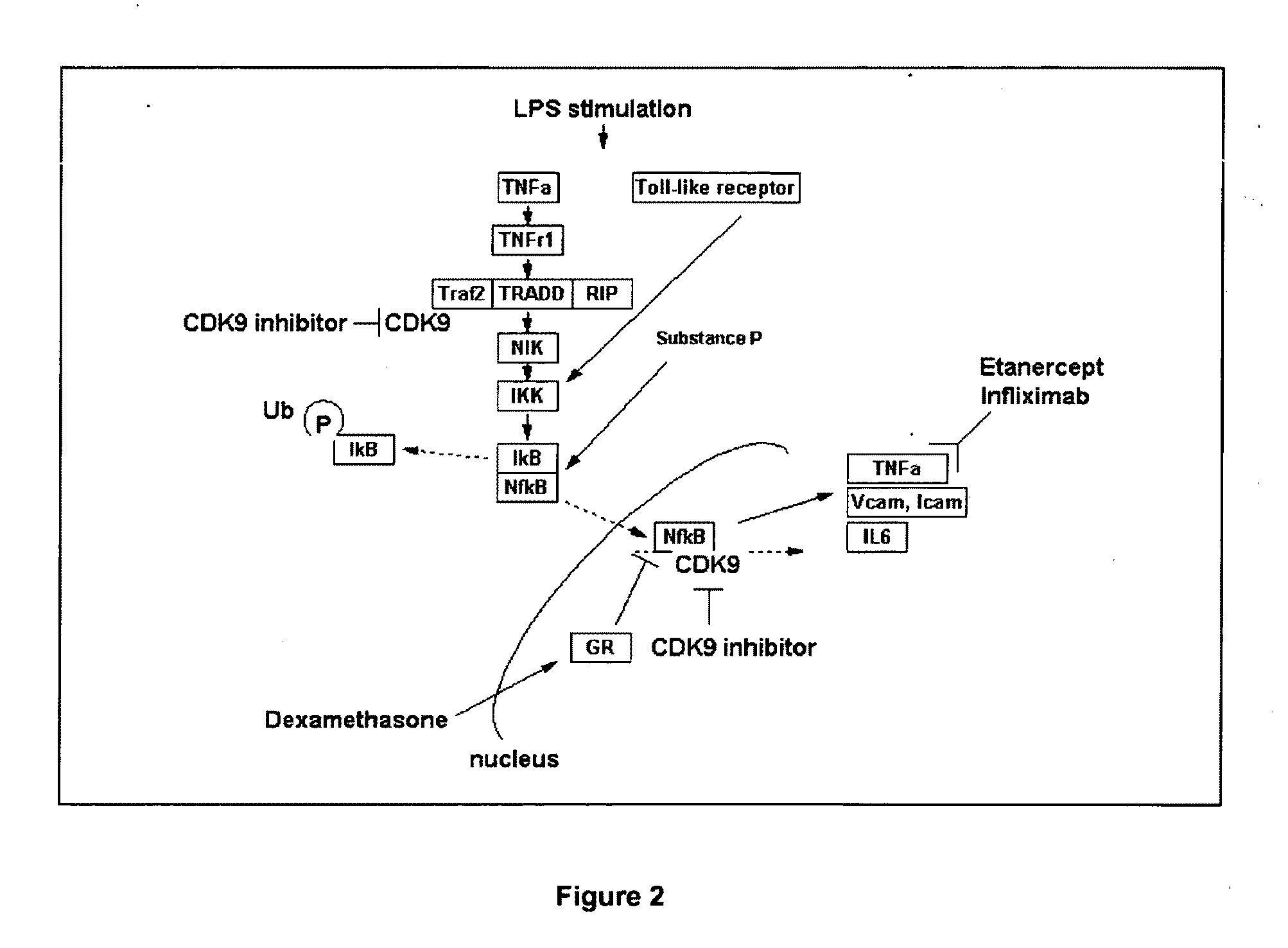

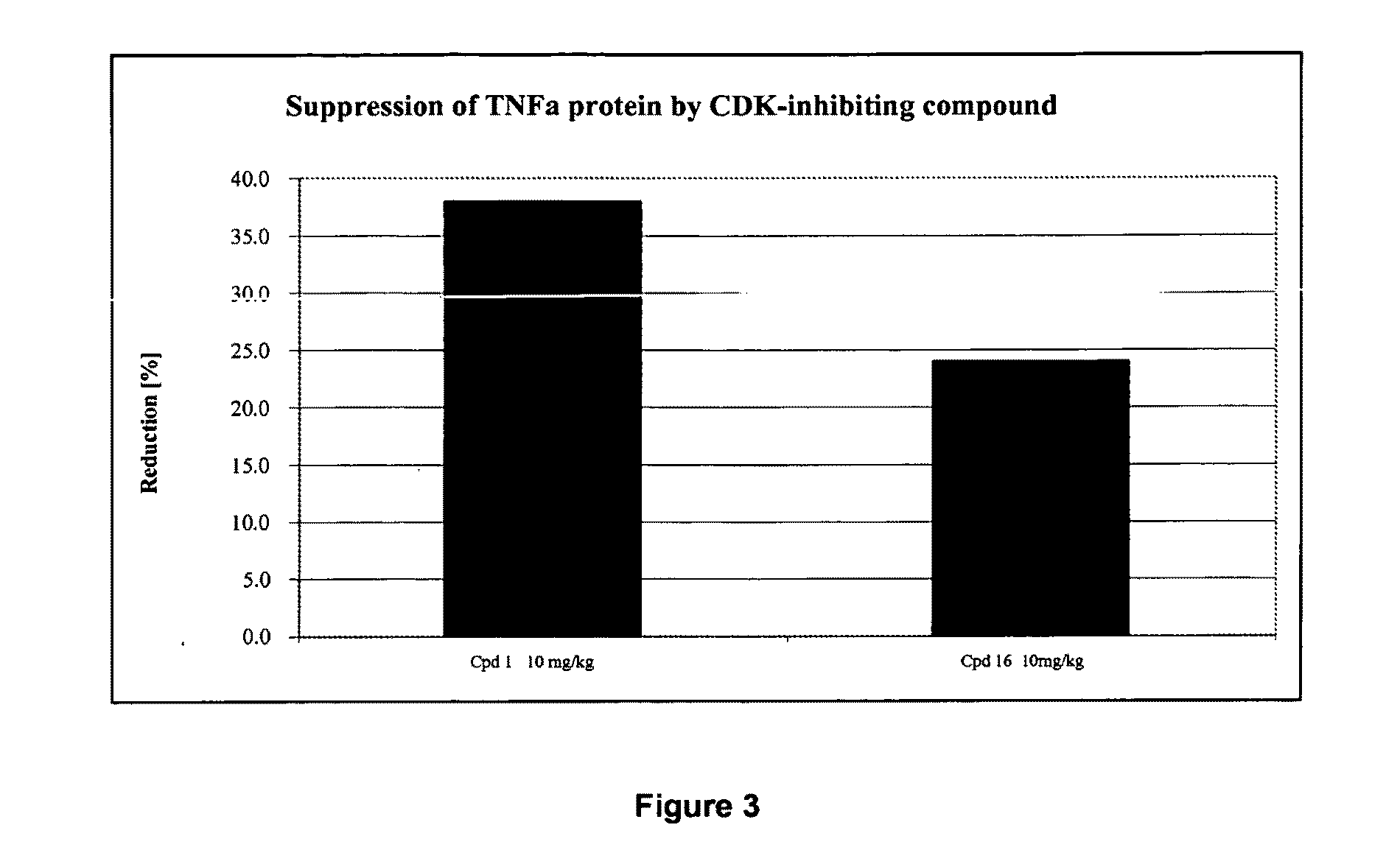

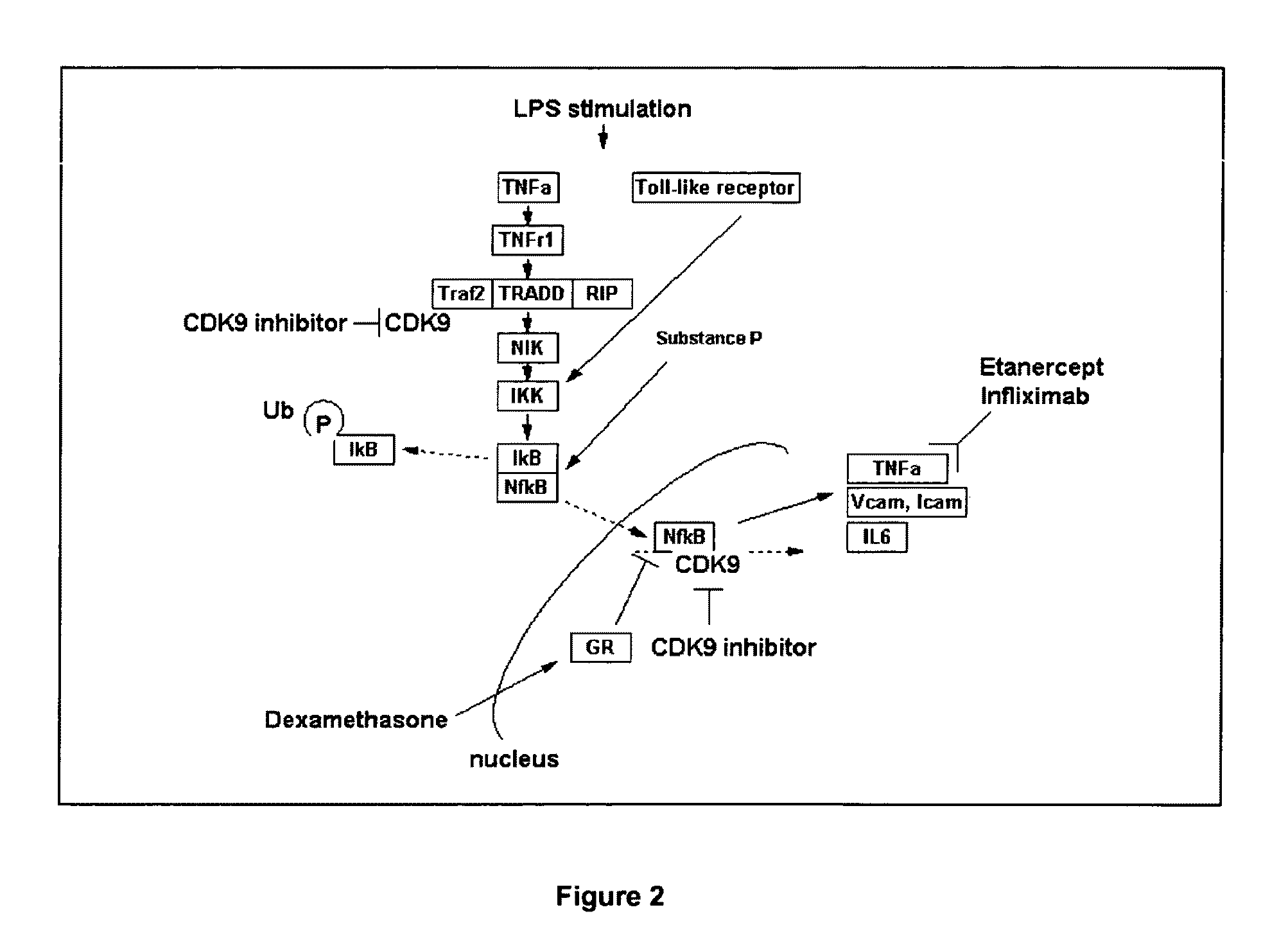

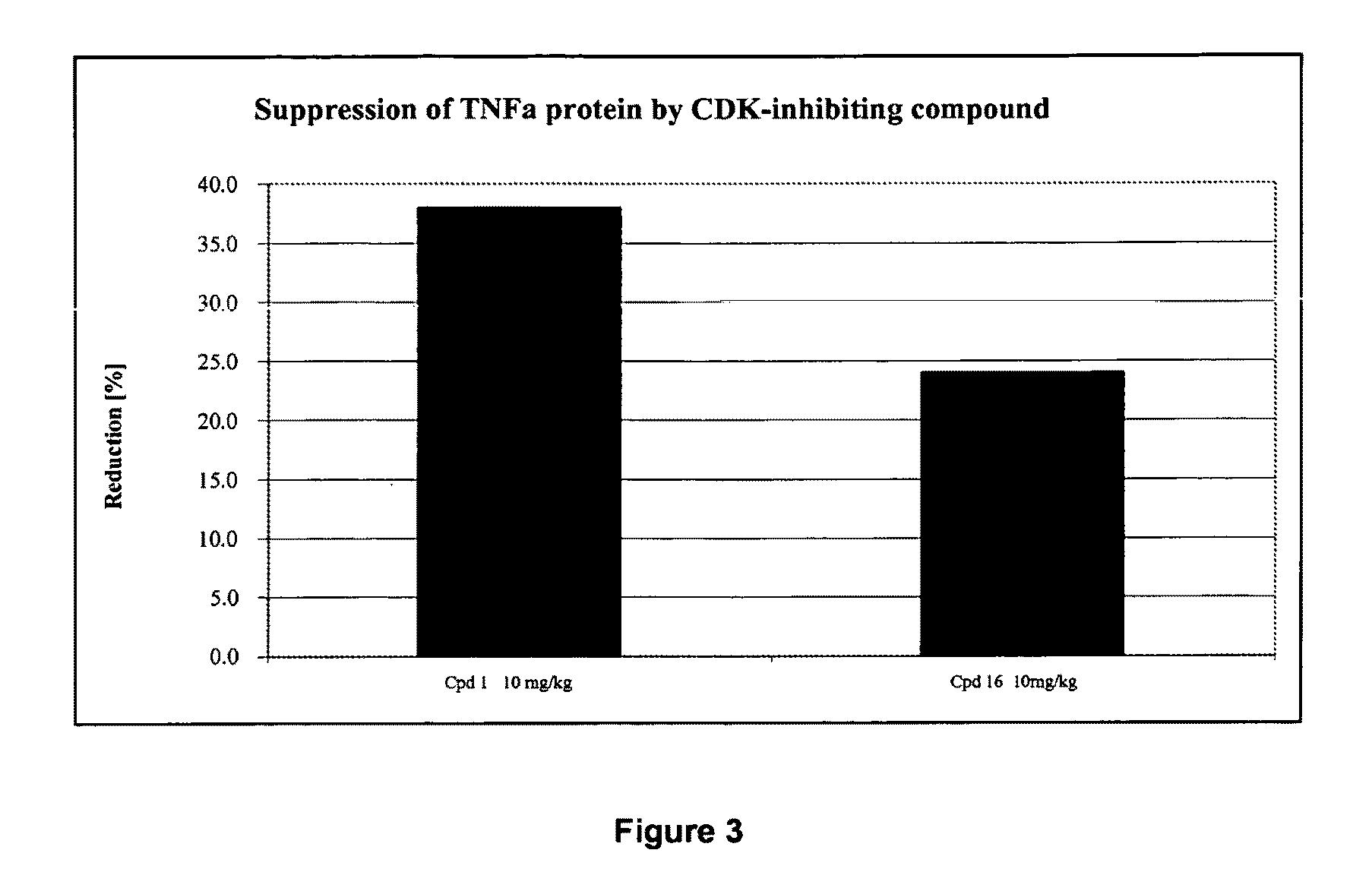

Inhibitors of Protein Kinases

InactiveUS20100249149A1Improve flow characteristicsUniform and stable flowOrganic active ingredientsBiocideCyclinBiochemistry

Owner:ASTRAZENECA AB

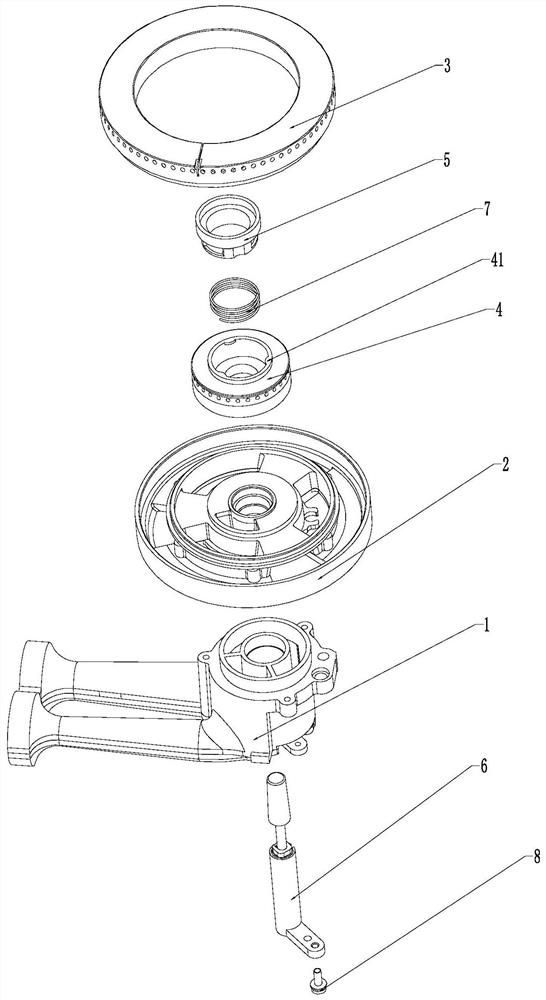

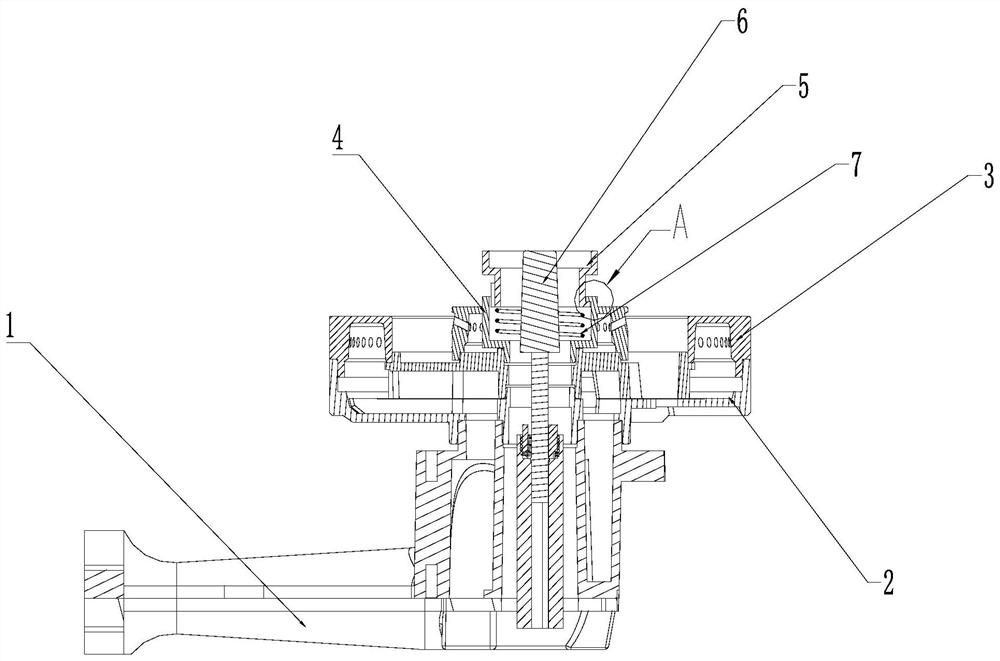

Air-conditioner wind deflector protecting method and device

ActiveCN104075414AAvoid bakingSolve the fragileMechanical apparatusSpace heating and ventilation safety systemsEngineering

