Tool arranged on ring rolling machine for automatically rolling wind power L-shaped flange and method of tool

A wind power, L-shaped technology, applied in the direction of mechanical measuring devices, adopting mechanical devices, measuring devices, etc., to achieve the effect of convenient measurement work, saving working time and convenient maintenance work

Inactive Publication Date: 2022-06-10

SHANXI TIANBAO GRP CO LTD

View PDF0 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] The purpose of the present invention is to provide a tooling and method for automatically rolling into L-shaped flange ring rolling machine for wind power and its method, so as to solve the problems in the above background technology. Some of the tooling on the ring rolling machine is difficult to use, which makes it inconvenient for the user to operate and use. When measuring the convex ring of the L-shaped flange, the user needs to wait for it to cool down before measuring. Further, the user's working time is wasted, the user's work efficiency is low, and the product's construction period is further affected. This solution is convenient for the user's operation, and the measurement work can be carried out when the workpiece is high temperature, so that it can be carried out at any time according to the measurement results. Change, no need for the user to cool down the workpiece before measurement, saving a lot of working time for the user, greatly improving the production cycle of the workpiece, the user does not need to be close to the measurement, avoiding the user being baked by high temperature, and further improving the safety of the user when measuring

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

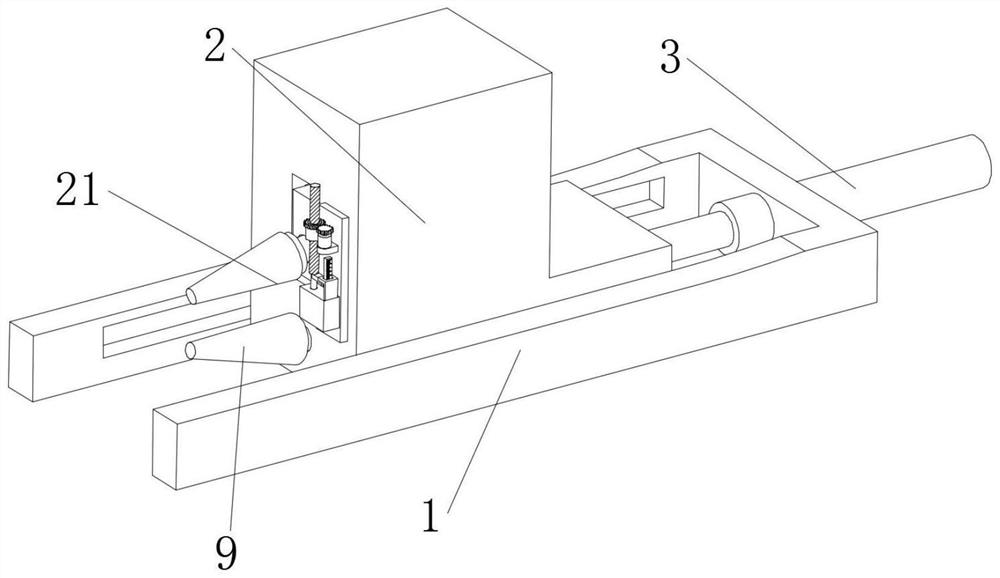