Owner:GREE ELECTRIC APPLIANCES INC

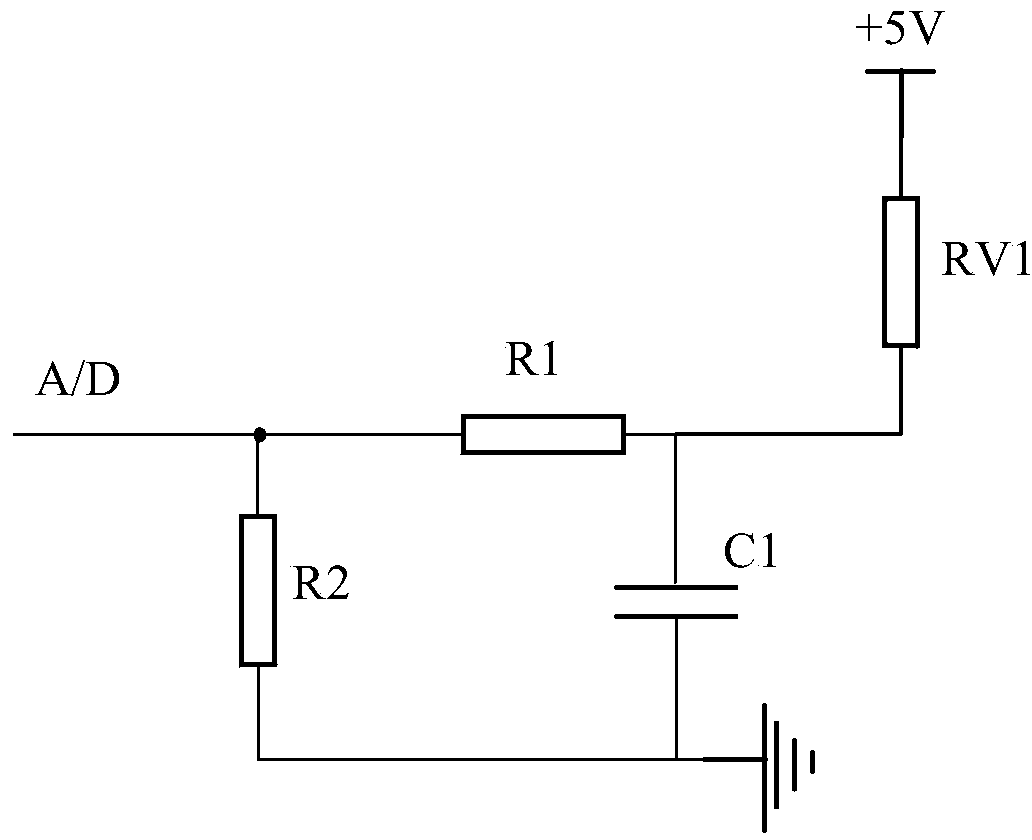

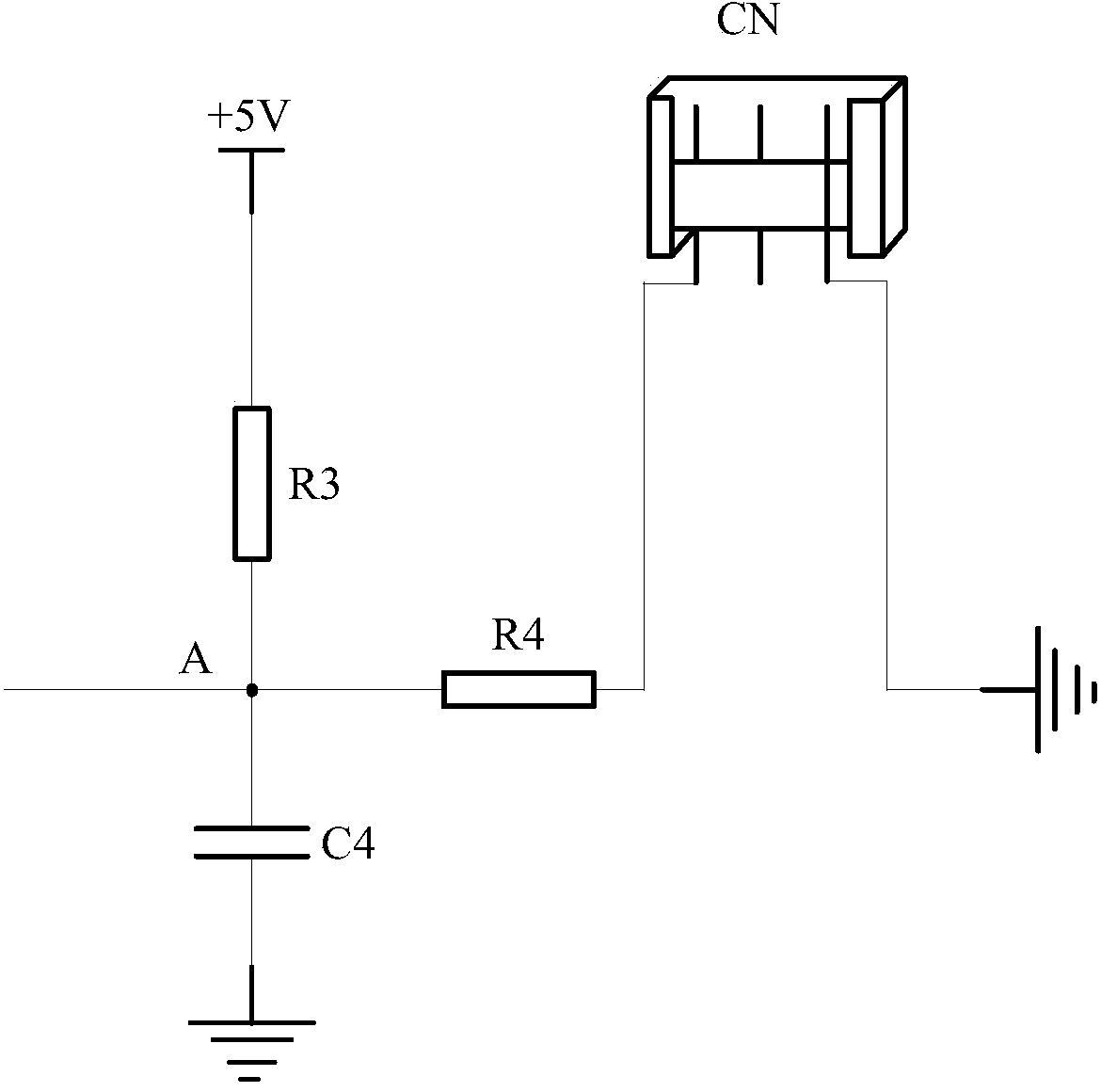

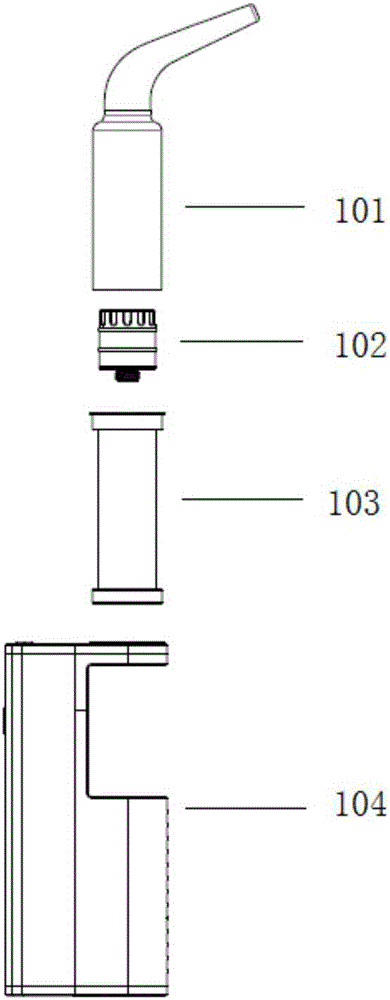

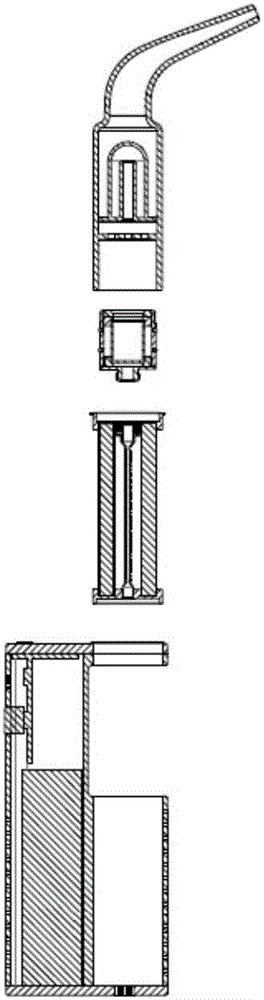

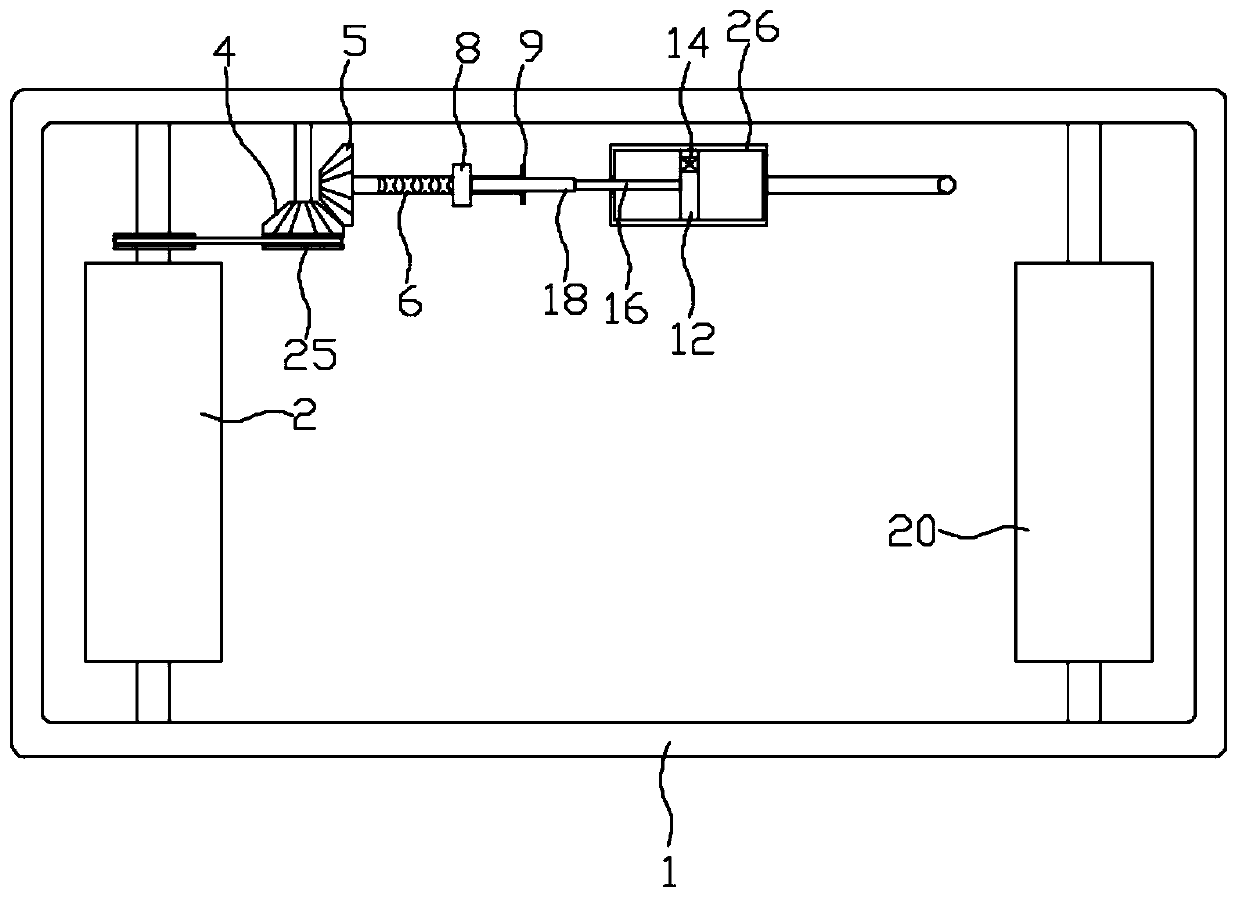

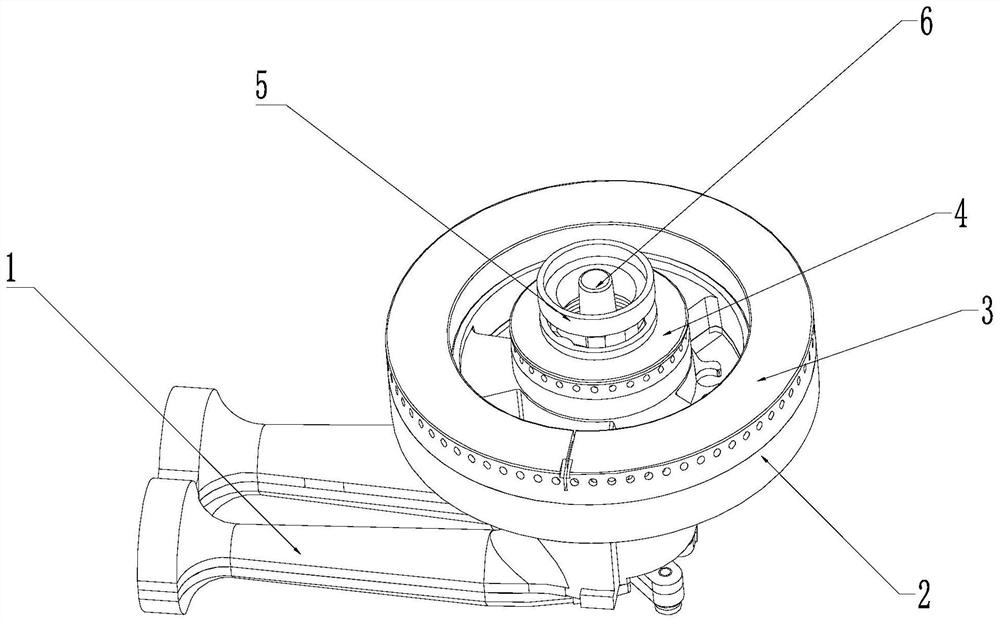

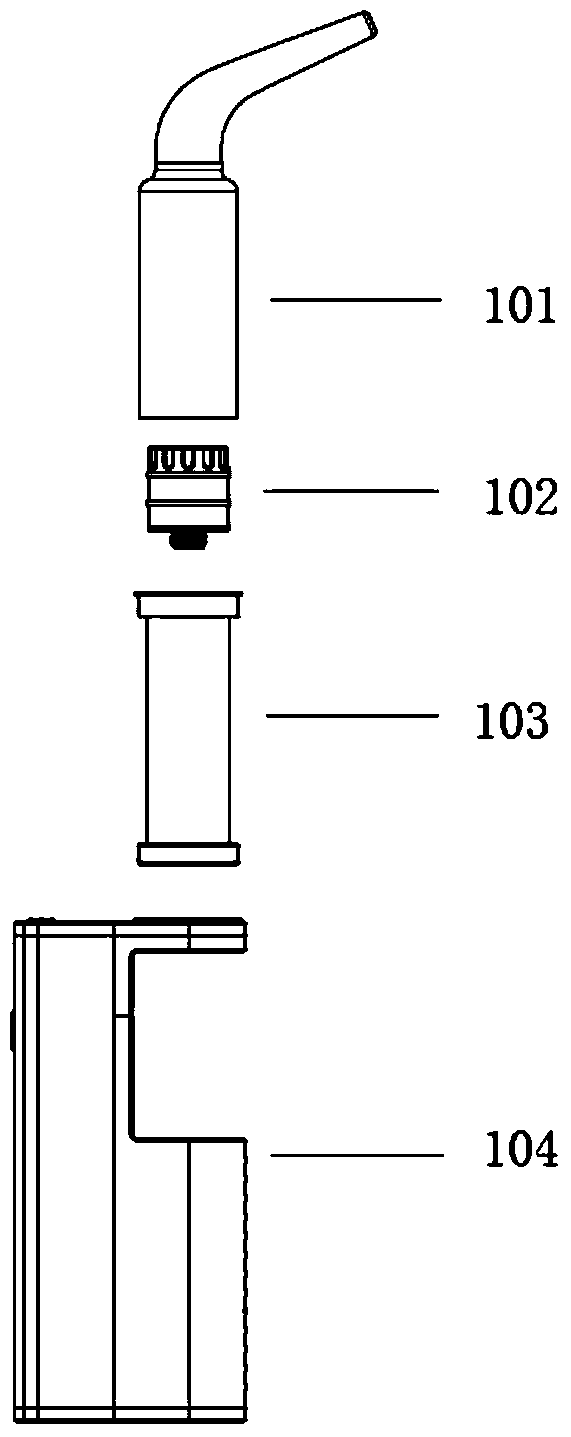

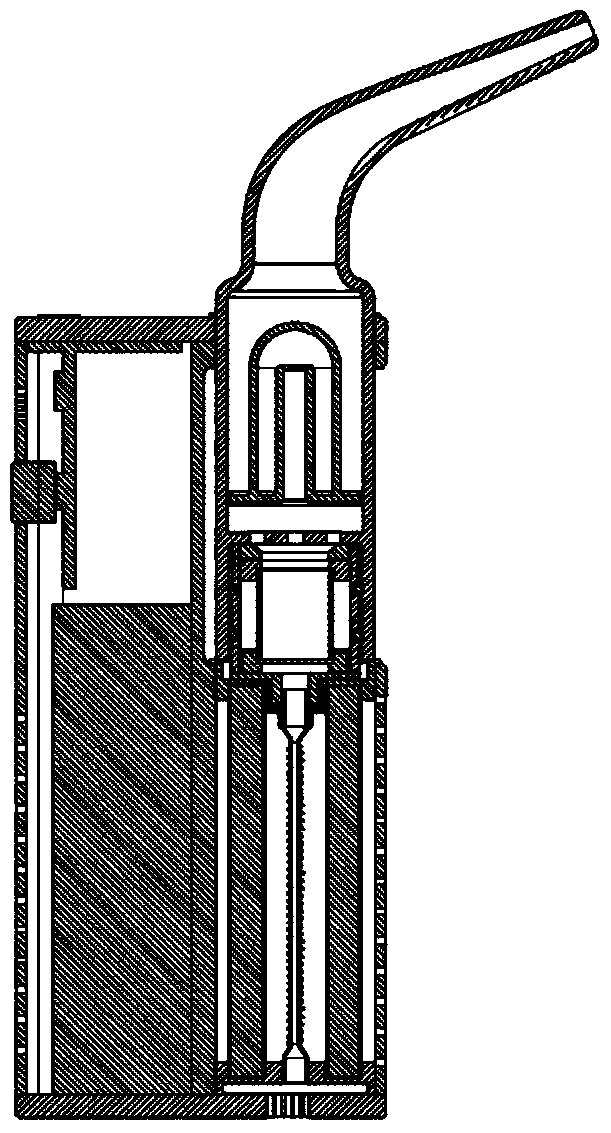

Airflow heating type electronic cigarette

The invention discloses an airflow heating type electronic cigarette. The electronic cigarette can comprise a filtering assembly, a tobacco pot assembly, a heating assembly and a battery assembly. Fluid is placed in the filtering assembly to filter smoke; the tobacco pot assembly is connected to the filtering assembly, and a heated medium is placed in the tobacco pot assembly; the heating assembly is connected to the tobacco pot assembly and used for generating heating airflow to heat the heated medium in the tobacco pot assembly; the battery assembly is connected to the heating assembly to supply power to the heating assembly.

Owner:SHENZHEN YOOTECH CO LTD

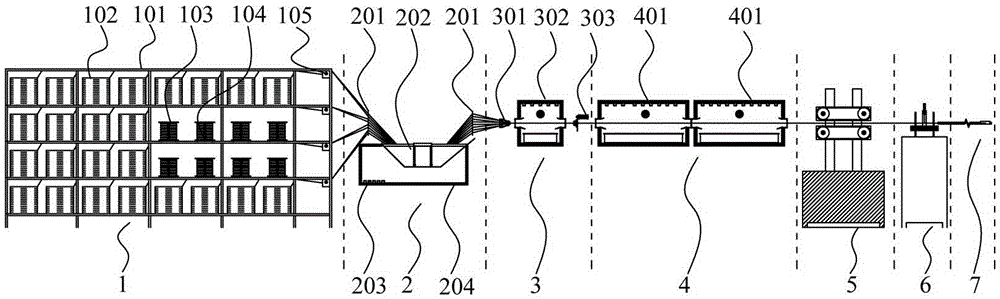

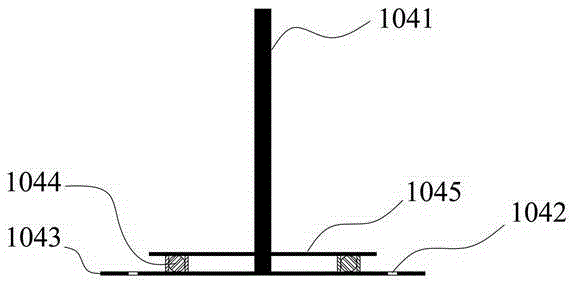

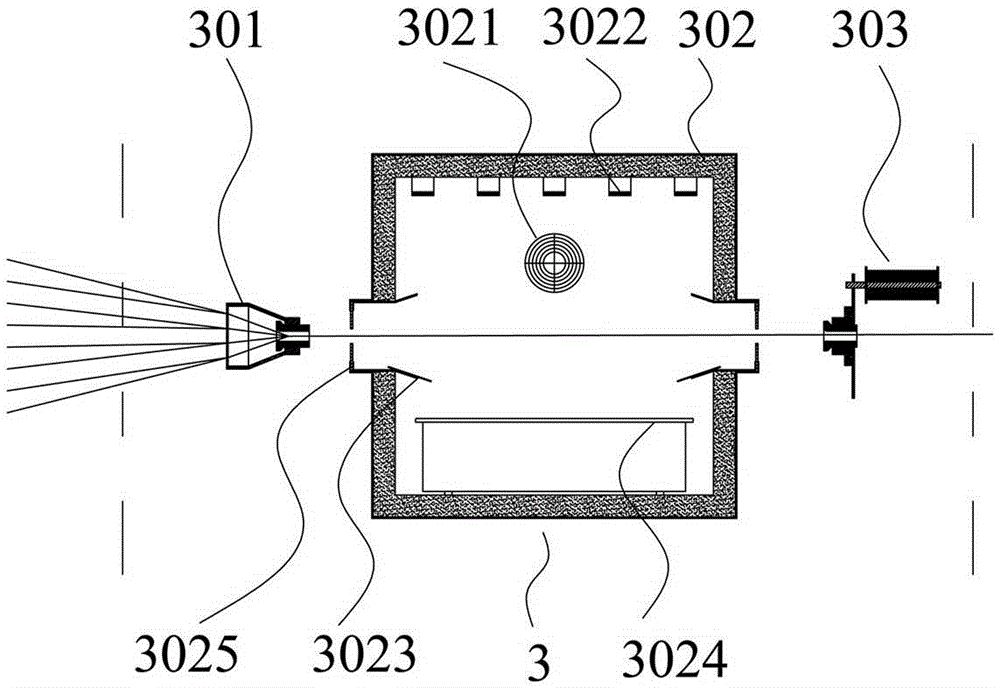

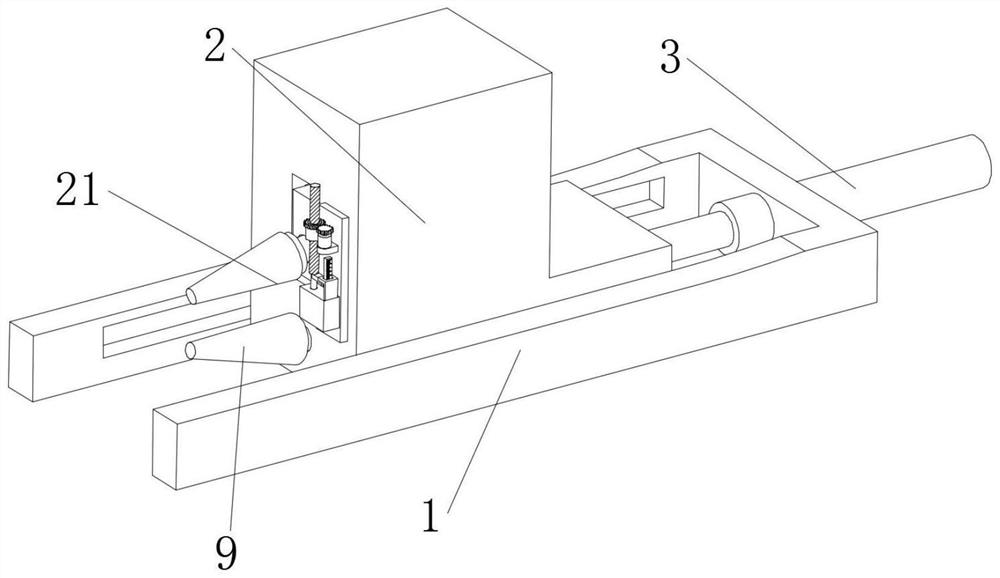

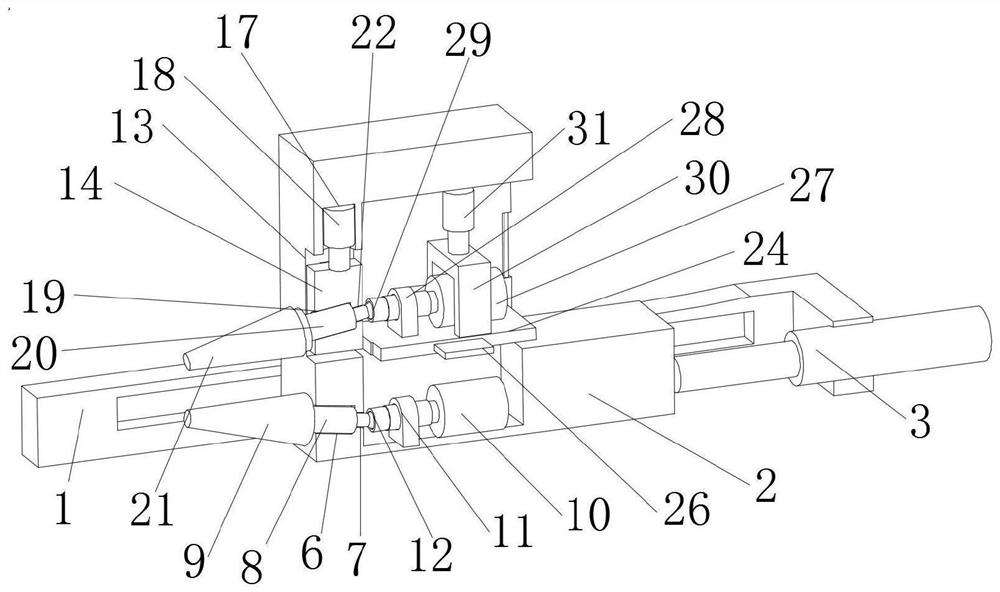

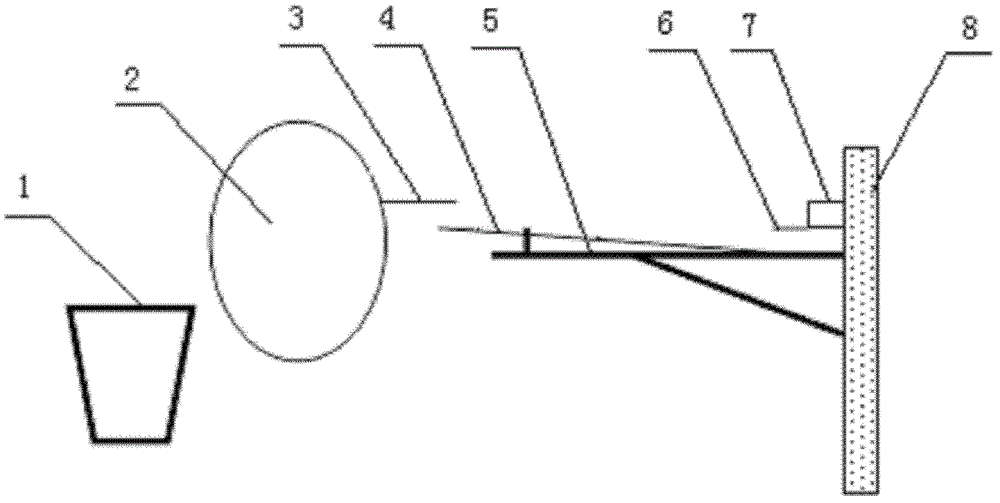

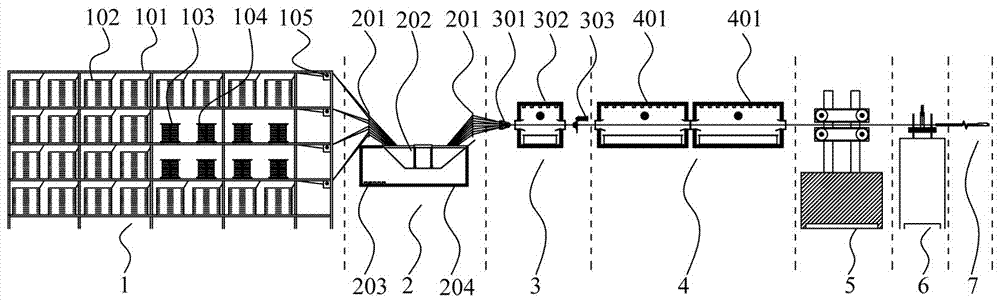

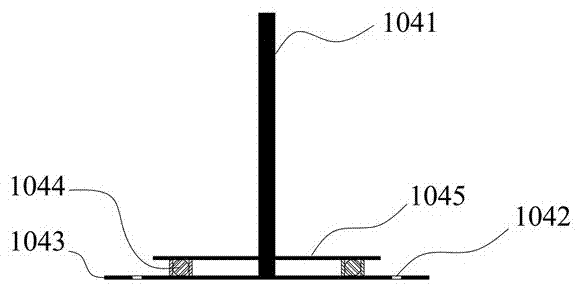

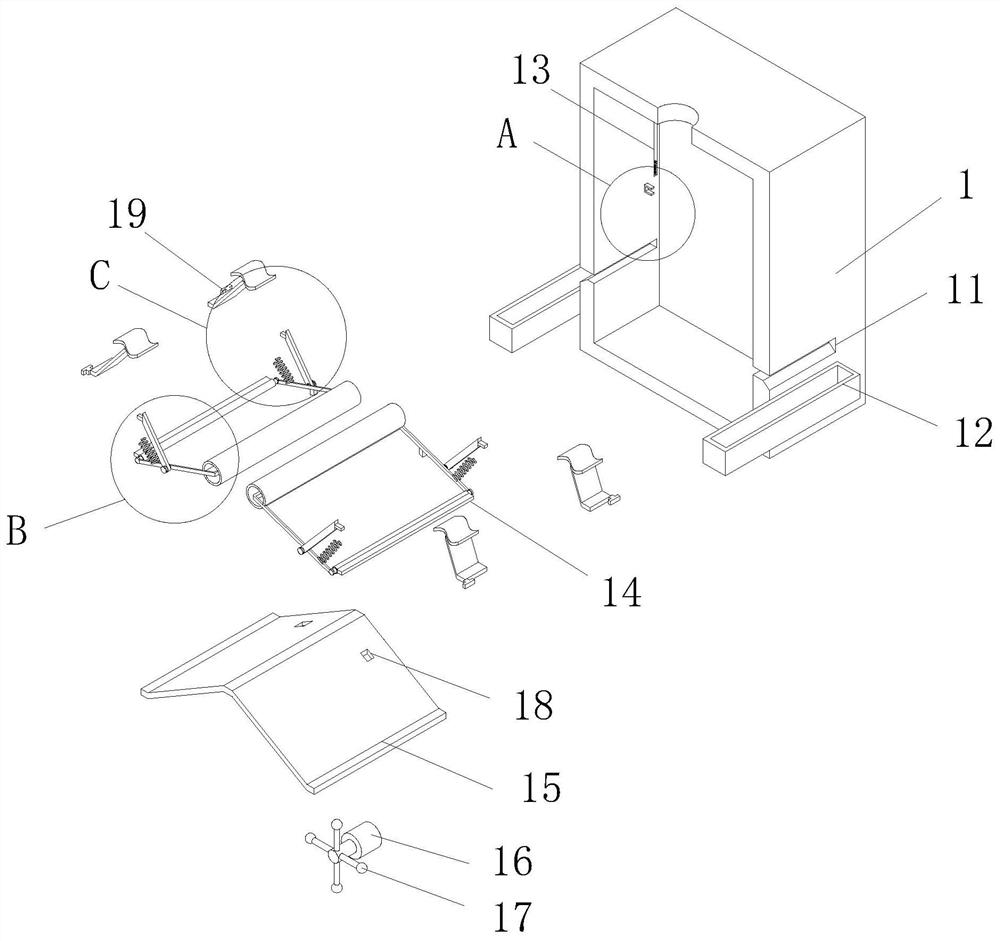

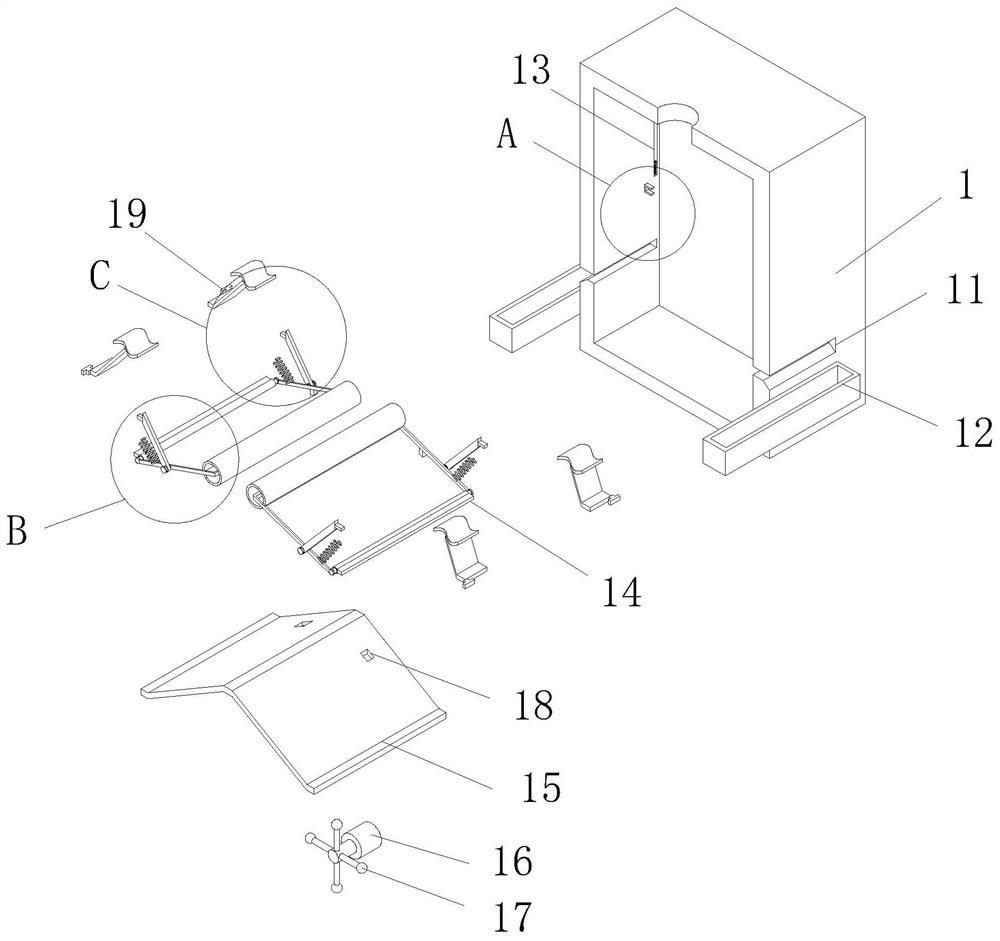

Composite fiber reinforced polymer (FRP) rebar preparation device

The invention provides a composite fiber reinforced polymer (FRP) rebar preparation device which comprises a yarn feeding device, an impregnation device, a forming device, a heating curing device, a traction device, a cutting device and a length control device. Relative to the prior art, the preparation device has substantive characteristics and progress, particularly, yarn pressing rolling shafts and yarn threading holes are arranged in the yarn feeding device of the composite FRP rebar preparation device, so that fiber bundles are enabled to be in a tension state, and different fiber bundles are prevented from knotting and rubbing; through the adoption of the impregnation device, the fiber bundles are fully and uniformly impregnated, the coating amount is small, the fiber content of a composite FRP rebar is increased, and the standard deviation of the mechanical performance of the composite FRP rebar is reduced; through the adoption of the forming device, the distribution uniformity of the fiber bundles in thermosetting resin is greatly improved; through the adoption of the heating curing device, the curing temperature is enabled to be stable, and the production is facilitated; and through the adoption of a buzzer of the length control device, operators can be reminded to carry out cutting, the FRP rebar is prevented from being over-roasted, and the continuity and safety of production are improved.

Owner:ZHENGZHOU UNIV

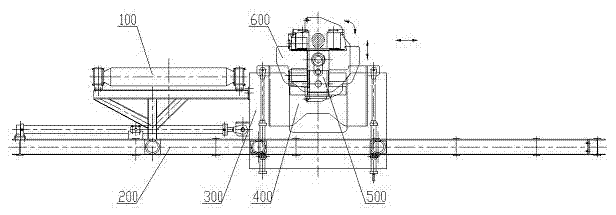

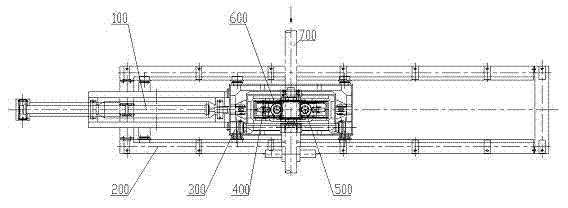

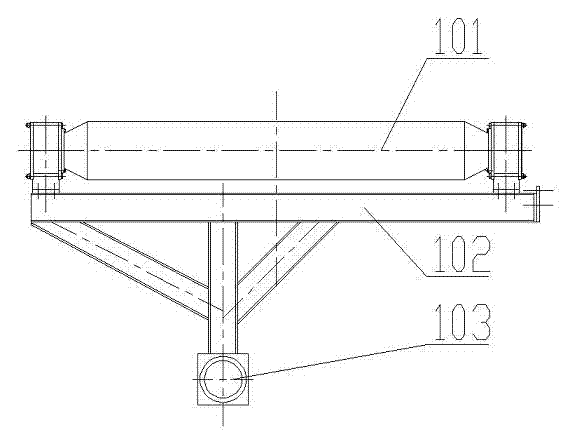

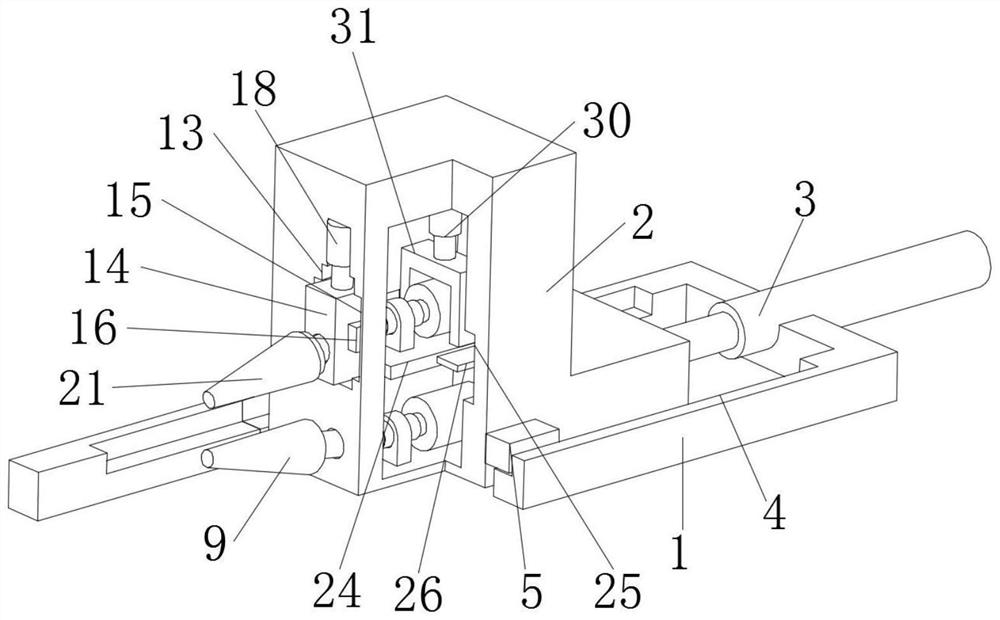

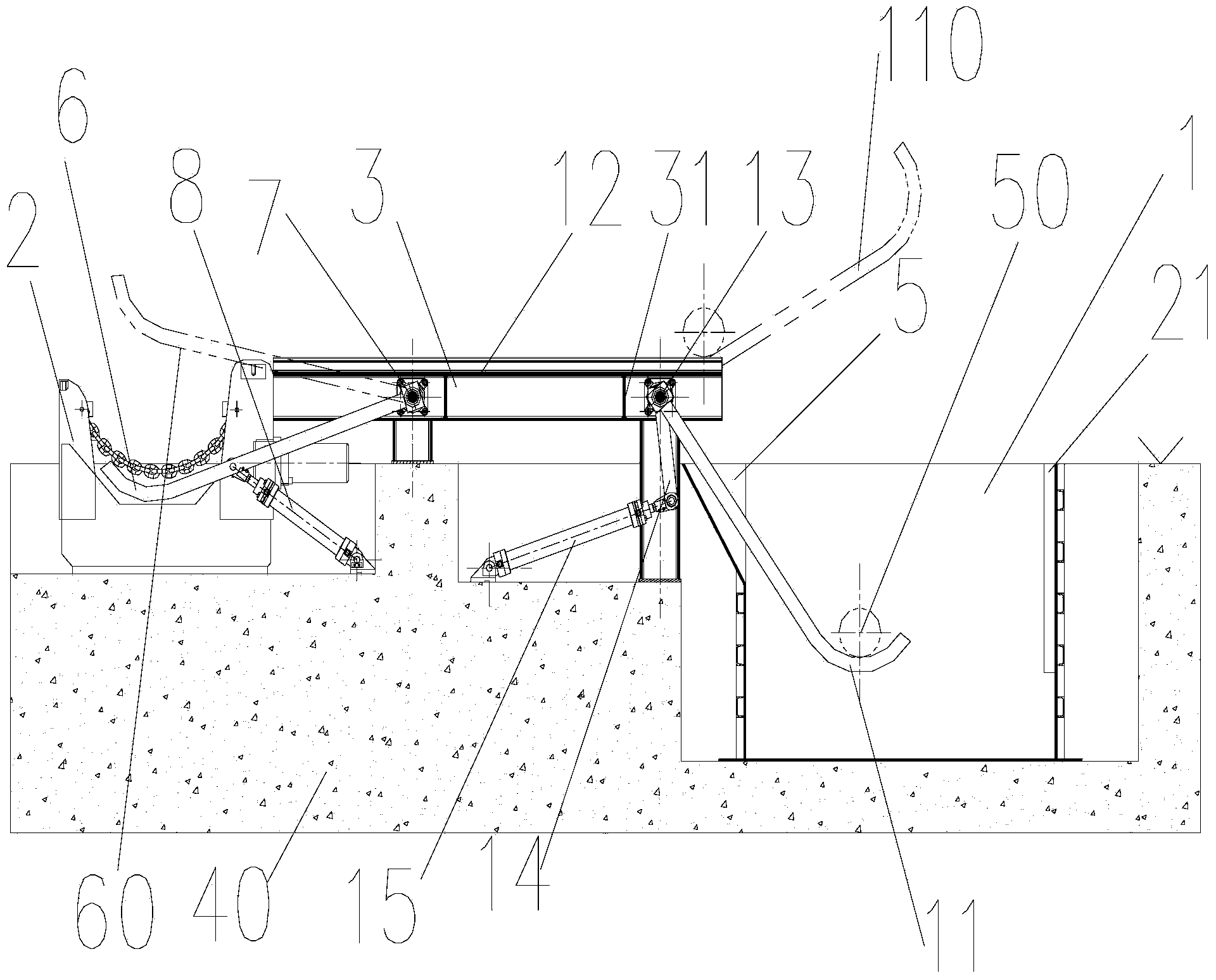

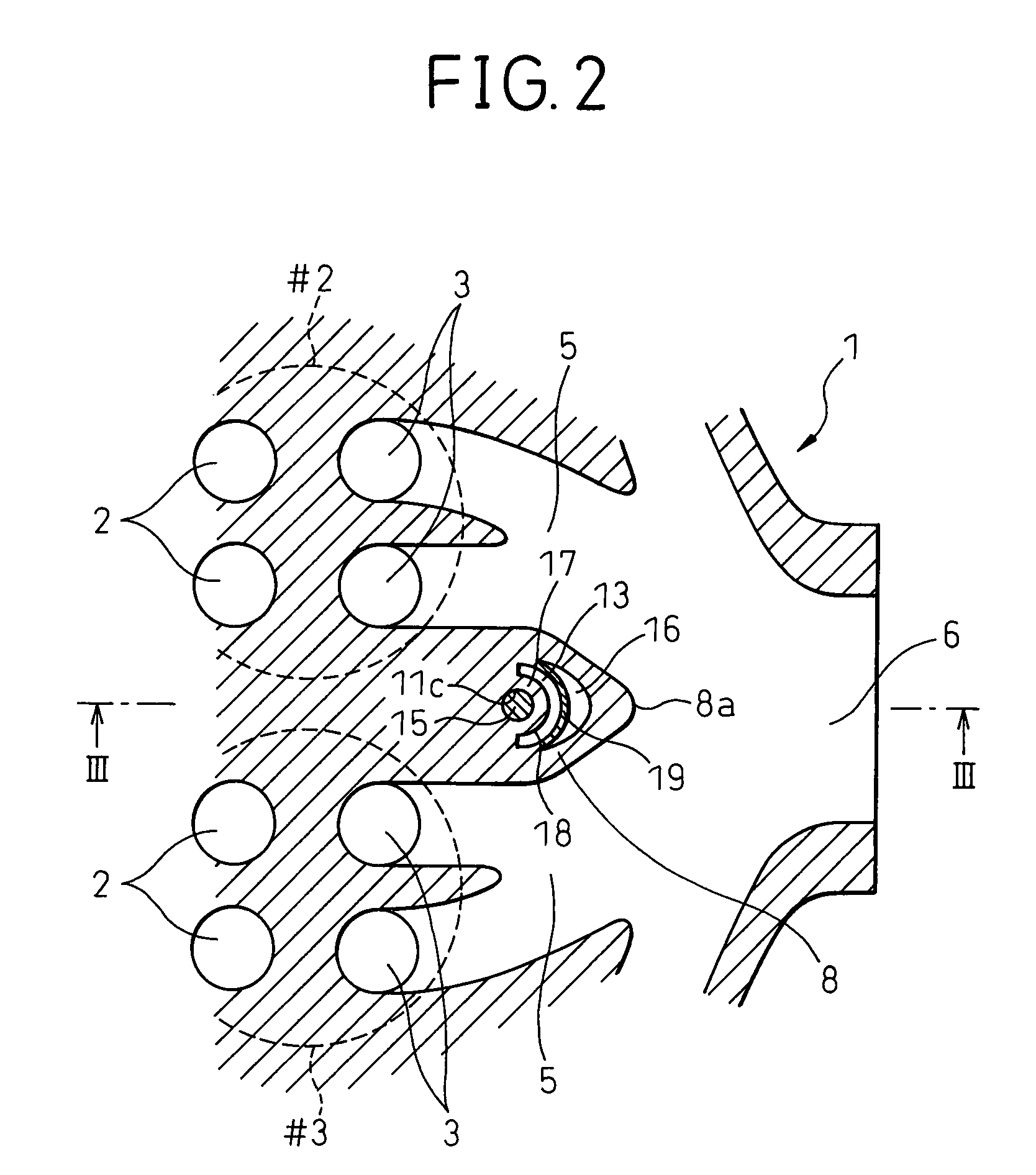

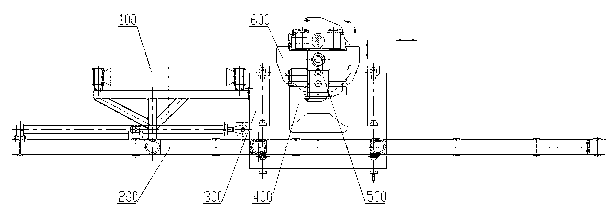

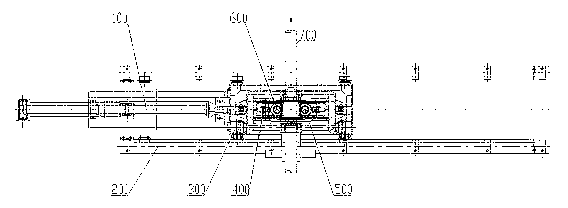

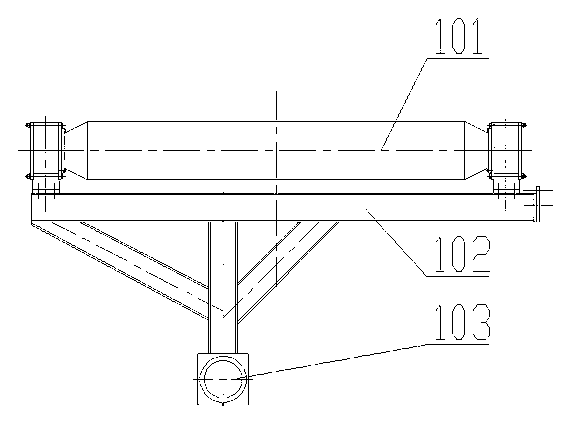

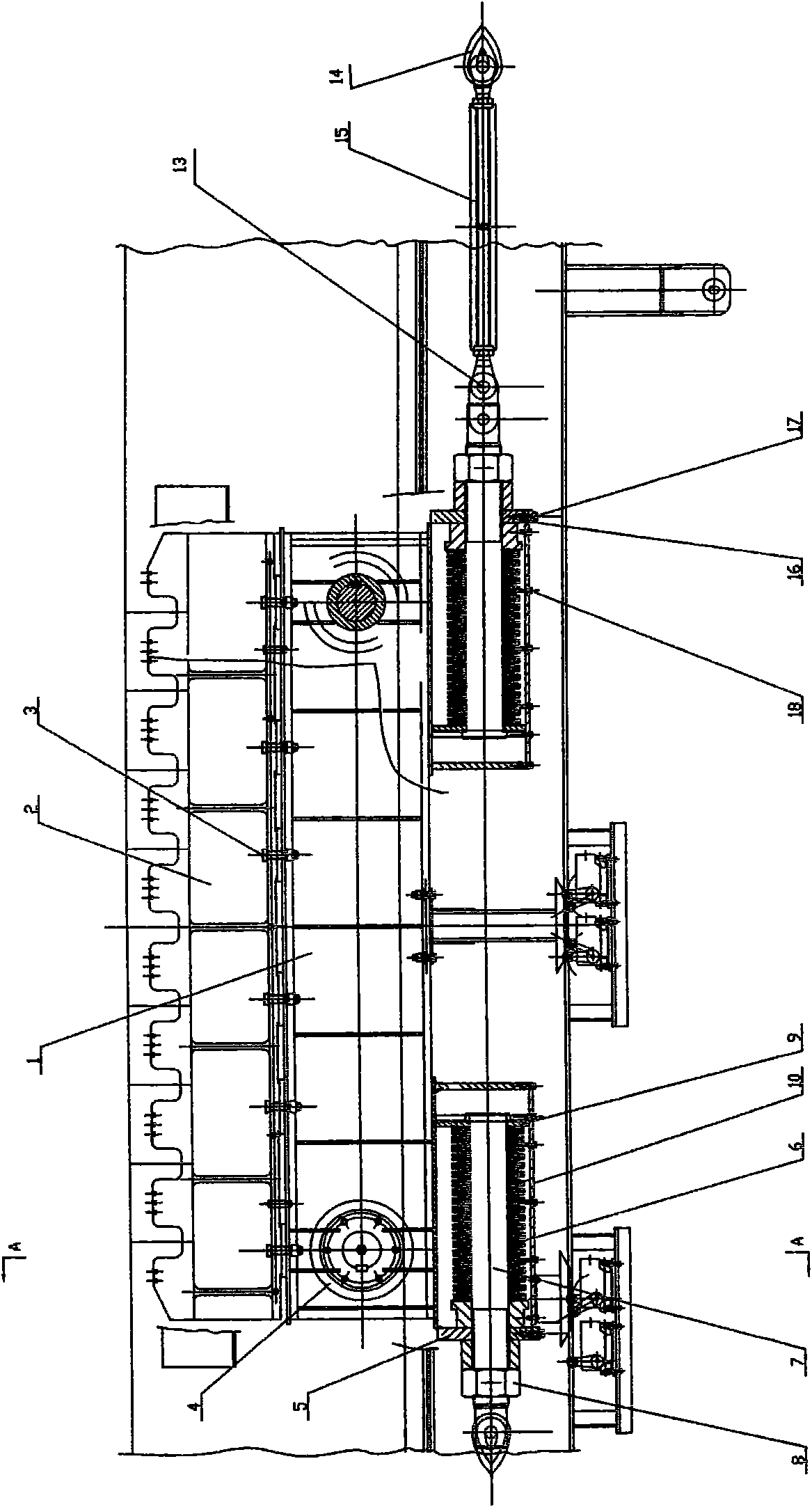

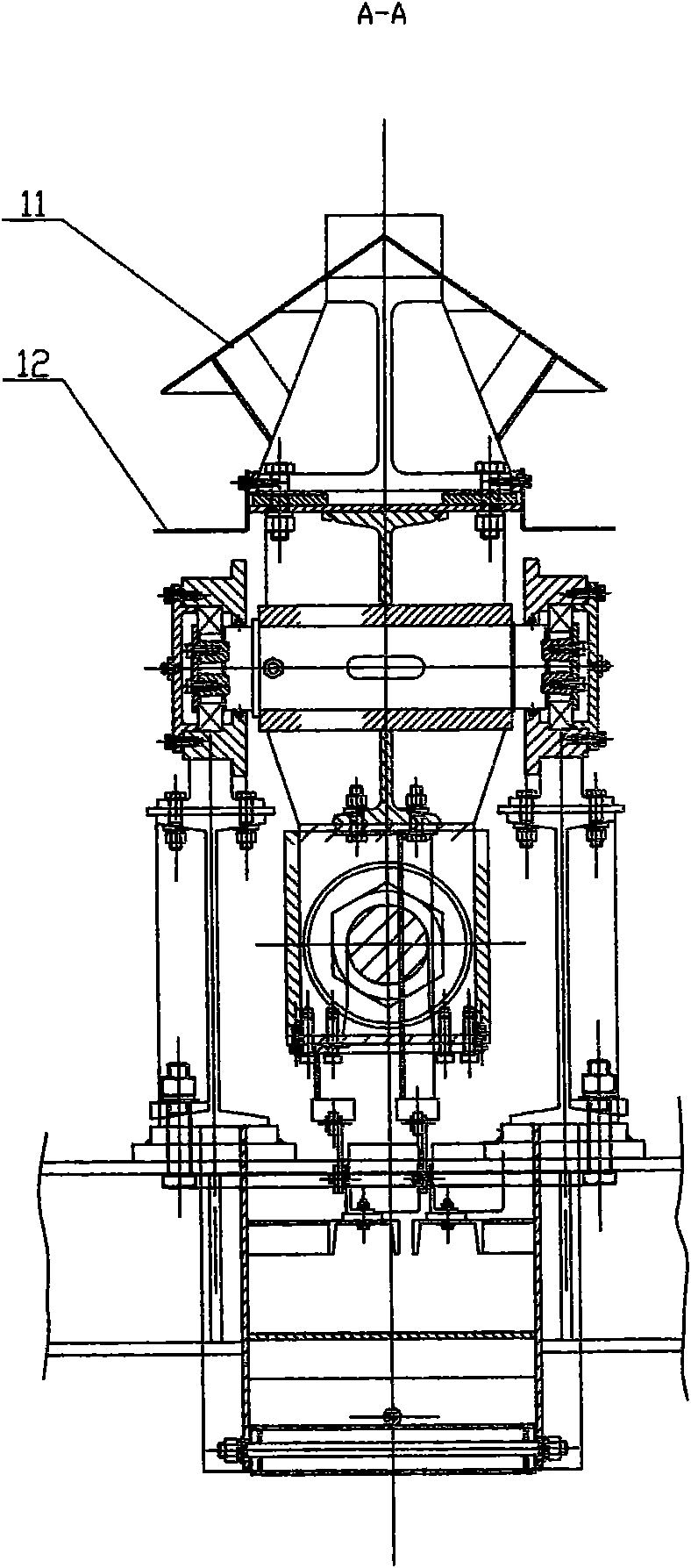

Front steel turning device of cogging mill

ActiveCN102310095AHigh positioning accuracyMeet the requirements of rolling processWork manipulationAutomatic controlEngineering

The invention relates to a front steel turning device of a cogging mill, which comprises an alternative roller (100), a base (200), a translation framework (300), a lifting mechanism (400), a turning mechanism (500), and a clamping roller mechanism (600). The alternative roller (100) is fixedly connected with the translation framework (300) and can move linearly along the base (200), the lifting mechanism (400) is arranged in the translation framework (300), the turning mechanism (500) is arranged on the side face of the lifting mechanism (400), the turning mechanism (500) and the lifting mechanism (400) can simultaneously move up and down along the inner side of the translation framework (300), the clamping roller mechanism (600) is connected with the output shaft of the turning mechanism (500) to realize synchronous rotation along with the turning mechanism (500), the translation framework (300), the lifting mechanism (400) and the clamping roller mechanism (600) are provided with adisplacement sensor, and the turning mechanism (500) is provided with an encoder. Automatic control of the whole steel turning process can be achieved, the positioning accuracy is high, and the device can be used conveniently and reliably, has a simple structure and low cost and can be maintained conveniently.

Owner:HUATIAN ENG & TECH CORP MCC

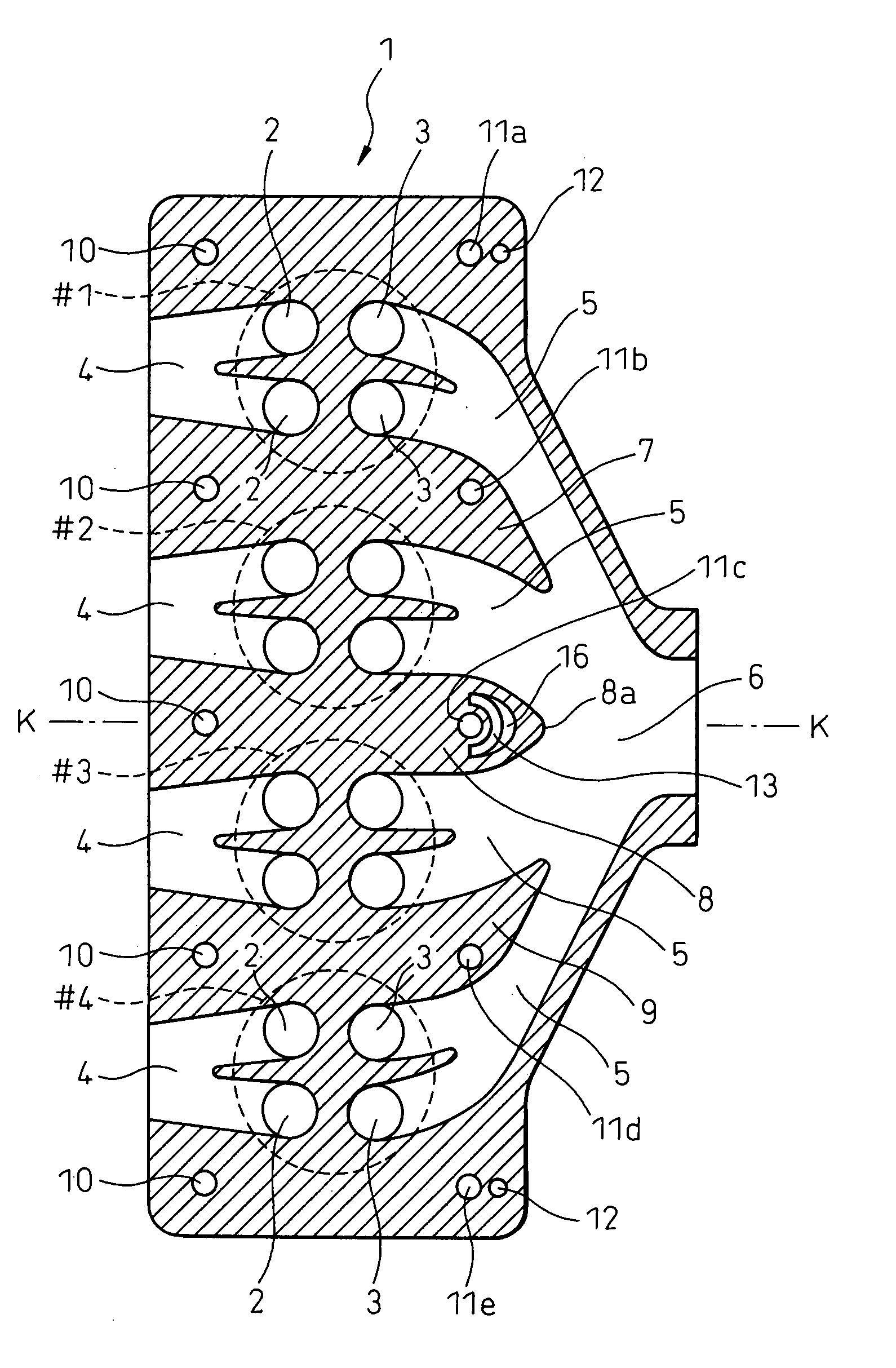

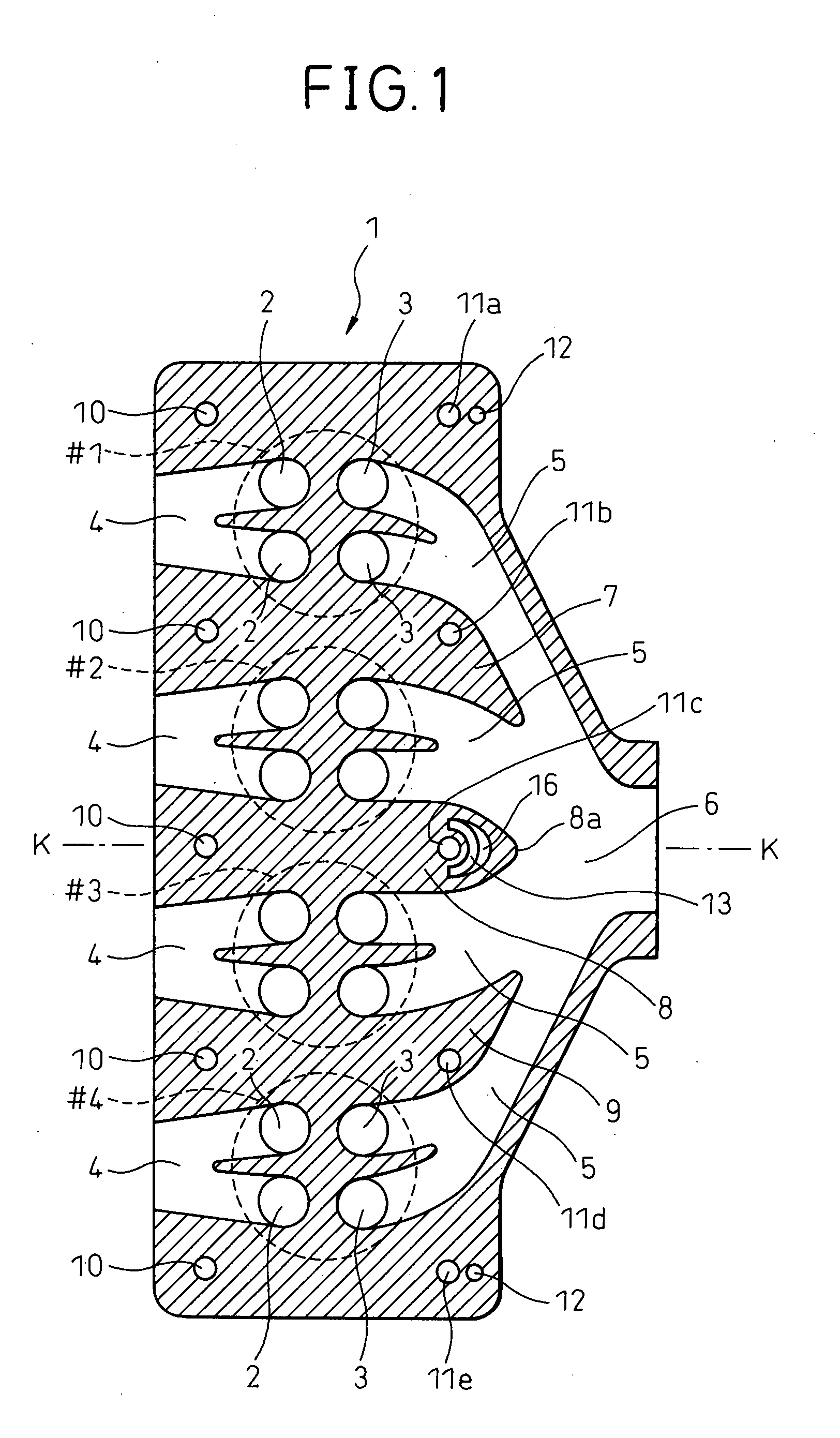

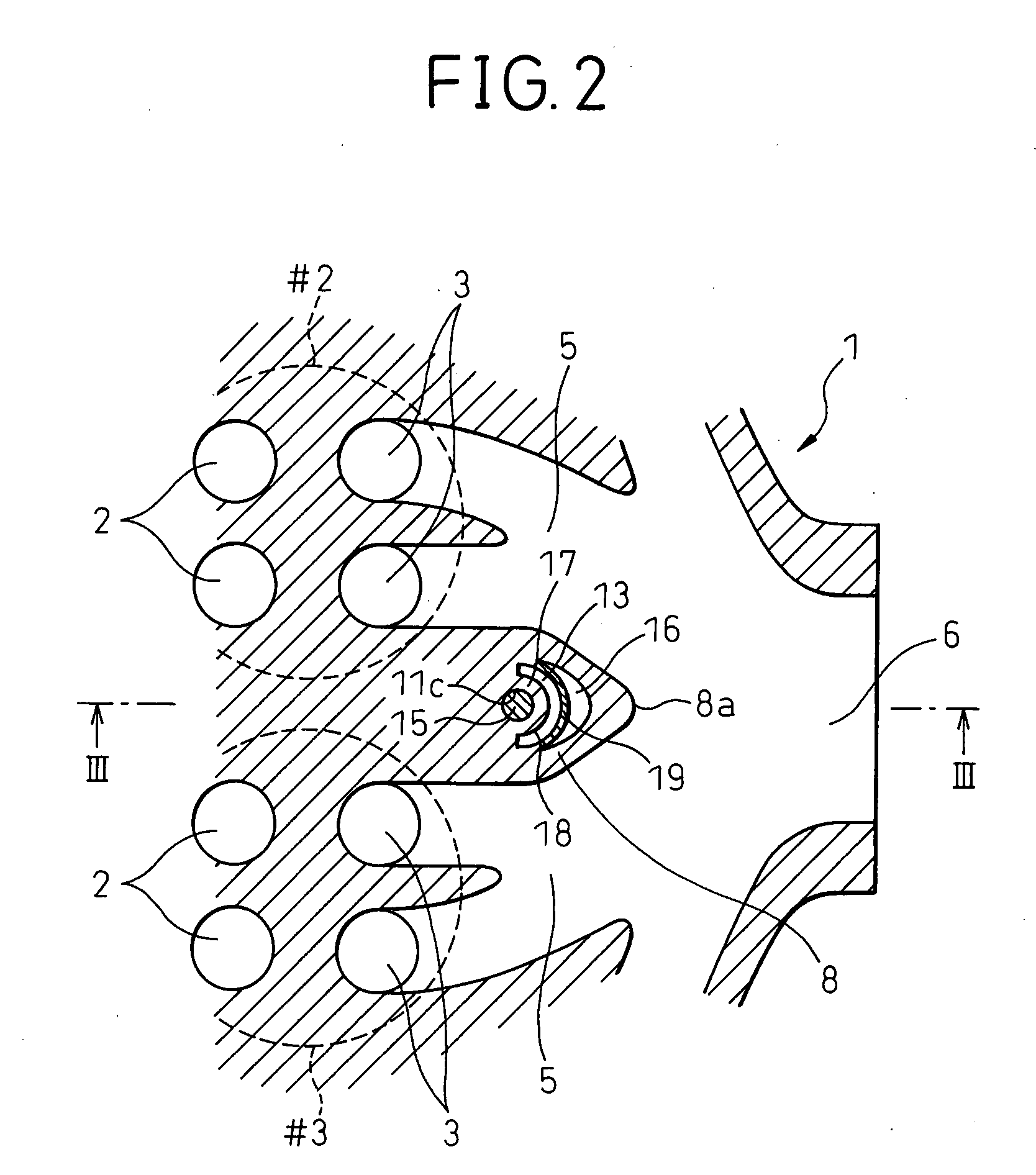

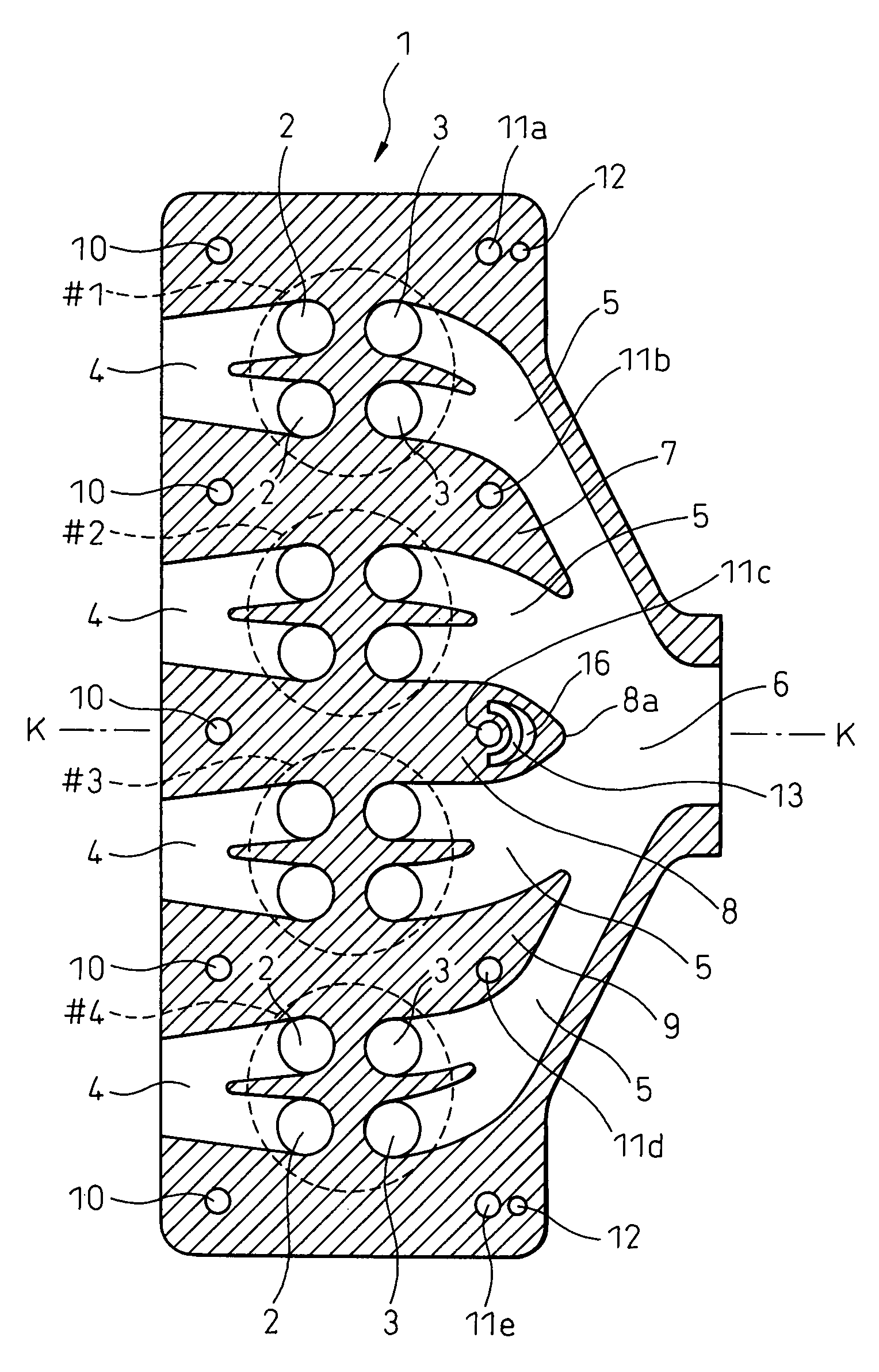

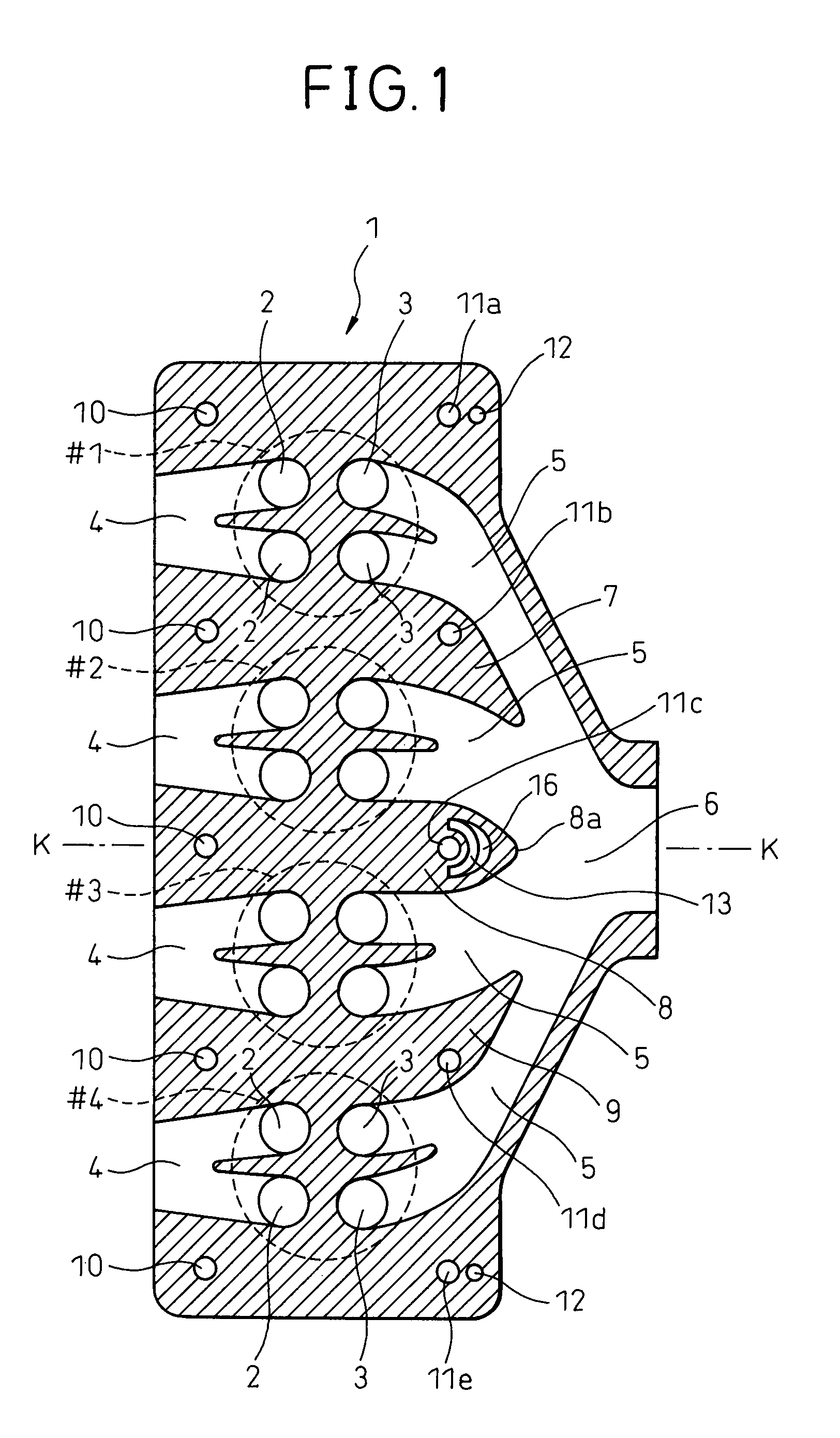

Cylinder head

InactiveUS20080110431A1Increased durabilityAvoid bakingCylinder headsCylindersCylinder headEngineering

A cylinder head in which a partition wall for separating exhaust ports of adjoining cylinders extends from between these adjoining cylinders to an exhaust merging portion and the partition wall is formed with a head bolt insertion hole inside it, an oil passage is formed in the partition wall between the front end of the partition wall facing the exhaust merging portion and the head bolt insertion hole, and a heat insulating layer is formed inside the partition wall between the front end of the partition wall and the oil passage.

Owner:TOYOTA JIDOSHA KK

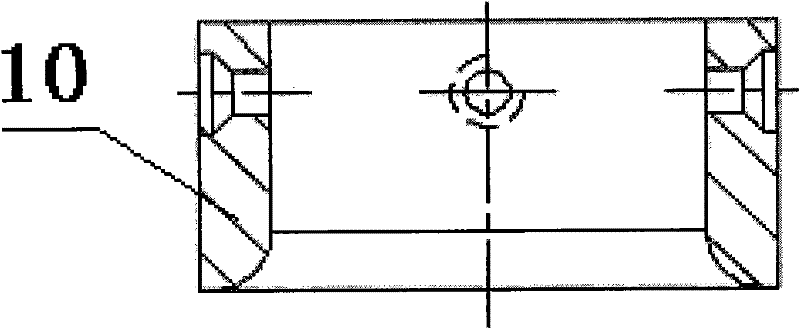

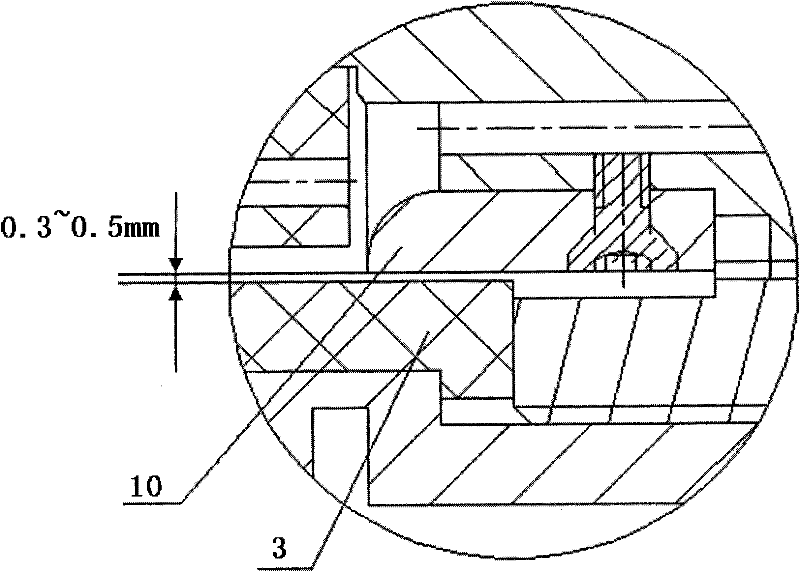

Tool arranged on ring rolling machine for automatically rolling wind power L-shaped flange and method of tool

InactiveCN114608414AEasy to processEasy to measureMechanical depth measurementsMechanical thickness measurementsEngineeringMachine

Owner:SHANXI TIANBAO GRP CO LTD

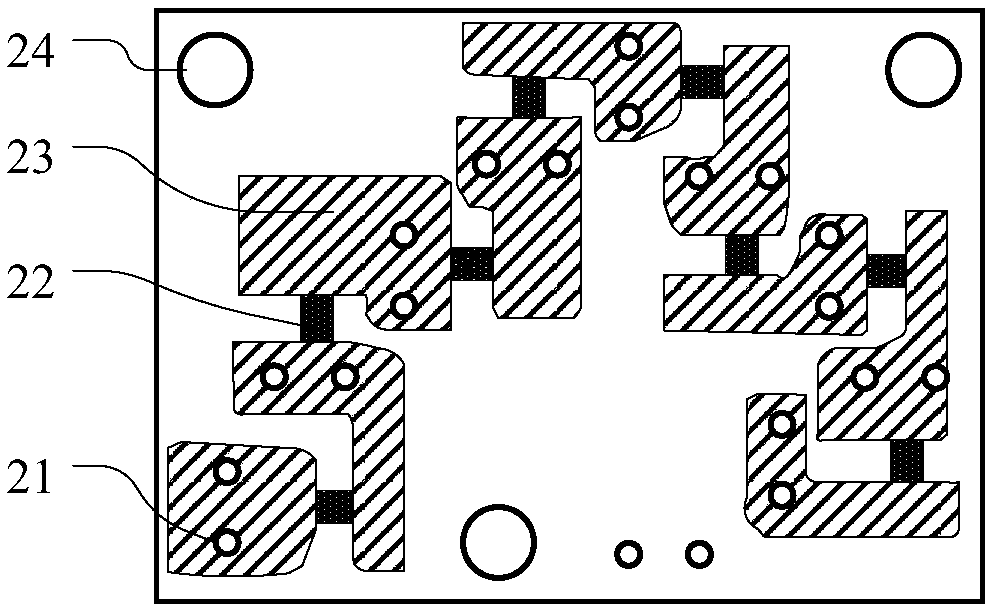

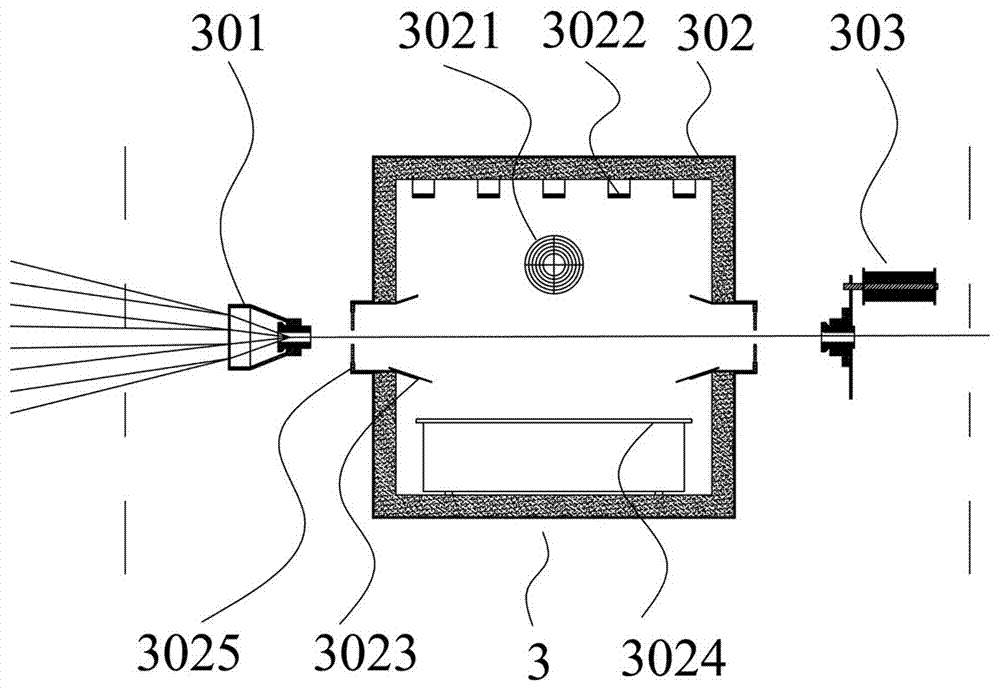

A structure of an electron multiplier and an assembly method thereof

ActiveCN109243959AReduce assembly linksSave spaceElectron multiplier detailsVessels or leading-in conductors manufactureElectricityElectrical connection

The invention discloses a structure and an assembly method of an electron multiplier, An electron multiplier is composed of a low substrate, an upper substrate motherboard, an upper substrate assistedplate, a dozen electrode assembly and a collector assembly; A plane-type voltage dividing resistor and a flat-type transition electrode are arranged on the upper surface of the upper substrate main board, A main board of that upper substrate is provide with a dozen mounting hole corresponding to an electrical connection hole of the dozen assembly, A surface-type transition electrode is electrically connected with that mounting hole of the dozen electrode, A planar voltage dividing resistor and a planar transition electrode are partially overlapped and electrically connected, Then, the dozen electrode assembly and the collector assembly are fixed between the lower substrate and the upper substrate main board, and the upper substrate auxiliary board is fixed on the upper end of the upper substrate main board, so that the space between the upper substrate auxiliary board and the upper substrate main board is reduced, the resistor film layer and the transition electrode film layer are partially overlapped, and the electrical connection is very reliable; The voltage dividing resistor, the transition electrode and the upper substrate main board are integrated into one body, and each voltage dividing resistor need not be soldered one by one, and the structure is compact, so that the assembly link of the soldering resistor is reduced.

Owner:XI AN JIAOTONG UNIV

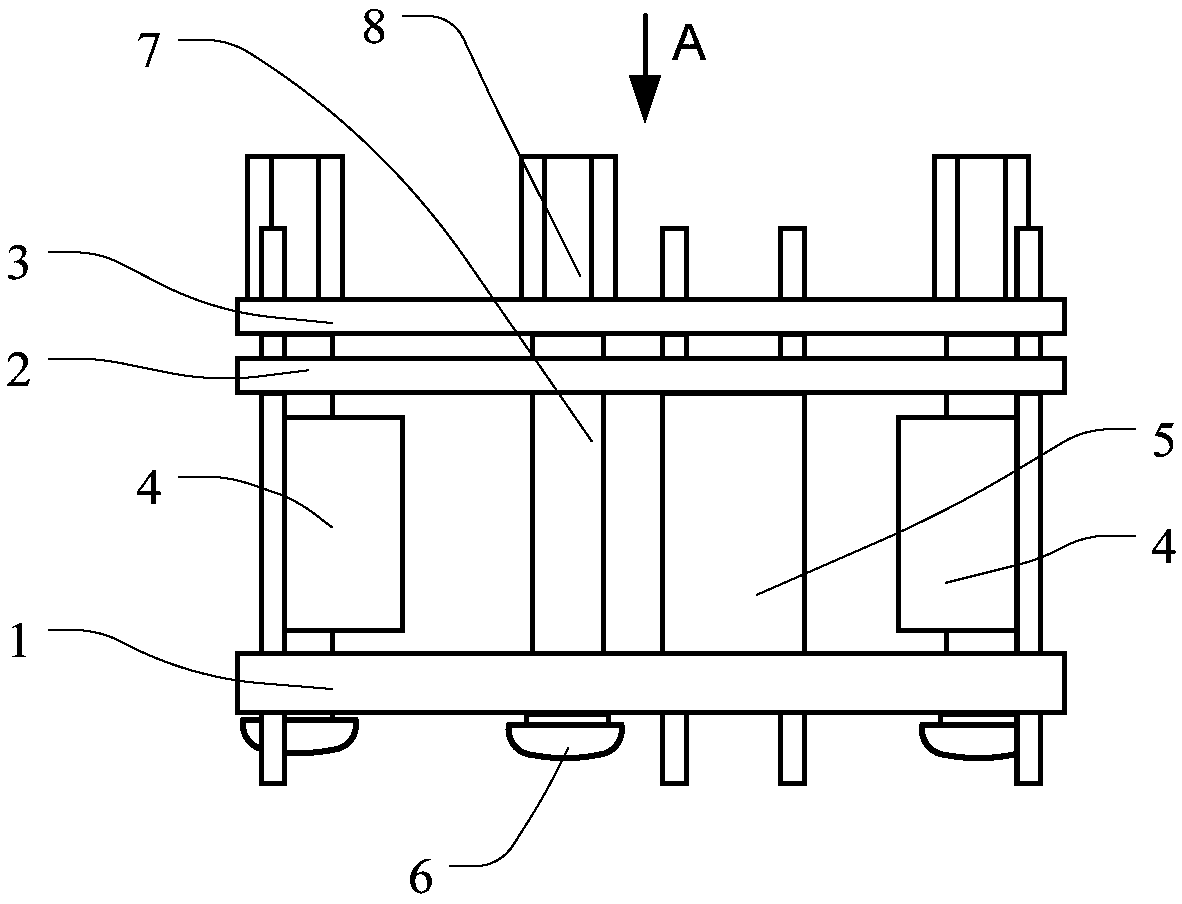

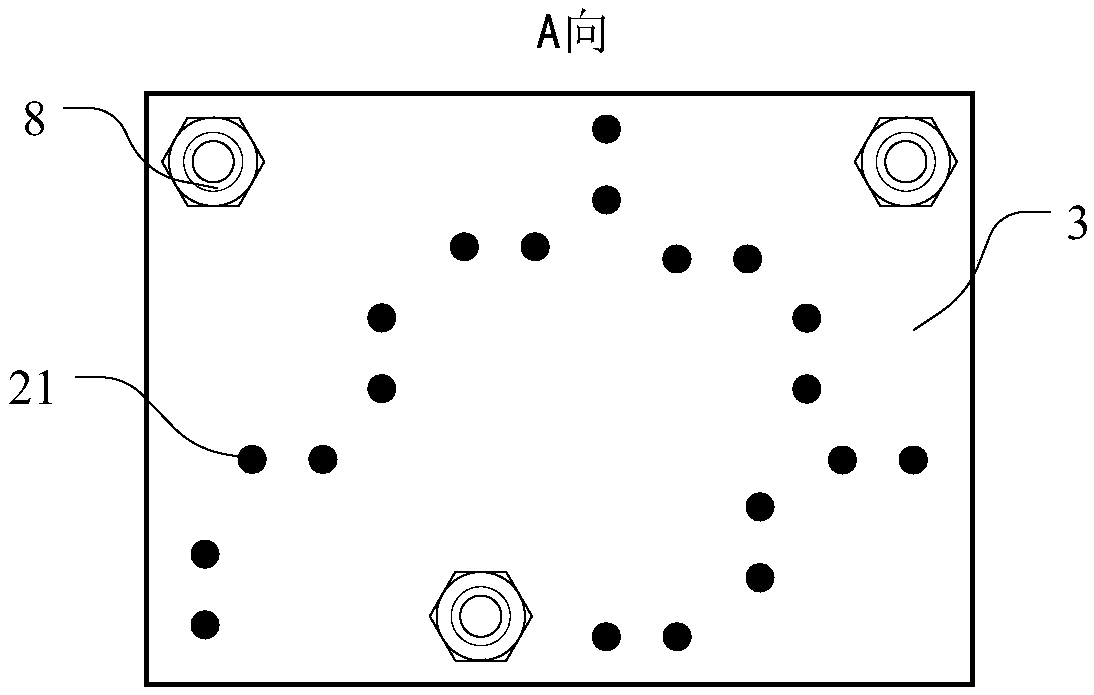

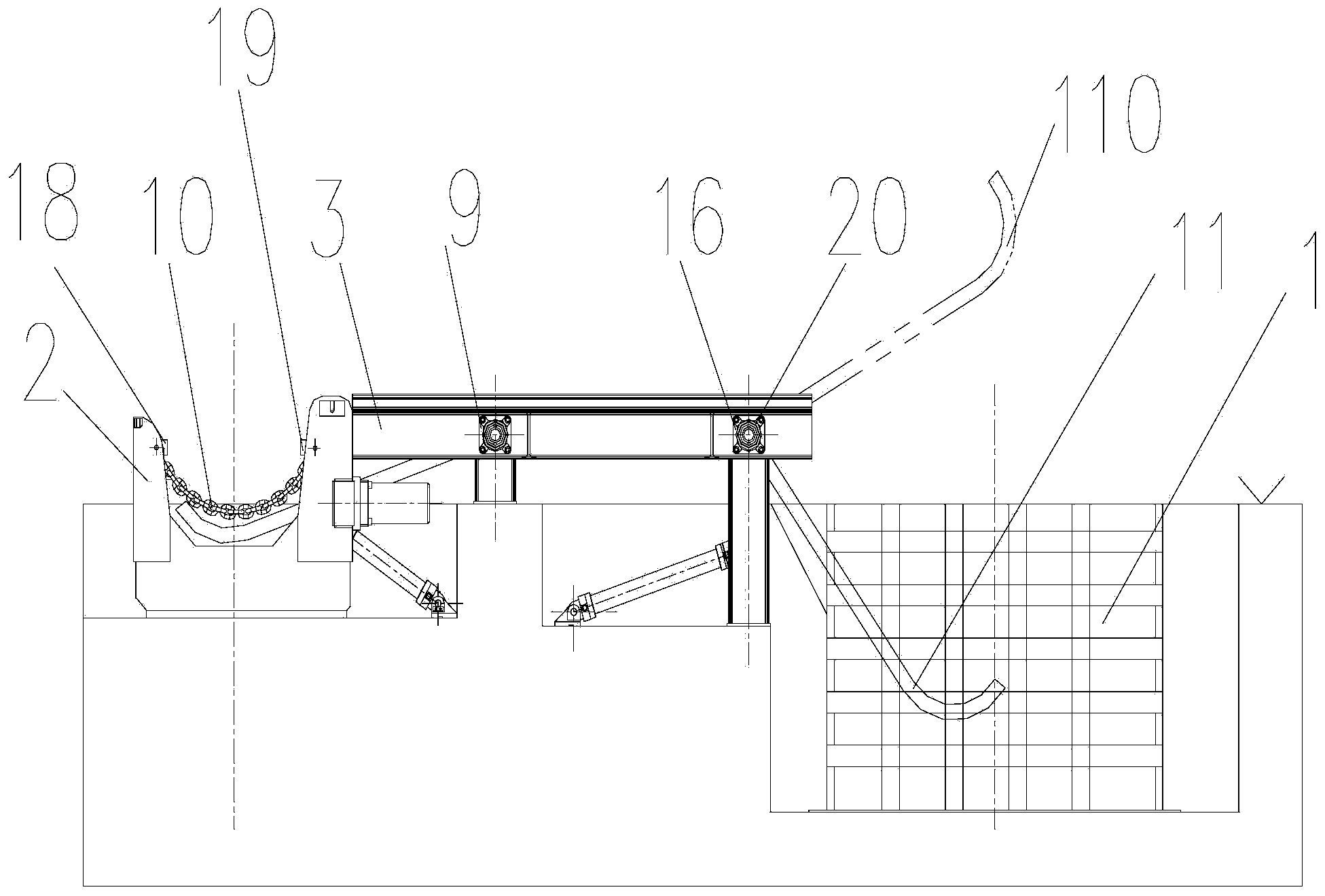

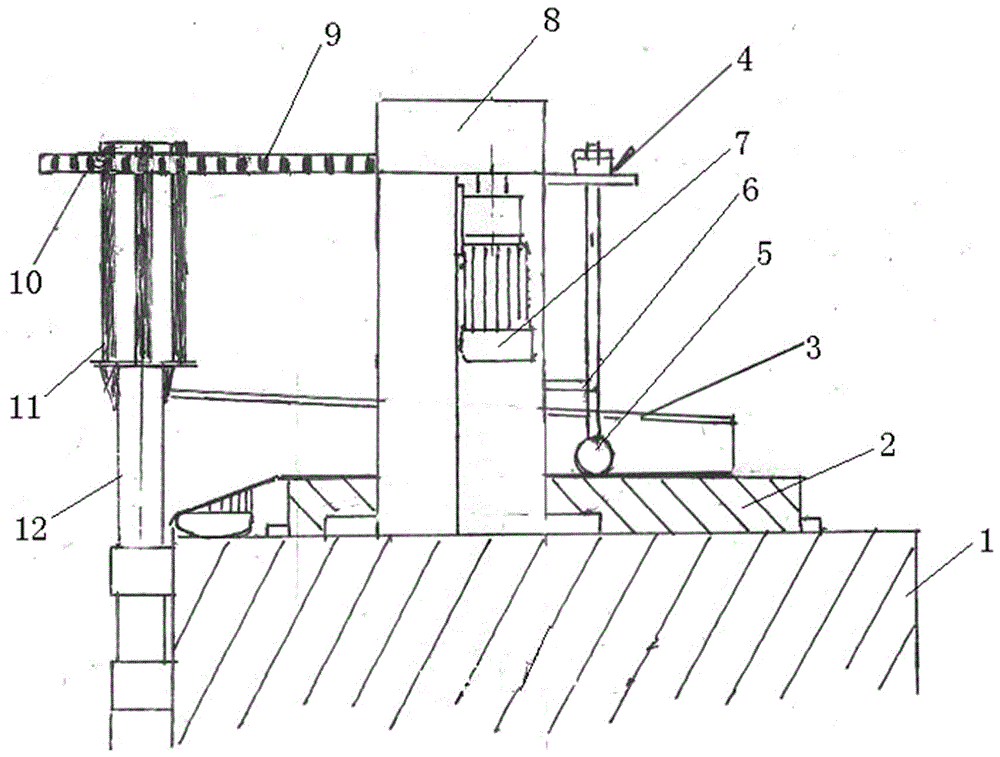

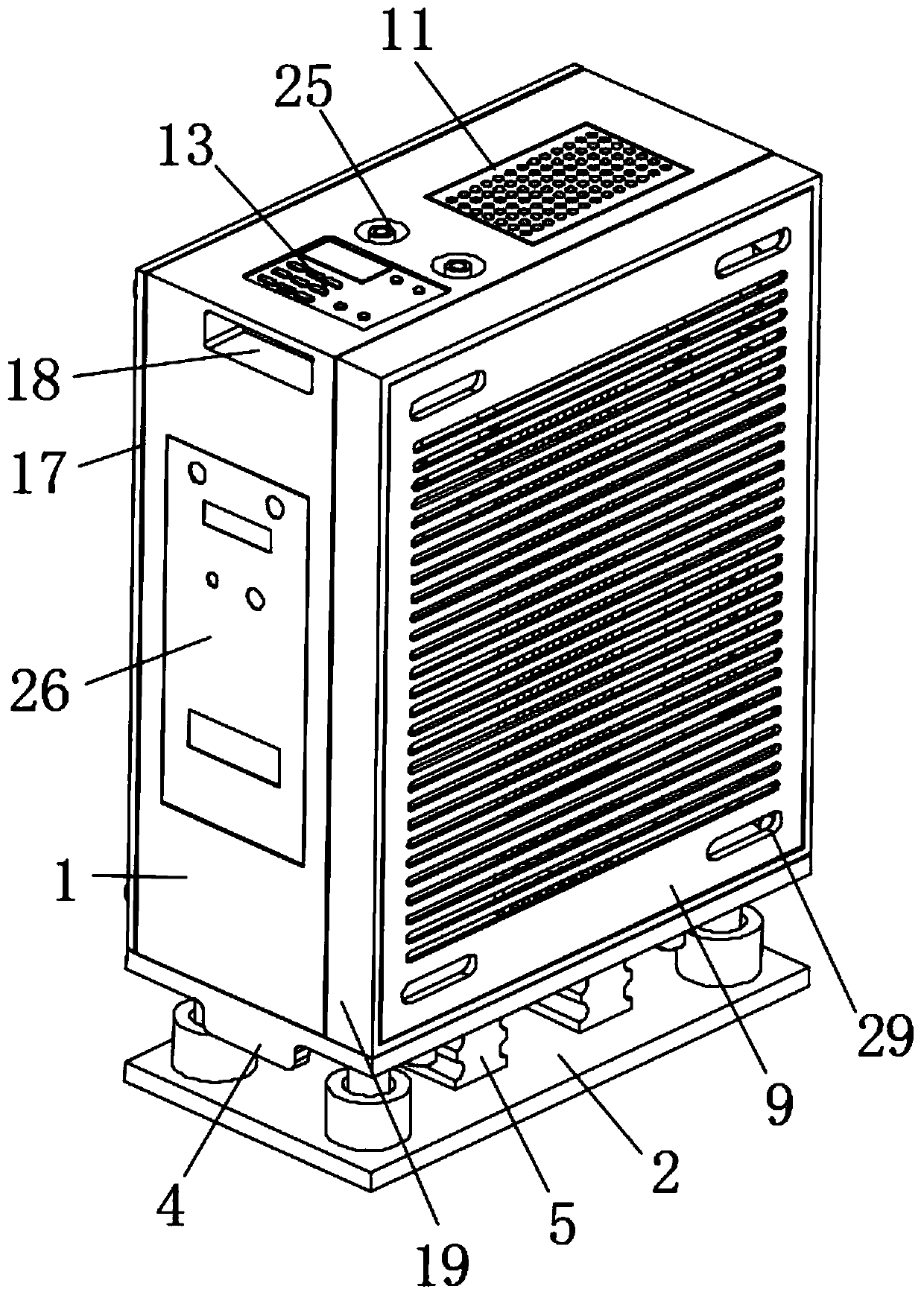

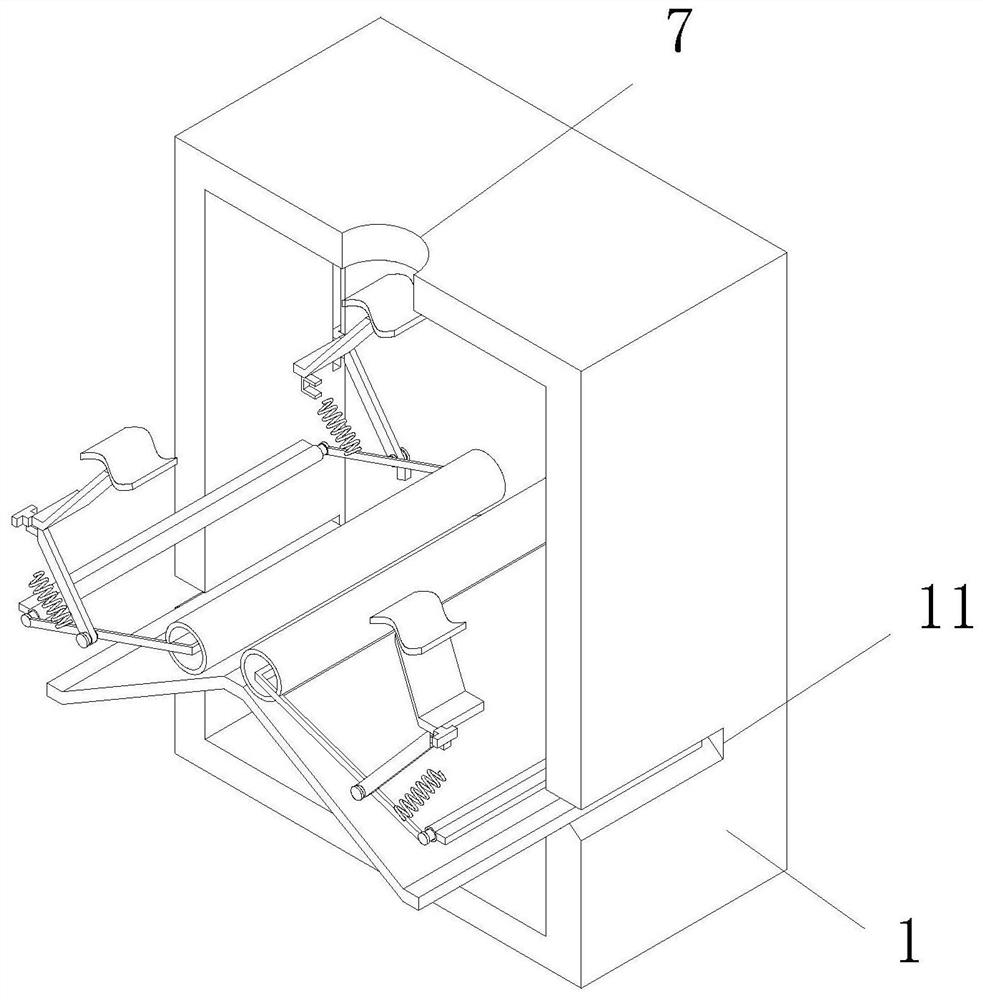

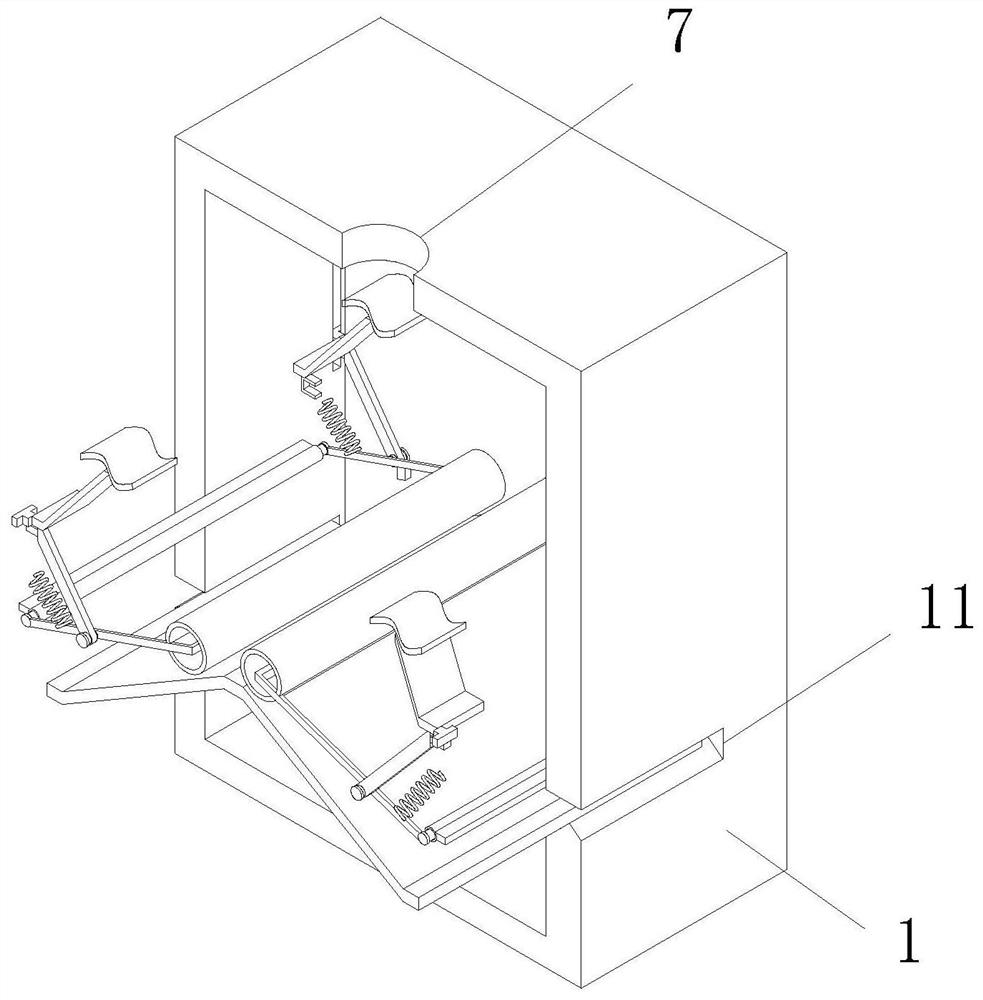

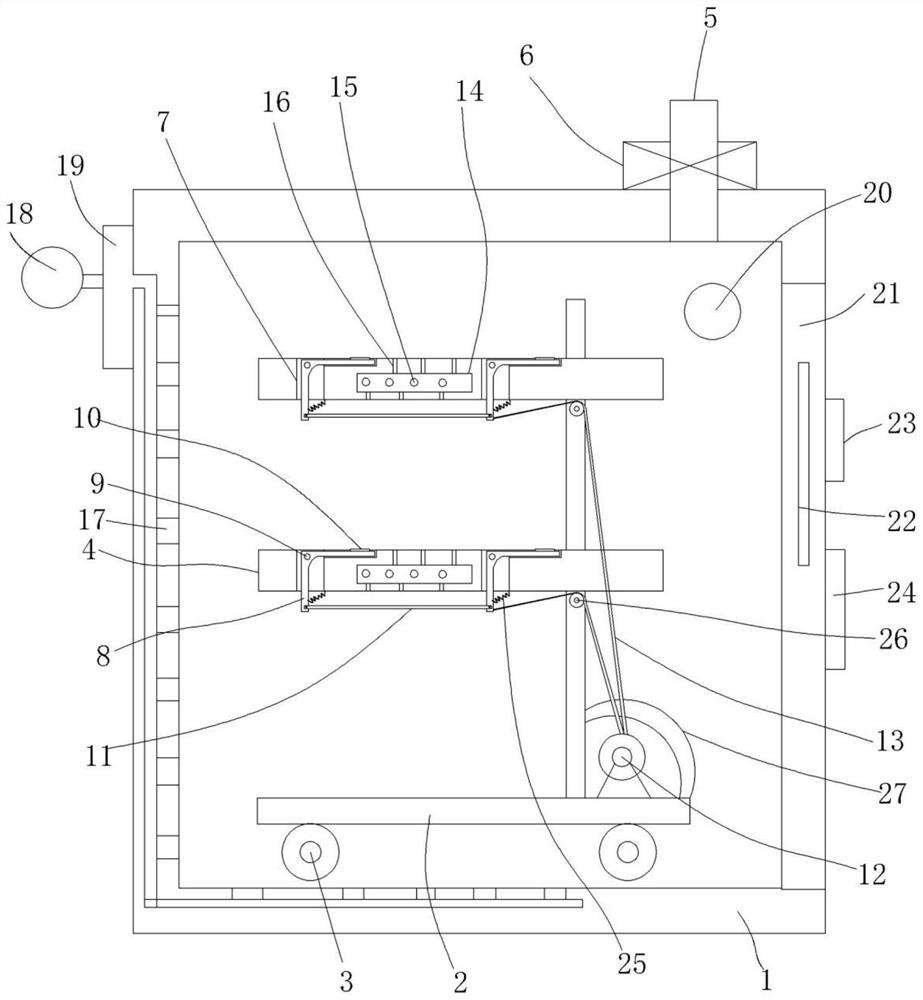

Quenching machine applied to mandrel heat treatment

ActiveCN103643019AReduce manual lifting timeSave loading timeFurnace typesHeat treatment furnacesQuenchingWater tanks

The invention provides a quenching machine applied to mandrel heat treatment. The quenching machine applied to the mandrel heat treatment comprises a charging basket, a feeding arm arranged at a side opening of the charging basket, a material rest which is used for supporting a mandrel and provided with an inlet end and an outlet end, a first hydraulic cylinder connected with the feeding arm, a quenching arm hinged at the outlet end of the material rest, a second hydraulic cylinder connected with the quenching arm and a water tank arranged at the outlet end of the material rest, wherein the feeding arm is hinged at the inlet end of the material rest; the inlet end is located in the rotating area of the feeding arm; the outlet end is located at the rotating area of the quenching arm; the rotating area of the quenching arm passes through the water tank. The quenching machine provided by the invention is capable of realizing the functions of automatic feeding and blanking, so that the feeding time can be reduced to the greatest extent.

Owner:CERI TECH +1

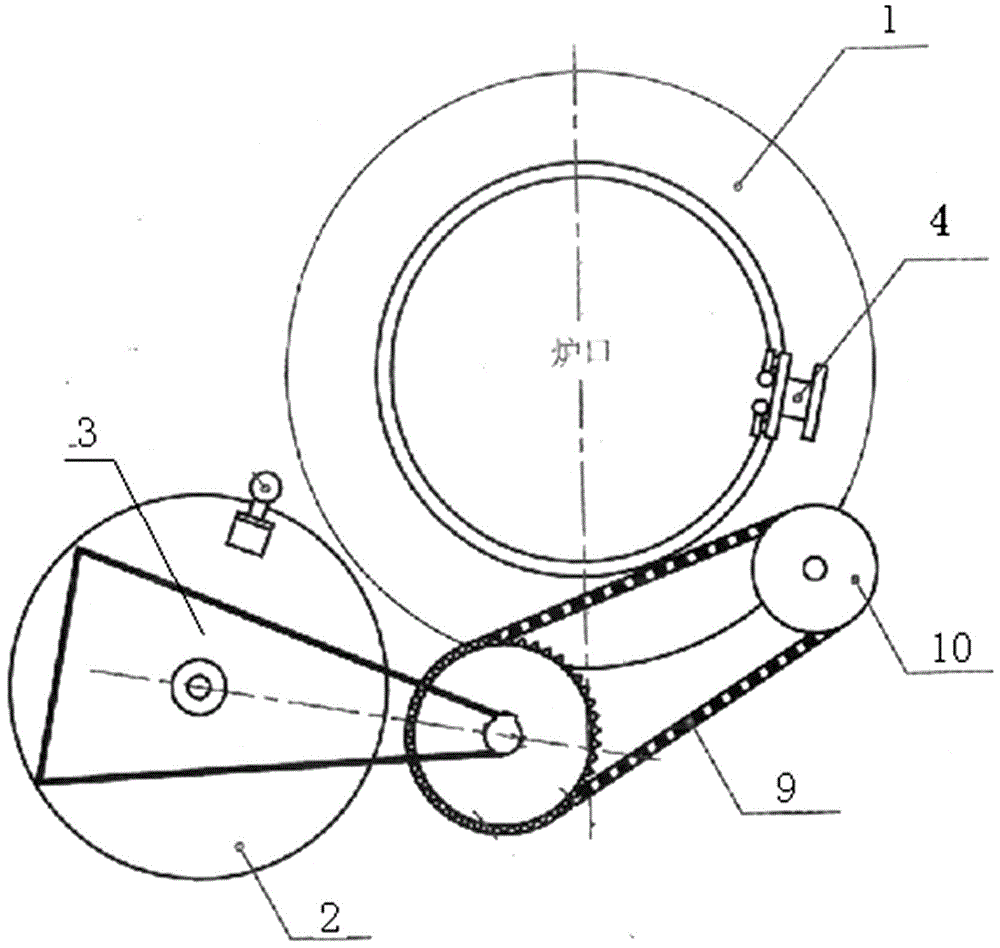

Method for preventing molten iron of torpedo tank from being sprinkled due to reverse rotation

ActiveCN102717057AEliminate inversion problemsAvoid bakingMelt-holding vesselsMaximum diameterNormal state

The invention provides a method for preventing molten iron of a torpedo tank from being sprinkled due to reverse rotation. According to the method, a trigger baffle is arranged at the position of the maximum diameter of a tank body on the reversal side of the torpedo tank; a travel switch with a trigger touch plate is arranged on a wall opposite to the trigger baffle; a trigger rod is hinged to the front end of a support below the travel switch; the travel switch is connected with a contactor connected with a torpedo tank tipping power electric circuit and is in the closed state in the normal state; when the torpedo tank rotates reversely, the trigger baffle triggers the travel switch by the trigger rod and the trigger touch plate, so that the travel switch is turned off; and the contactor and the tipping power electric circuit which are connected with the travel switch are powered off, so that the torpedo tank stops rotating reversely. By the method, the problem of the reverse rotation of the torpedo tank due to misoperation or the failure of equipment components during the pouring of the molten iron can be avoided fundamentally, iron sprinkling accidents are eliminated, the loss of the accidents is avoided, the service life of the travel switch is prolonged, and the running reliability is improved.

Owner:ANGANG STEEL CO LTD

Cylinder head

InactiveUS7757654B2Increased durabilityAvoid bakingCylinder headsCylindersCylinder headStructural engineering

A cylinder head in which a partition wall for separating exhaust ports of adjoining cylinders extends from between these adjoining cylinders to an exhaust merging portion and the partition wall is formed with a head bolt insertion hole inside it, an oil passage is formed in the partition wall between the front end of the partition wall facing the exhaust merging portion and the head bolt insertion hole, and a heat insulating layer is formed inside the partition wall between the front end of the partition wall and the oil passage.

Owner:TOYOTA JIDOSHA KK

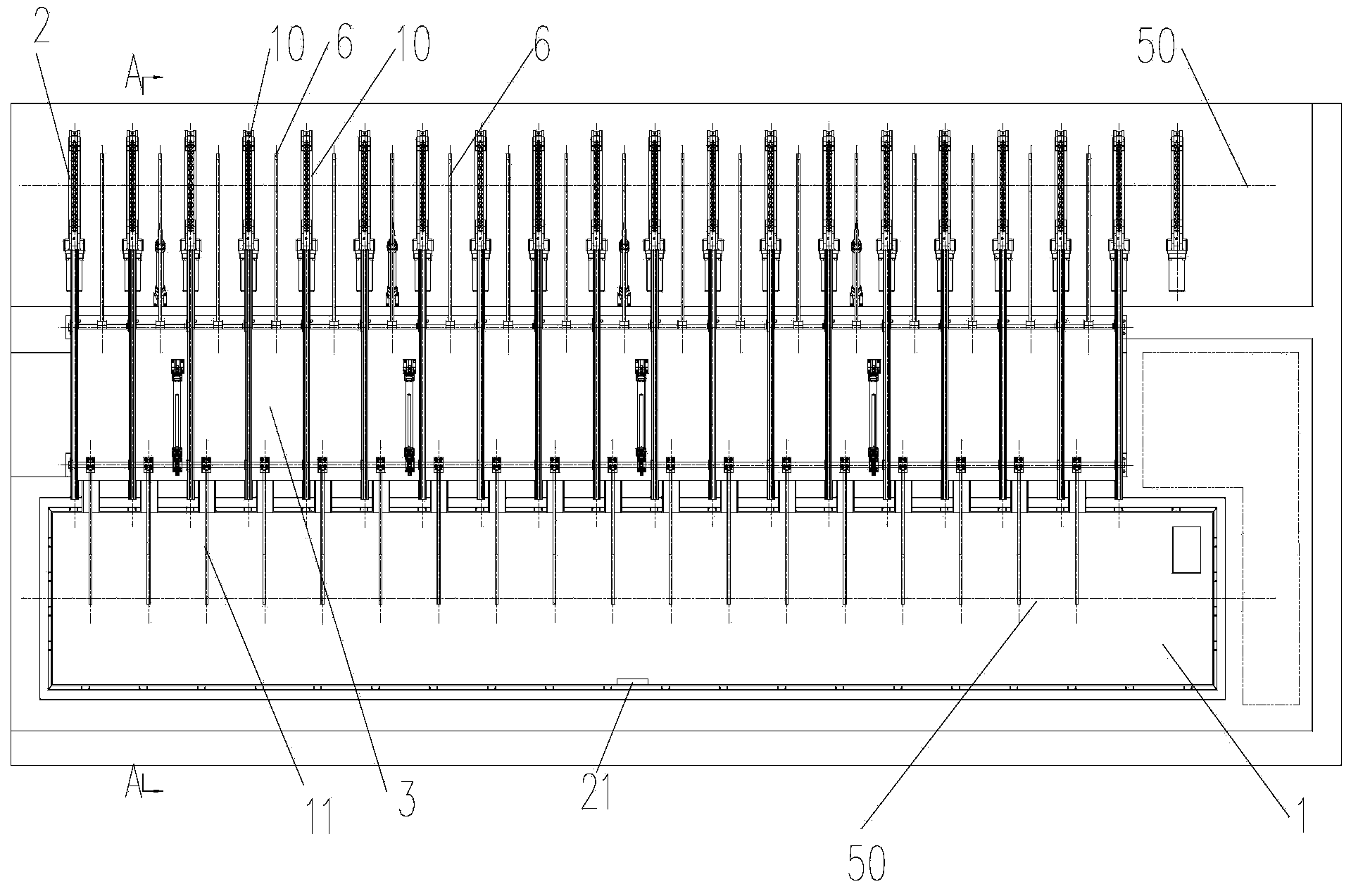

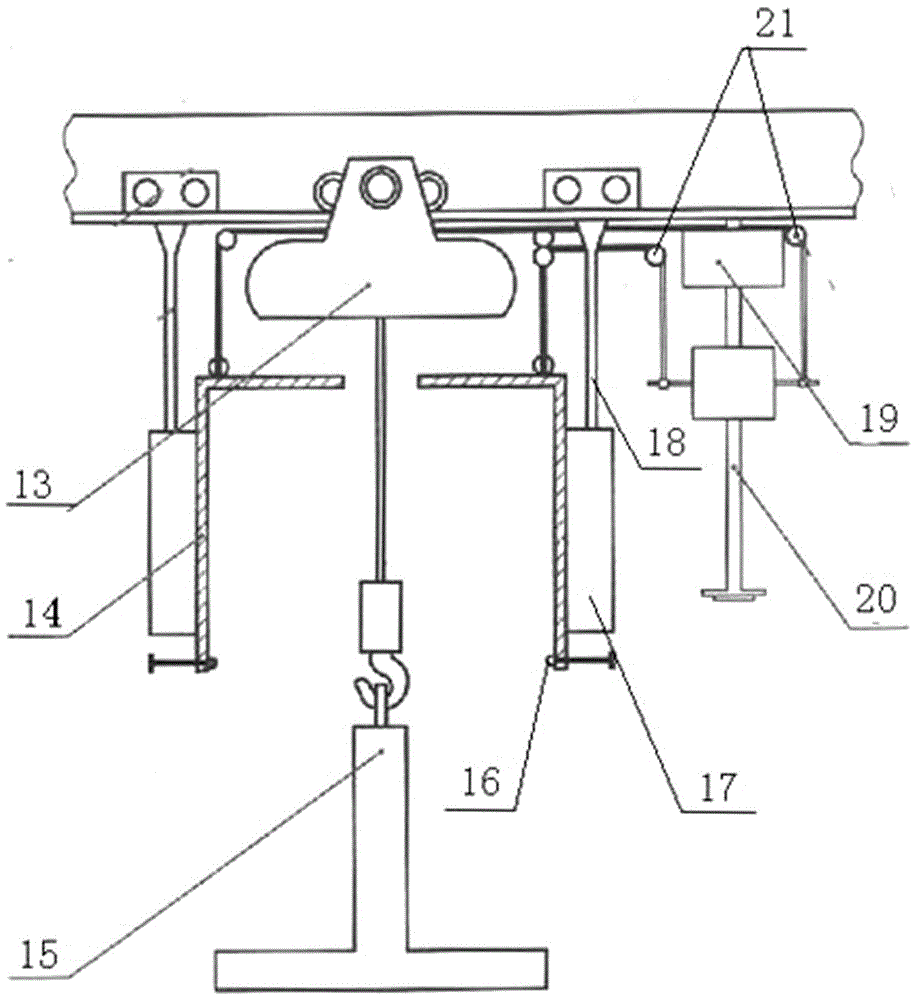

Automatic production type heat treatment pit furnace and accessory device

ActiveCN106370011AEliminates wobbleAccelerateRemovable covers for furnacesEngineeringMaterial resources

An automatic production type heat treatment pit furnace comprises a pit furnace lid automatic lifting and rotating device, a pit furnace lifting material disk movable shield locking device, a program control crane automatic hanging device and a crane advancing accurate braking device. The pit furnace lid automatic lifting and rotating device enables a furnace lid to automatically ascend and rotate and enables a lid lock to be automatically released, when the furnace lid returns to the original position, the lid lock is made to be automatically locked, and therefore the furnace lid is accurately covered. The pit furnace lifting material disk movable shield locking device effectively eliminates shake generated when a steel wire rope lifting disk walks, and a shield can prevent cooling and oxidation. According to the program control crane automatic hanging device, when a lifting hook is locked in one direction, the lifting hook is made to be automatically hung on a lifting ring, automatic unhooking can also be achieved, unsafe factors existing during manual hanging are eliminated, the hanging speed is improved, and workers are prevented from being roasted by high-temperature furnace fire. A chain accurately brakes in the advancing process of a crane, and errors caused by the inertia of the crane are avoided. The automatic production type heat treatment pit furnace saves labor, material resources and financial resources and improves the product quality and the production efficiency.

Owner:WAFANGDIAN GUANGDA BEARING MFG

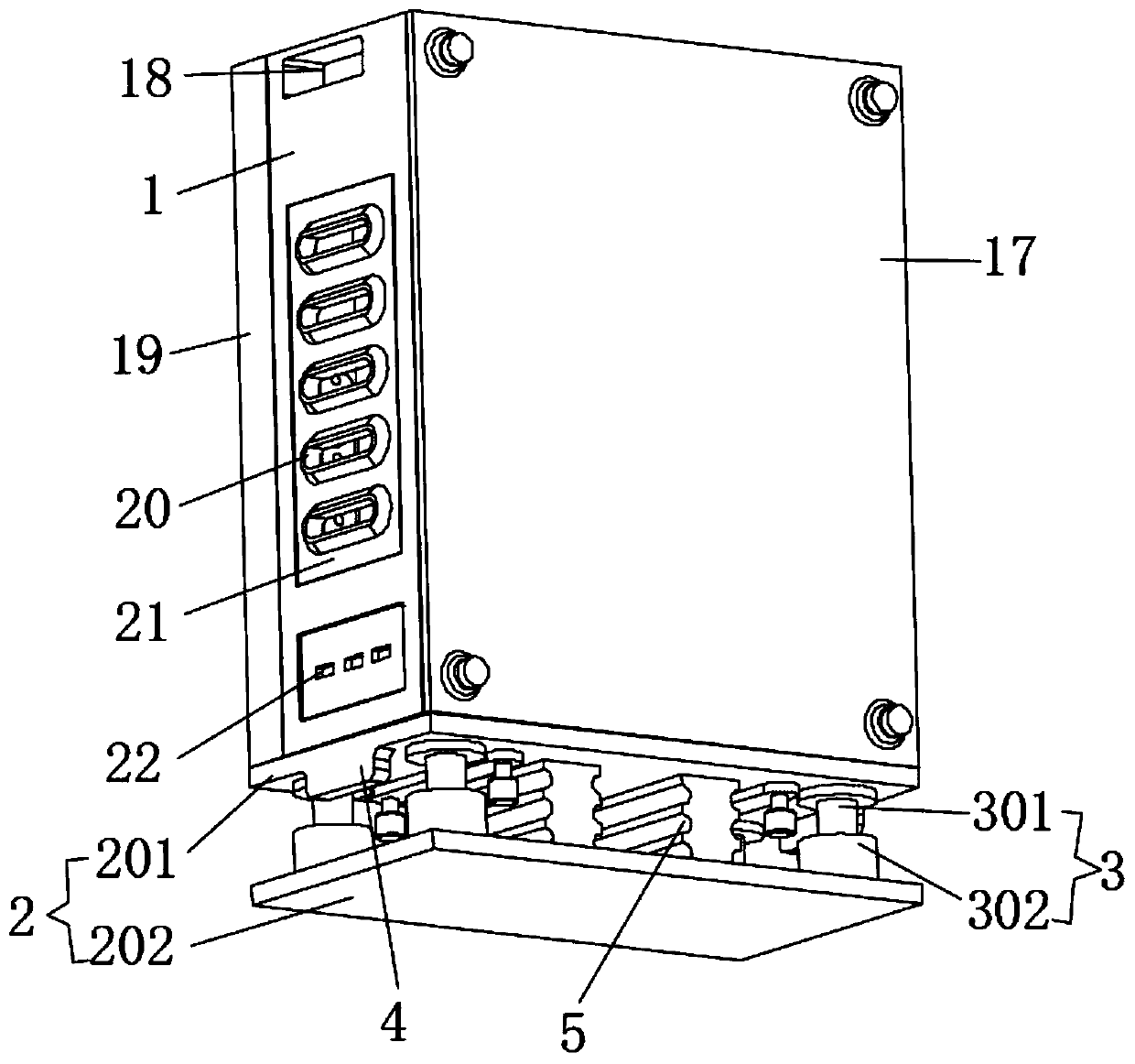

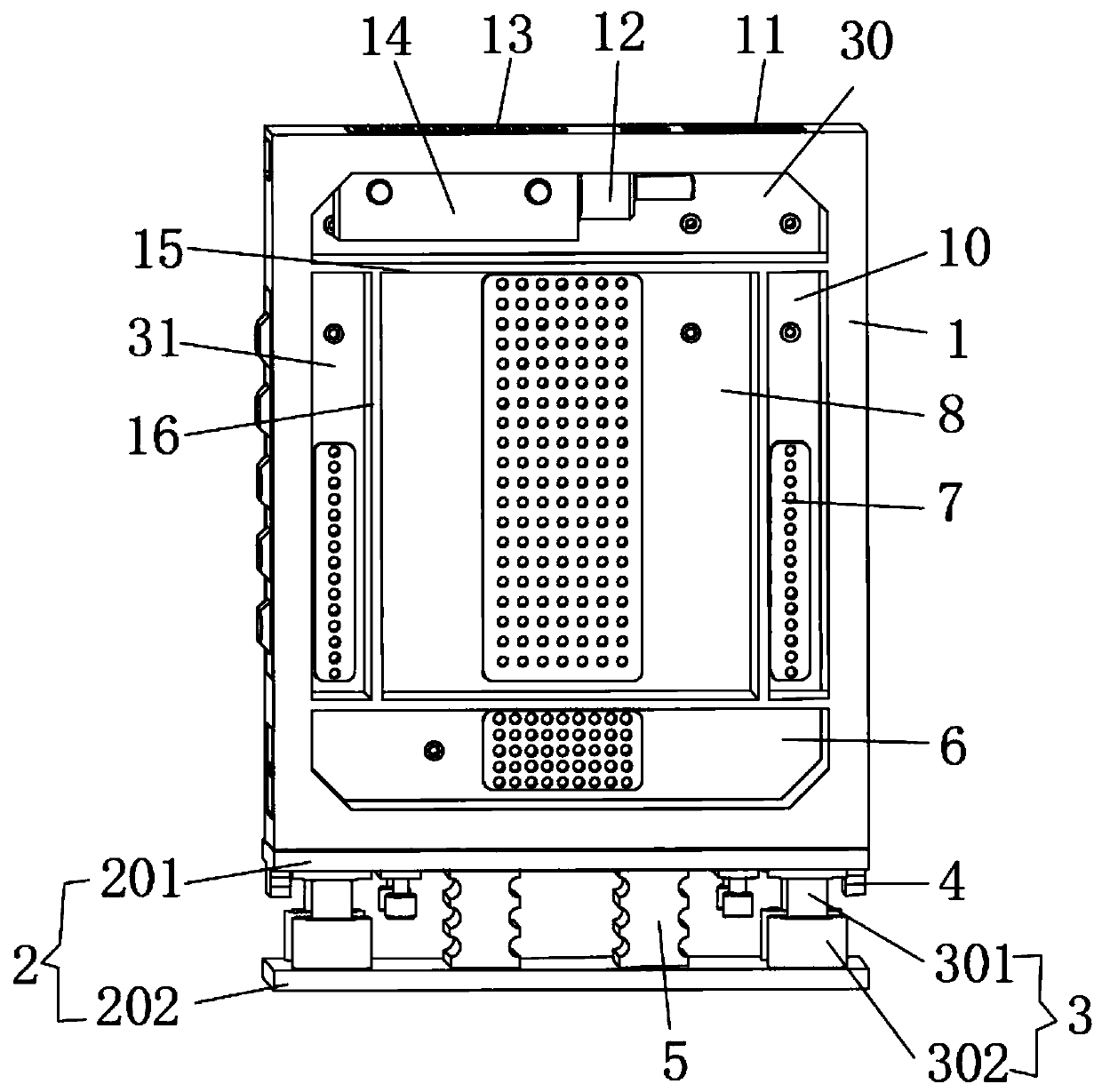

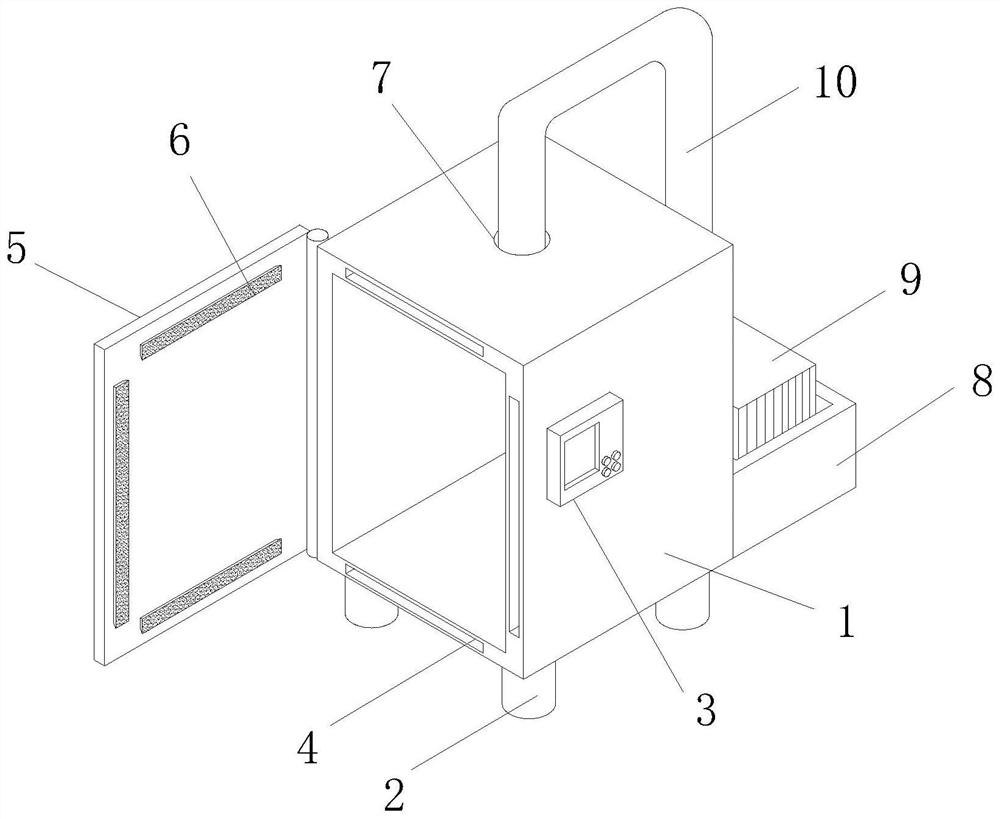

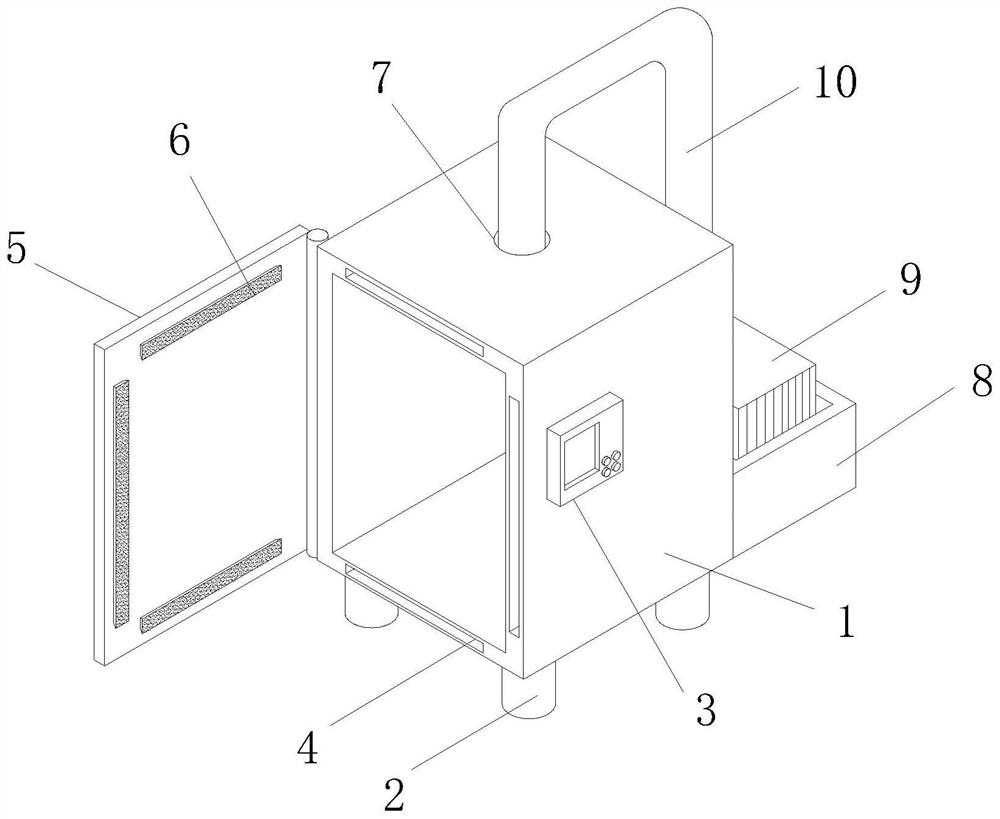

Partitioned cooling type computer mainframe box

InactiveCN111562824AAvoid bakingExtended service lifeDigital processing power distributionPhysicsComputer equipment

The invention relates to the technical field of computer equipment, particularly relating to a partitioned cooling type computer mainframe box comprises a main shell, a pair of transverse partition plates is fixedly installed in the main shell through bolts, the interior of the main shell is divided into an air cavity, a middle containing cavity and a bottom containing cavity through the transverse partition plates from top to bottom, and a pair of vertical partition plates is fixedly installed between the transverse partition plates through bolts. The beneficial effects are that: internal equipment of the main shell is mounted in different areas through the bottom containing cavity, the middle containing cavity, the front containing cavity and the bottom containing cavity which are isolated from one another in the main shell; therefore, a fan is used for carrying out uniform partitioned cooling; in the cooling process, the air flow flowing path can be effectively controlled, coolingdead corners are avoided, the situation that main heat dissipation components bake other components can be effectively avoided, and therefore the heat dissipation effect is improved, the service lifeof the components is prolonged, the better dustproof effect is achieved, and maintenance and management of a computer are facilitated.

Owner:合肥万古网络科技有限公司

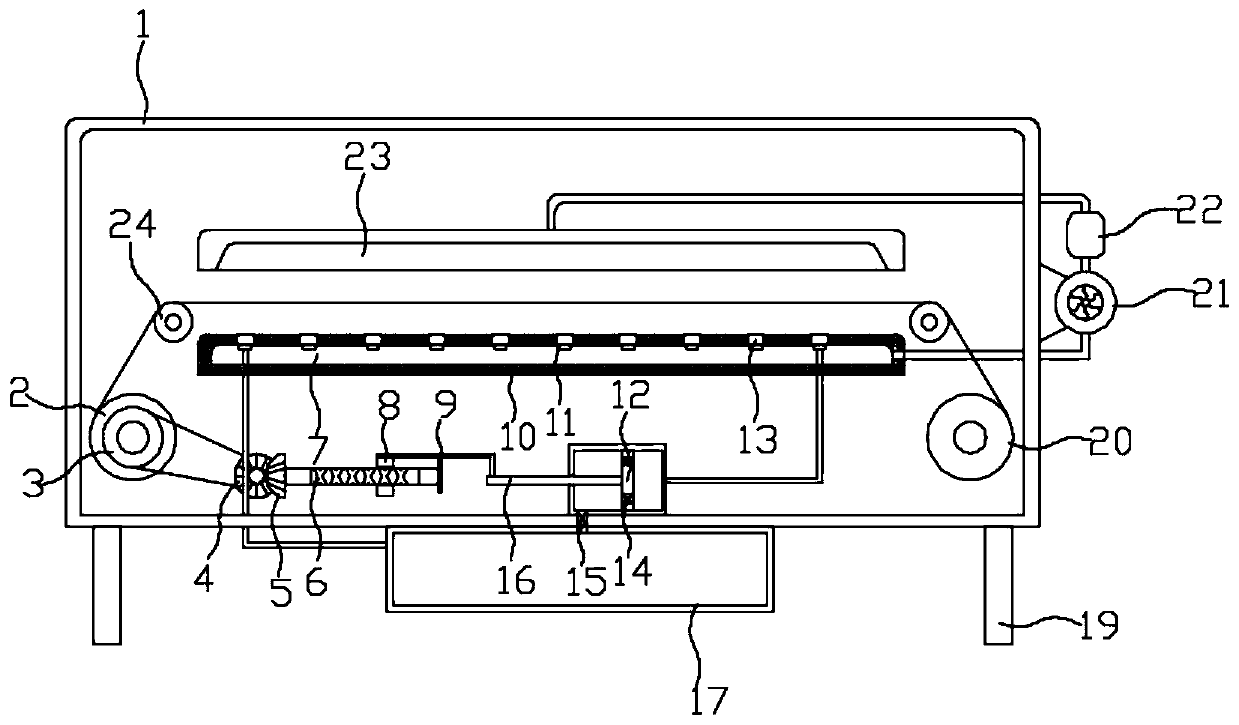

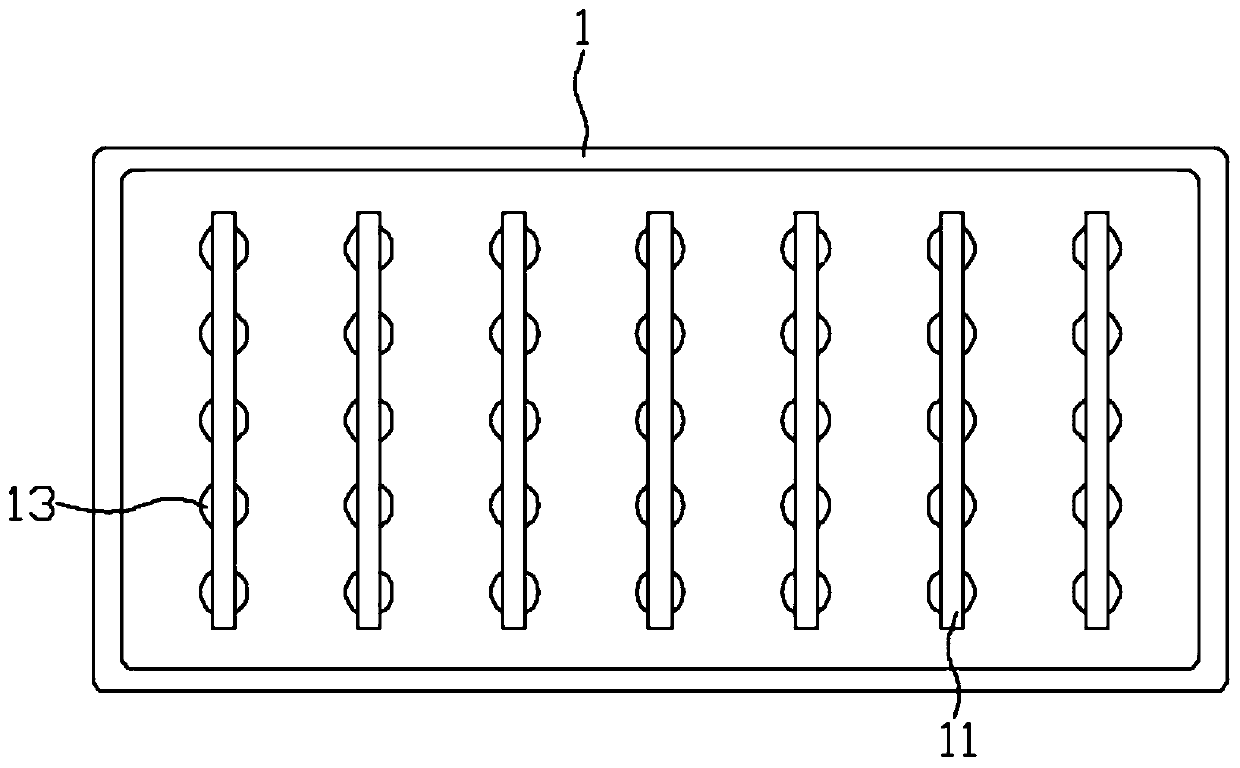

Progressive waste heat circulation drying system for fabric

InactiveCN110331538AAvoid bakingReduce wasteLiquid/gas/vapor removal by squeezing rollersTextile treatment machine arrangementsWater vaporWater flow

The invention discloses a progressive waste heat circulation drying system for fabric. The system comprises a tank, wherein supporting legs are arranged at the lower end of the tank, a winding rollerand a driving roller are arranged in the tank, a horizontal transverse plate is fixedly connected to the inner wall of the tank, a cavity is formed in the transverse plate, and air holes communicatedwith the cavity are uniformly distributed in the upper end of the transverse plate. By progressive drying of the fabric, the dried fabric can be effectively prevented from being damaged by airflow with higher temperature through drying; hot air carrying water vapor is collected to enter a fan through a gas collecting cover, and the water vapor is filtered out by a drying mechanism for next use, and meanwhile, used hot water flows back into a heating box for recycling, so that waste of heat energy is reduced; the driving roller rotates to drive a driving mechanism to work to press water, and the cost of the system is reduced.

Owner:温州浩僧服饰有限公司

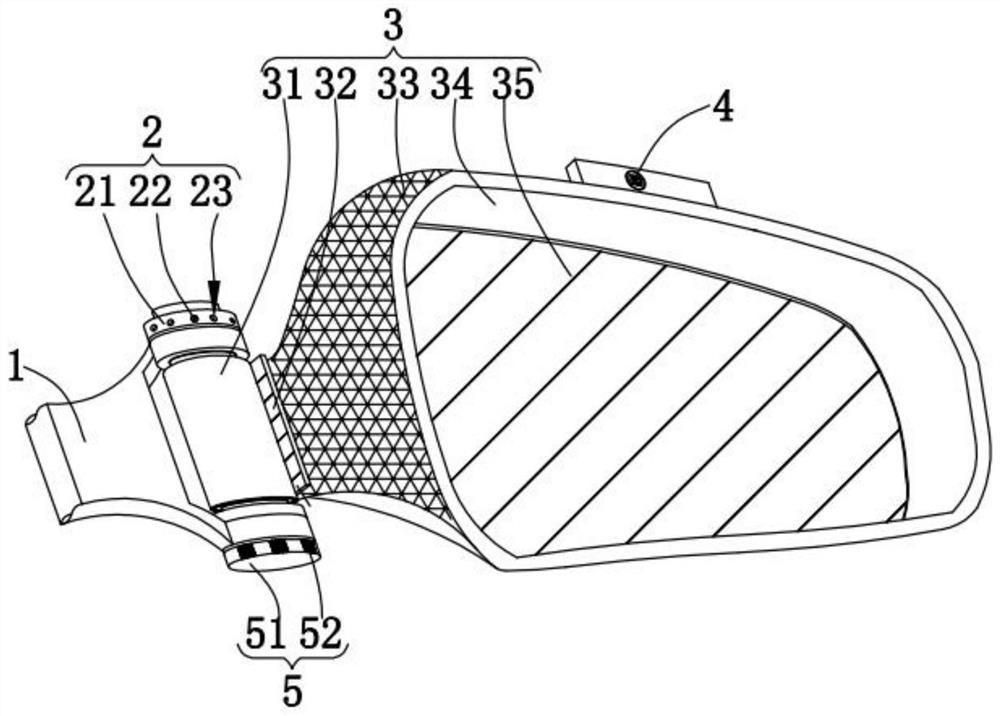

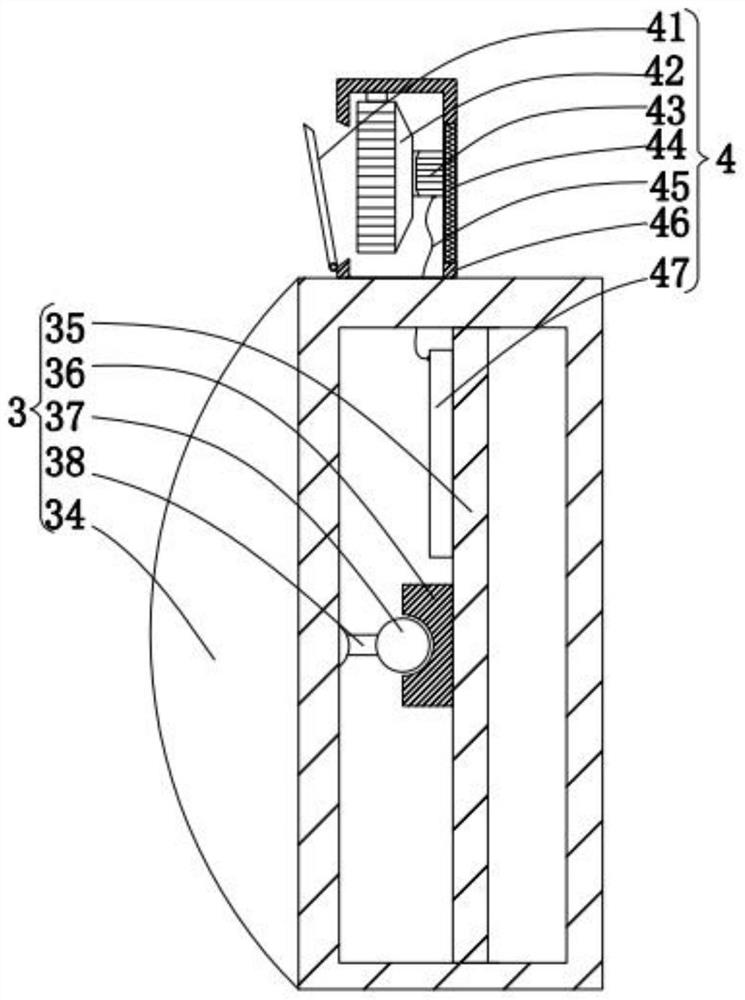

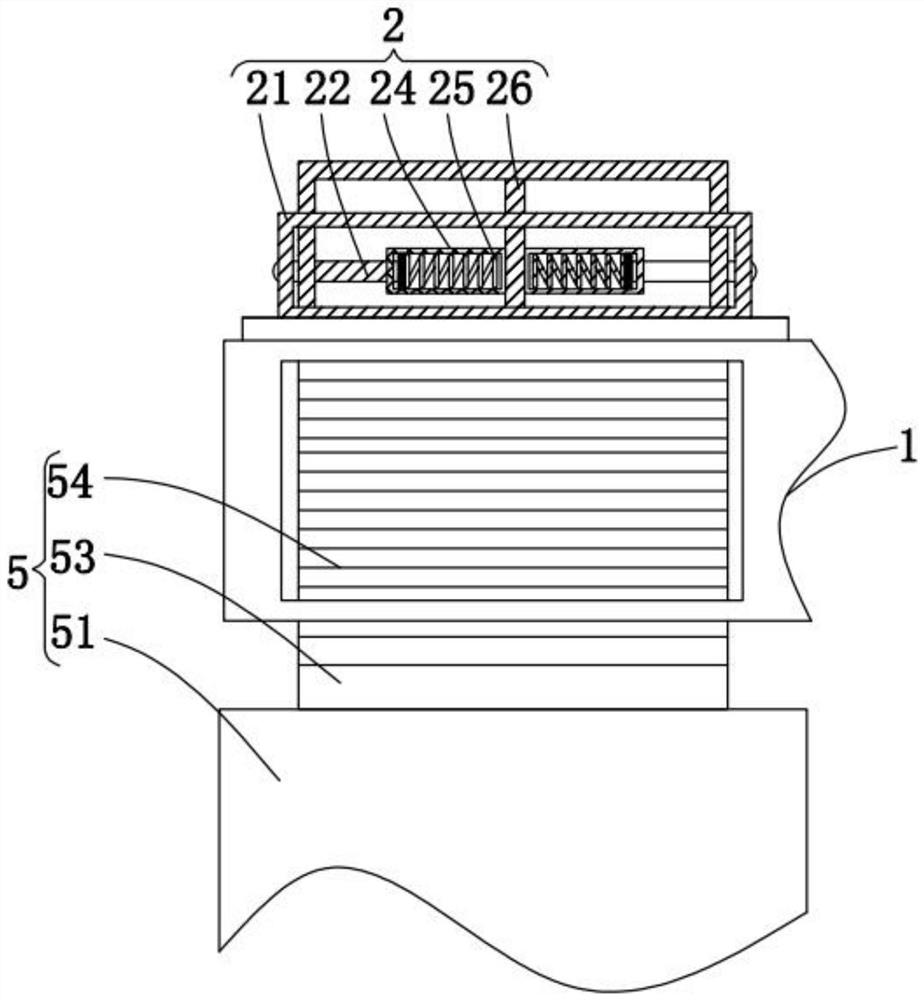

A car rearview mirror with adjustable angle

ActiveCN109532680BAvoid bakingEasy to driveVehicle cleaningOptical viewingDriver/operatorConstant power

The invention relates to the field of automobile rearview mirrors, in particular to an automobile rearview mirror with an adjustable angle. The automobile rearview mirror comprises a fixing frame, anadjusting mechanism, an installing mechanism, a dehumidifying mechanism, a connecting mechanism, a first clamping mechanism, a second clamping mechanism and screws. A fixing box is installed at the top of a fixing shell, a fan is installed inside the fixing box, and a sealing plate is opened to drive the fan when an automobile is driven. Power generation of a generator is further realized, and a heat-conducting piece located on the back of the rearview mirror starts heating to dry up frost and rainwater, so that driving of a driver is easy; when there is no need to dry up the rainwater and frost on the rearview mirror, the sealing plate is closed, the fan is stopped from movement, furthermore, power generation of the generator is stopped, and it is avoided that under constant power generation of the heat-conducting piece, the rearview mirror is exploded during drying.

Owner:GAC HONDA AUTOMOBILE CO LTD

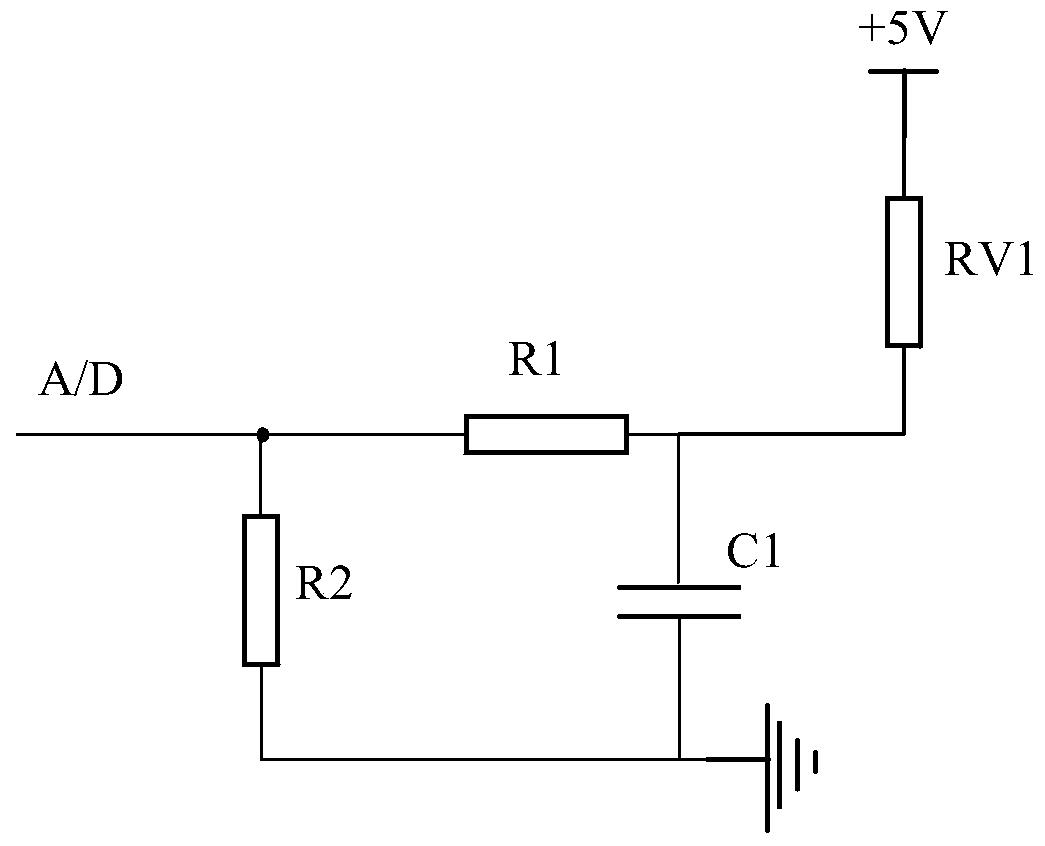

Dry burning prevention device and gas stove

PendingCN112032777AAvoid bakingIncreased durabilityDomestic stoves or rangesGaseous fuel burnerProcess engineeringMechanical engineering

The invention discloses a dry burning prevention device. The dry burning prevention device comprises a burner, an outer ring fire cover is arranged on the burner, a center fire cover is arranged in the outer ring fire cover, and a temperature sensor is arranged on the center fire cover. A heat insulation structure is further included and sleeves the temperature sensor, the flame is prevented fromdirectly contacting the temperature sensor, so that the temperature sensing accuracy of the temperature sensor is improved. The invention further discloses a gas stove. The gas stove comprises a bottom shell, a panel is fixedly connected to the bottom shell, and the dry burning prevention device is arranged on the panel. According to the gas stove, the heat insulation structure sleeves the temperature sensor of the central fire cover, the telescopic temperature sensor is prevented from being baked by flame of a burner, the durability and the temperature sensing accuracy of the telescopic temperature sensor are enhanced, the misjudgment of the temperature is prevented, and the user experience is improved; and personal safety injury or other accidents possibly caused to users are reduced.

Owner:GREE ELECTRIC APPLIANCES INC

Composite frp bar preparation equipment

Owner:ZHENGZHOU UNIV

Front steel turning device of cogging mill

ActiveCN102310095BHigh positioning accuracyMeet the requirements of rolling processWork manipulationAutomatic controlEngineering

The invention relates to a front steel turning device of a cogging mill, which comprises an alternative roller (100), a base (200), a translation framework (300), a lifting mechanism (400), a turning mechanism (500), and a clamping roller mechanism (600). The alternative roller (100) is fixedly connected with the translation framework (300) and can move linearly along the base (200), the lifting mechanism (400) is arranged in the translation framework (300), the turning mechanism (500) is arranged on the side face of the lifting mechanism (400), the turning mechanism (500) and the lifting mechanism (400) can simultaneously move up and down along the inner side of the translation framework (300), the clamping roller mechanism (600) is connected with the output shaft of the turning mechanism (500) to realize synchronous rotation along with the turning mechanism (500), the translation framework (300), the lifting mechanism (400) and the clamping roller mechanism (600) are provided with adisplacement sensor, and the turning mechanism (500) is provided with an encoder. Automatic control of the whole steel turning process can be achieved, the positioning accuracy is high, and the device can be used conveniently and reliably, has a simple structure and low cost and can be maintained conveniently.

Owner:HUATIAN ENG & TECH CORP MCC

Production device of tencel bamboo fiber shirt fabric

ActiveCN112484425AImprove drying efficiencyAvoid concentrationDrying gas arrangementsDrying chambers/containersFiberElectric machinery

The invention provides a production device of tencel bamboo fiber shirt fabric, and belongs to the technical field of textile equipment. The device is characterized in that a fixing rod is arranged onthe outer circle wall surface of a sleeve shaft, wherein a rotating hole is formed in the outer wall of the fixing rod; a fixing block is fixedly installed on the outer wall of the fixing rod; an extension plate is fixedly installed on the outer wall of the fixing block; an air abutting plate is fixedly installed on the upper wall surface of the extension plate; and dried cloth is fixed inside adryer shell through a fixing clamp, the cloth is not leveled, a motor is connected with external power supply equipment, the motor drives a first magnet to rotate, when the first magnet rotates to correspond to the position of a through hole, the first magnet and a second magnet repel each other, at the moment, a connecting frame rotates upwards under the repelling force of the first magnet and the second magnet, a scraper rotates upwards along with the connecting frame to abut against the cloth, then the scraper rotates downwards under the acting force of a tension spring, the scraper moves up and down back and forth inside the dryer shell and continuously abuts against the cloth to drive the cloth to vibrate so as to shake off water in the cloth, and therefore the cloth drying efficiencyis improved.

Owner:浙江贤烨新材料科技有限公司

Inhibitors of protein kinases

InactiveUS8716296B2Improve flow characteristicsUniform and stable flowBiocideNervous disorderCyclinCyclin-dependent kinase

Owner:ASTRAZENECA AB

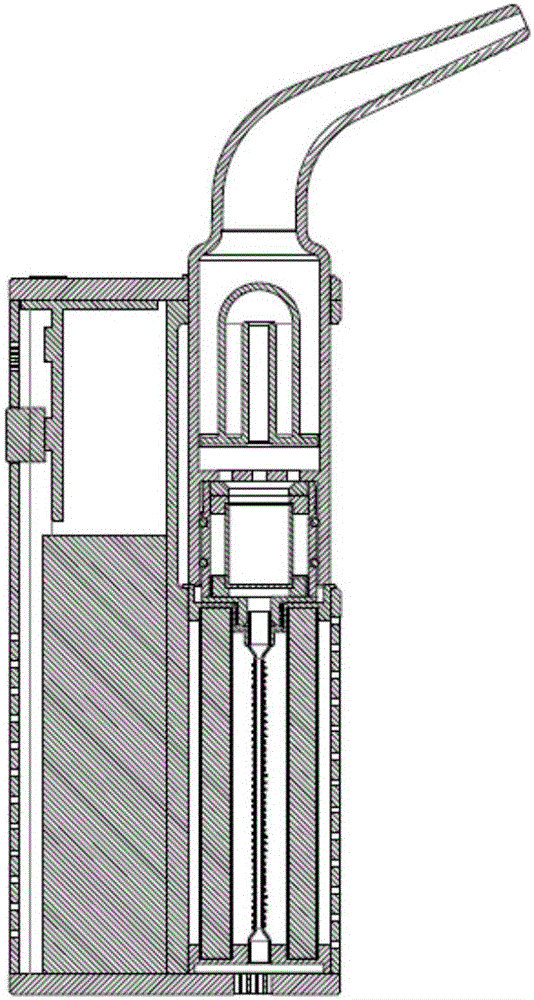

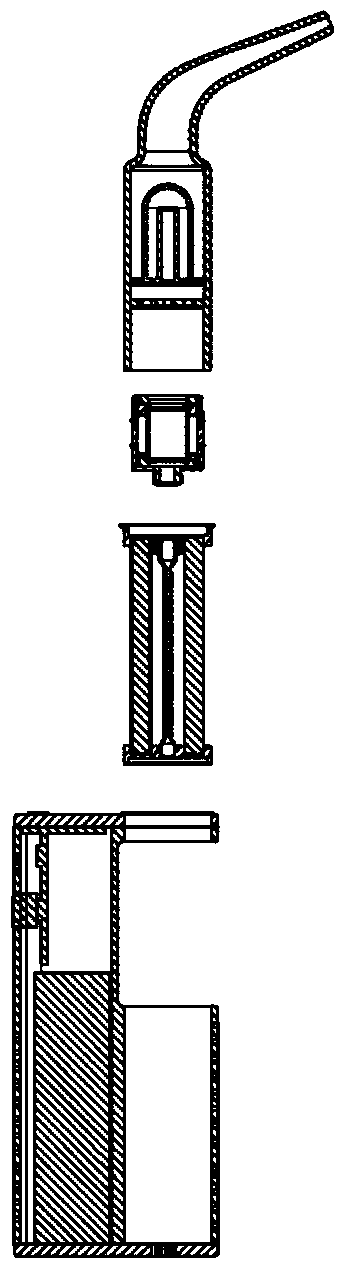

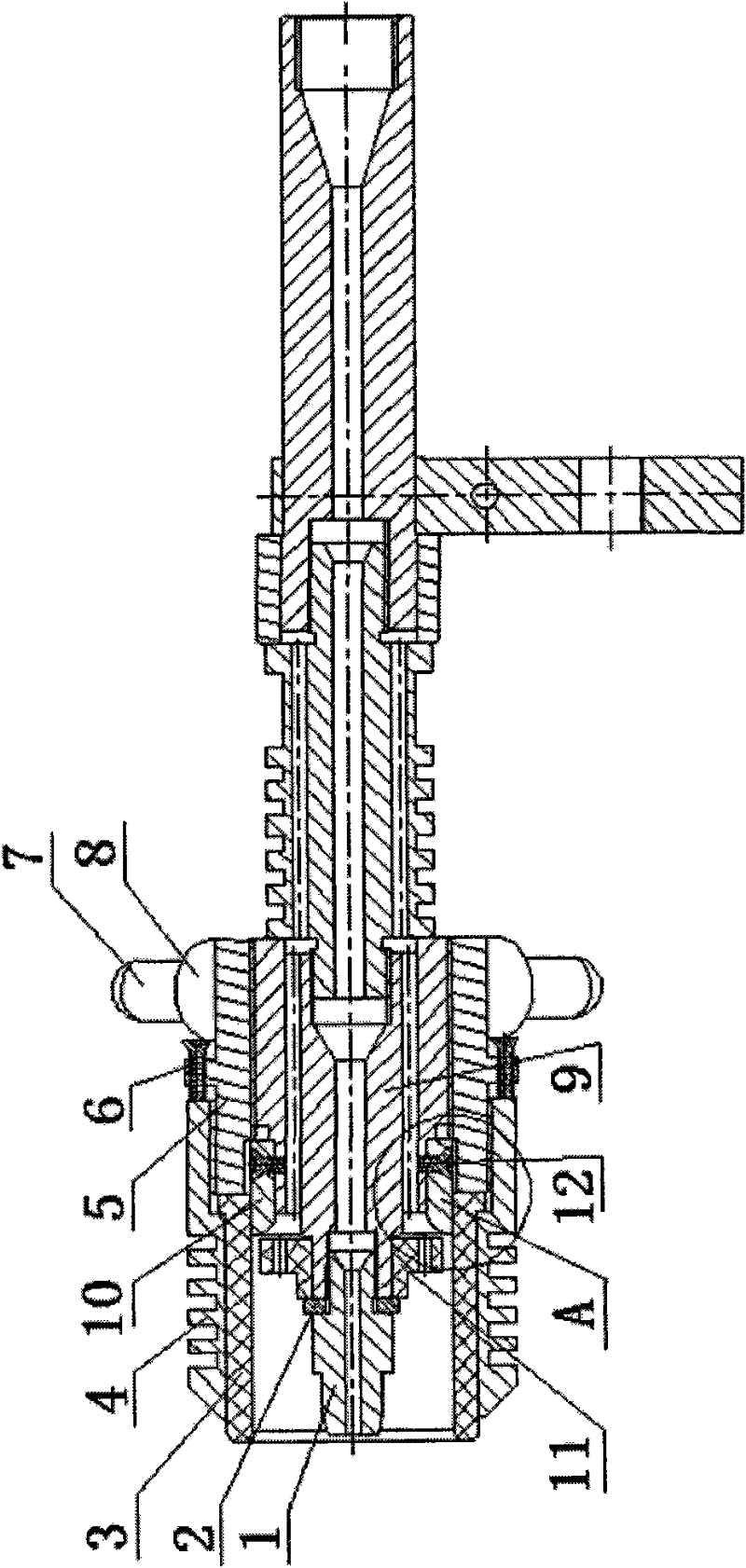

Holster of argon arc welding gun special for narrow gaps and deep grooves

InactiveCN109986184AAvoid bakingContinuous free operationSupport devices with shieldingThermal insulationNarrow gap

The invention provides a holster of an argon arc welding gun special for narrow gaps and deep grooves, and belongs to the field of welding. The holster of the argon arc welding gun special for the narrow gaps and the deep grooves comprises a sleeve, a gun grip, a baffle, two nuts, bolts and a protective device, the gun grip is welded vertically to the tail end of the sleeve, the baffle is welded vertically to the front end of the sleeve, and the baffle and the gun grip are parallel to each other, the protective device sleeves the outer side of the baffle, holes are evenly formed in the top endof the sleeve, the two nuts are arranged at the top end of the sleeve, and the nuts are matched with the bolts to fix a welding gun. According to the holster of the argon arc welding gun special forthe narrow gaps and the deep grooves, an original straight pen gun is simply assembled, thus the argon arc welding gun holster and the original straight pen gun are integrated into one, by changing the way of holding the gun, and additionally arranging the thermal insulation protective device on the gun grip, baking of hands of welders by the high temperature can be effectively avoided, thus the welders can operate continuously and freely, high-quality weld joints are easy to obtain, the investment is low, but the big problems in the production practice can be solved.

Owner:HARBIN BOILER

Tencel Bamboo Fiber Shirt Fabric Production Equipment

ActiveCN112484425BImprove drying efficiencyAvoid concentrationDrying gas arrangementsDrying chambers/containersFiberAgricultural engineering

A production device for Tencel bamboo fiber shirting fabric belongs to the technical field of textile equipment; a fixed rod is provided on the outer circular wall of the sleeve shaft, a rotating hole is opened on the outer wall of the fixed rod, a fixed block is fixedly installed on the outer wall of the fixed rod, and a fixed block is fixed on the outer wall of the fixed block. An extension plate is fixedly installed on the top, and a wind-resisting plate is fixedly installed on the upper wall of the extension plate. The dried cloth is fixed inside the dryer shell through the fixing clip. The cloth is not flattened. The motor is connected with the external power supply equipment, and the motor drives the magnet. Once rotated, when the first magnet rotates to correspond to the position of the through hole, the first magnet and the second magnet repel each other, at this time, the connecting frame rotates upward under the repulsive force of the first magnet and the second magnet, and the scraper follows the upward rotation of the connecting frame to move cloth, and then the scraper rotates downward under the force of the tension spring, and the scraper moves up and down inside the shell of the dryer and constantly pushes against the cloth to drive the cloth to vibrate to shake off the moisture in the cloth to speed up the drying of the cloth dry efficiency.

Owner:浙江贤烨新材料科技有限公司

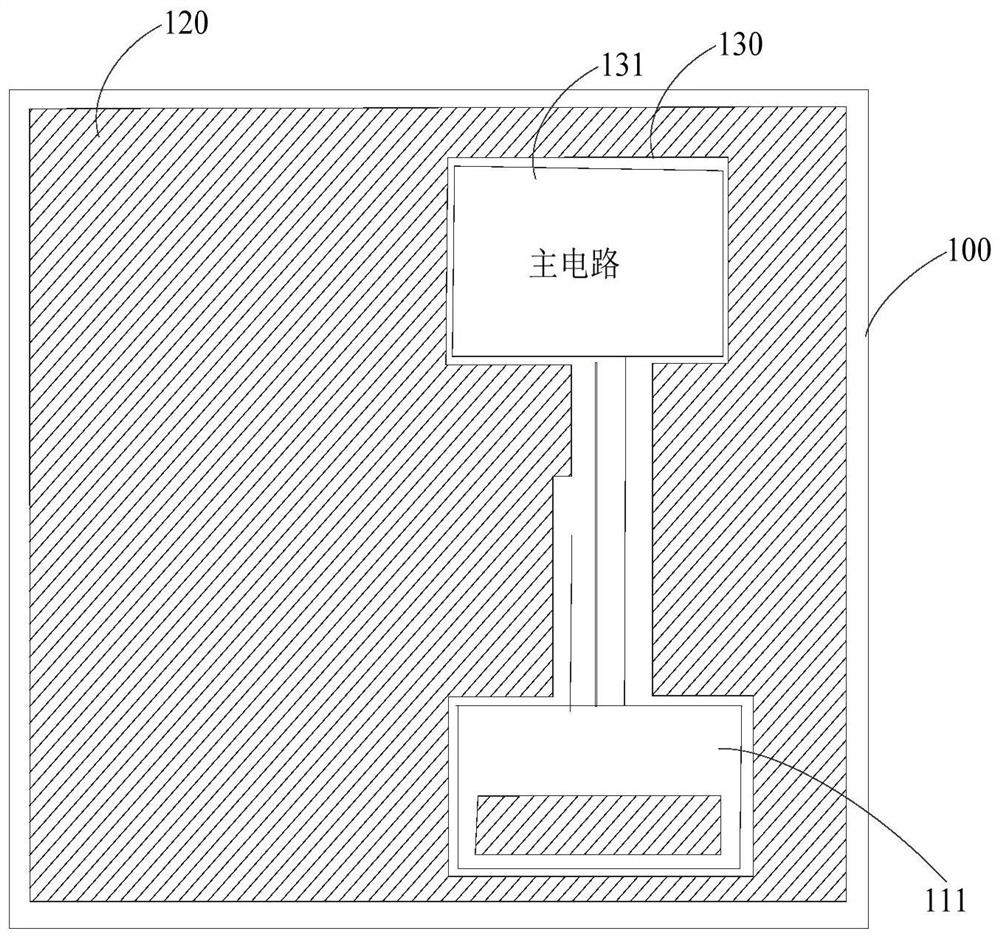

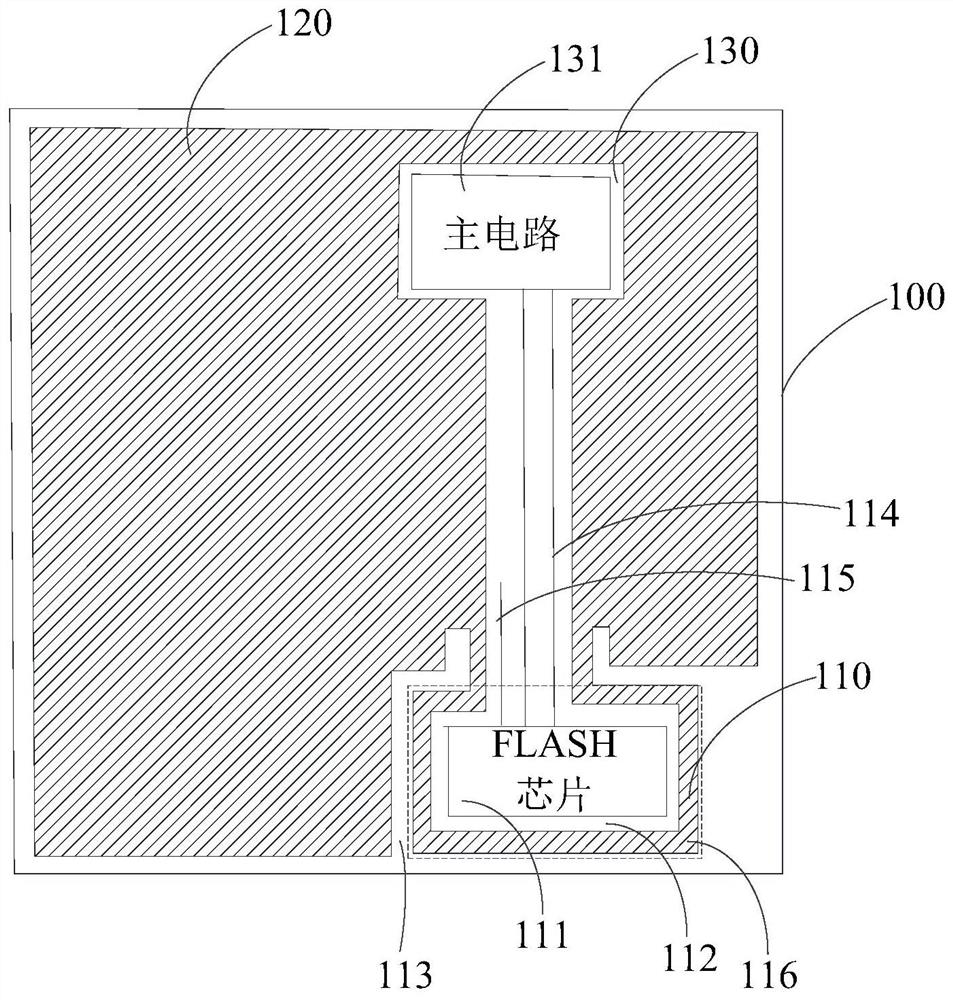

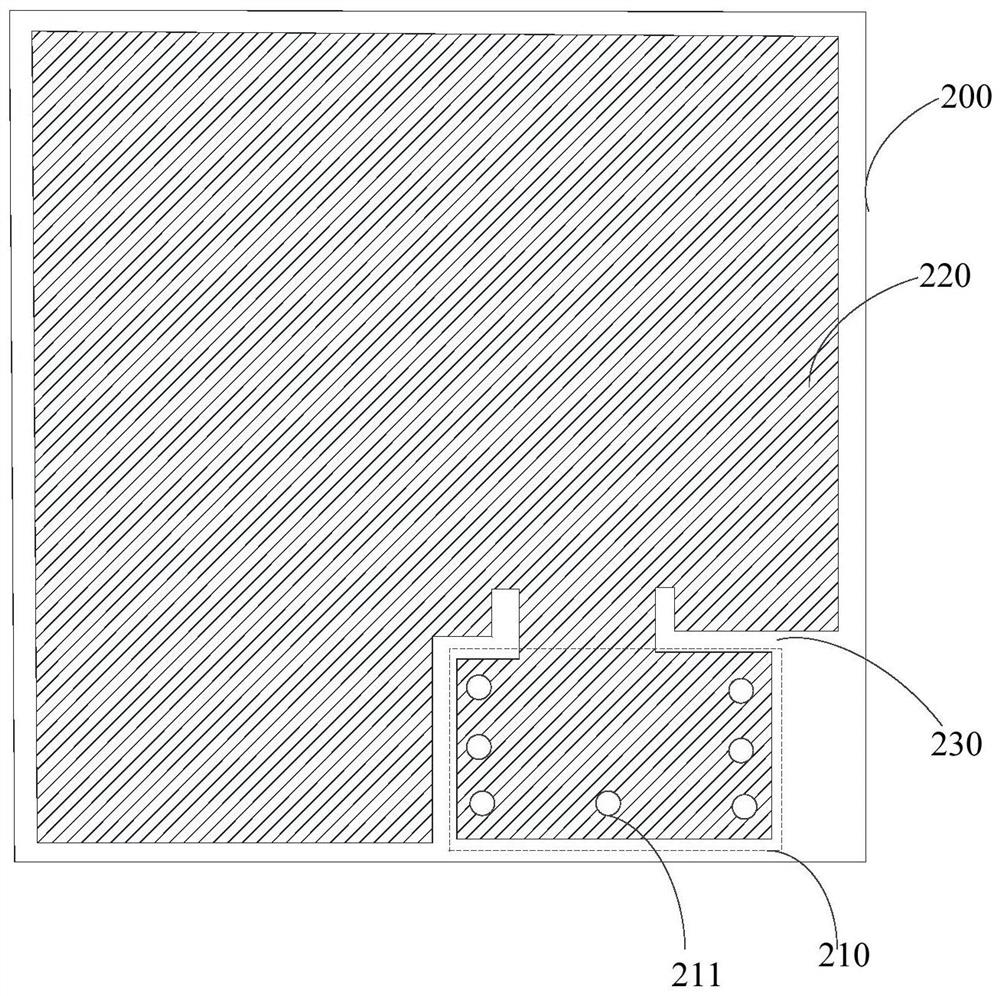

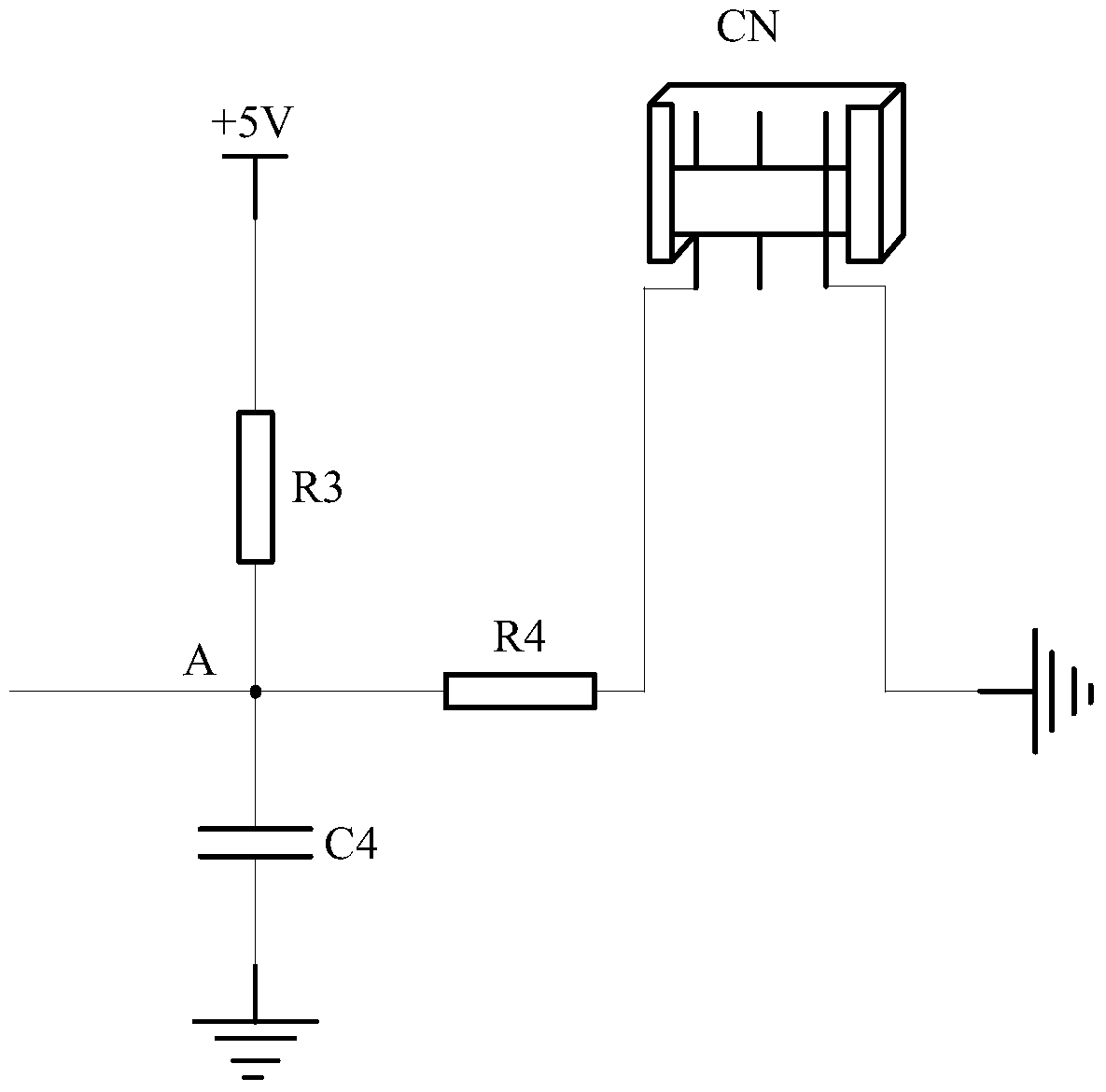

Main board of router and router

PendingCN113438556ALittle thermal impactReduce the temperatureModifications by conduction heat transferSelection arrangementsComputer hardwareHemt circuits

The invention provides a main board of a router and the router. The main board of the router comprises a FLASH chip main circuit and a multi-layer PCB for bearing the main circuit and the FLASH chip, the main circuit and the FLASH chip are oppositely arranged on the PCB at a preset interval, baking of a heat source is prevented, meanwhile, the FLASH chip and the main circuit are arranged on different arrangement areas respectively, The FLASH chip and the GND network are isolated through the first isolation groove, heat transfer of the GND network is reduced, heat influence of a heat source on the FLASH chip is reduced and the temperature of the FLASH chip is reduced by arranging the isolation groove and keeping away from the heat source, meanwhile, a cooling fin does not need to be arranged or a vehicle-level material does not need to be changed, and the design cost is reduced.

Owner:SHENZHEN GONGJIN ELECTRONICS CO LTD

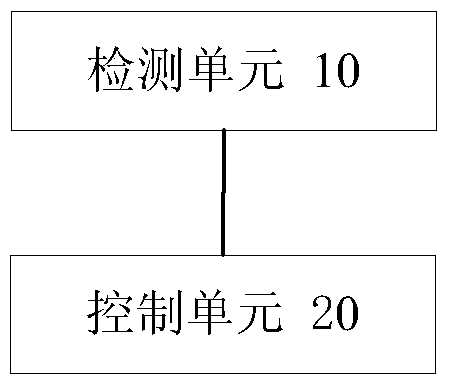

Protection method and device for air-conditioning wind deflector

ActiveCN104075414BAvoid bakingSolve the fragileMechanical apparatusSpace heating and ventilation safety systemsAir conditioningAerospace engineering

Disclosed is a protection method used for an air-conditioning air guide plate, comprising: detecting whether an abnormality has occurred in the position of an air guide plate for air-conditioning; and if it is detected that an abnormality has occurred in the position of an air guide plate for air-conditioning, controlling correction of the position of the air guide plate for air-conditioning. Further disclosed is a protection apparatus used for an air-conditioning air guide plate. The method and the apparatus solve the problem of air guide plates being easily damaged.

Owner:GREE ELECTRIC APPLIANCES INC

Efficient wood drying device

InactiveCN112146388AReasonable structureImprove efficiencyDrying gas arrangementsDrying chambers/containersWood dryingElectric machinery

The invention discloses an efficient wood drying device. The efficient wood drying device comprises a drying cavity, wherein a drying frame is arranged in the drying cavity, walking wheels are fixed to the bottom face of the drying frame, a plurality of parallel drying bearing plates are arranged on the drying frame, an exhaust pipe is fixed to the drying cavity, and a condenser is connected to the exhaust pipe. At least two parallel strip-shaped grooves are formed in the top faces of the drying bearing plates, warping plates are arranged in the strip-shaped grooves, the middles of the warpingplates are connected into the strip-shaped grooves through pin shafts, supporting plates are fixed to the top ends of the warping plates, the bottom ends of the warping plates are connected through synchronous supporting rods, and a winding motor is fixed to the bottom of the drying frame; and an inhaul cable is arranged between a main shaft of the winding motor and the bottom ends of the warpingplates, heating cavities are fixed in the drying bearing plates, and electric heating pipes are fixed in each heating cavity. According to the efficient wood drying device, the structural arrangementis reasonable, the situation that during drying, the bottom face of wood cannot be dried or is damaged due to contact is avoided, the drying efficiency and the drying effect can be better improved, and the efficient wood drying device is high in applicability and good in practicability.

Owner:徐艳

Airflow heating electronic cigarette

The invention discloses an airflow heating type electronic cigarette. The electronic cigarette can comprise a filtering assembly, a tobacco pot assembly, a heating assembly and a battery assembly. Fluid is placed in the filtering assembly to filter smoke; the tobacco pot assembly is connected to the filtering assembly, and a heated medium is placed in the tobacco pot assembly; the heating assembly is connected to the tobacco pot assembly and used for generating heating airflow to heat the heated medium in the tobacco pot assembly; the battery assembly is connected to the heating assembly to supply power to the heating assembly.

Owner:SHENZHEN YOOTECH CO LTD

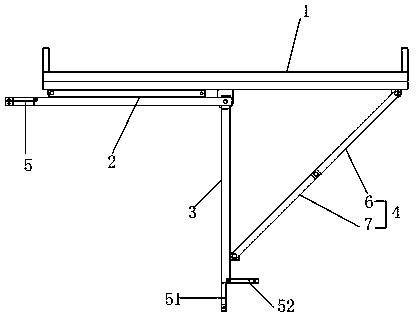

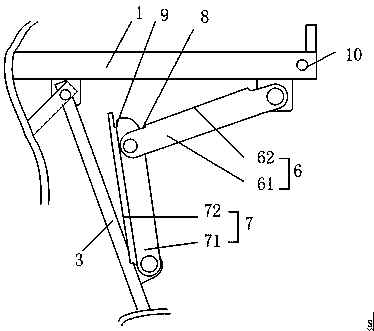

Multifunctional airing device

InactiveCN109931757AAvoid dustKeep the flavorDrying chambers/containersDrying solid materialsEngineeringDried fruit

The invention relates a multifunctional airing device. The multifunctional airing device comprises a body and a support, wherein the body is arranged on the support, the support comprises a supportingplate and a connecting plate, one end of the supporting plate is hinged to the body, and the other end of the supporting plate is provided with a hoop used for being fixed with a heating radiator; one end of the connecting plate is hinged to the edge of the body, the other end of the connecting plate is hinged to the other end of the supporting plate, the connecting plate is formed by hinging a first connecting plate and a second connecting plate, a limiting assembly is arranged between the first connecting plate and the second connecting plate, so that 180 degrees can be rotated between thefirst connecting plate and the second connecting plate. The airing rack can be fixed on a cross rod for airing, and can also be connected with the heating radiator for drying of tea leaves and dried fruit, the support can be folded, and the multifunctional airing device has the characteristics of being convenient to use and reasonable in structure.

Owner:XIAN QUALITY INFORMATION TECH

Novel self-rotating large-current MAG (Magnetic) welding composite nozzle welding gun for removing slag and slag removing method thereof

ActiveCN101829839BImprove cooling effectNo risk of short circuitElectrode accessoriesWelding accessoriesSlag (welding)Engineering

The invention provides a self-rotating large-current MAG (Magnetic) welding composite nozzle welding gun for removing slag and a slag removing method thereof. The invention aims at solving the slag removal difficulty of the welding gun in large-current MAG welding process and further optimizing a nozzle structure. The invention mainly comprises a welding gun structure which can remove welding spattering slag in a composite nozzle in a self-rotating way as well as a self-rotating slag-removing method of the welding gun. The welding gun structure and the self-rotating slag-removing method are suitable for thick wire large-current MAG welding.

Owner:HARBIN WELDING INST LTD

Compensation moving dolly for continuous casting steel moving machine

The invention discloses a compensation moving dolly for a continuous casting steel moving machine, comprising a frame, a joist fixed on the frame and four wheels installed at two ends of the frame. The lower parts of two ends of the frame are fixedly provided with two guide boxes; each guide box is internally provided with a disc spring group, a guide rod and a guide plate; the disc spring groups and the guide plate are connected in series by the guide rod; the top end of the guide rod extends out of the guide boxes and is connected with a rope ring; the end part of the guide box is provided with a pressure plate which supports the guide rod; and the frame is fixedly provided with an upper heat prevention plate and a lower heat prevention plate. The invention is a compensation moving dolly for a continuous casting steel moving machine, which is novel in structure and symmetrically arranged, and has good performances such as heat radiation prevention, adjustable steel cable tensile force, disc spring buffering, large length compensation of steel cable close ring and the like.

Owner:WISDRI ENG & RES INC LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com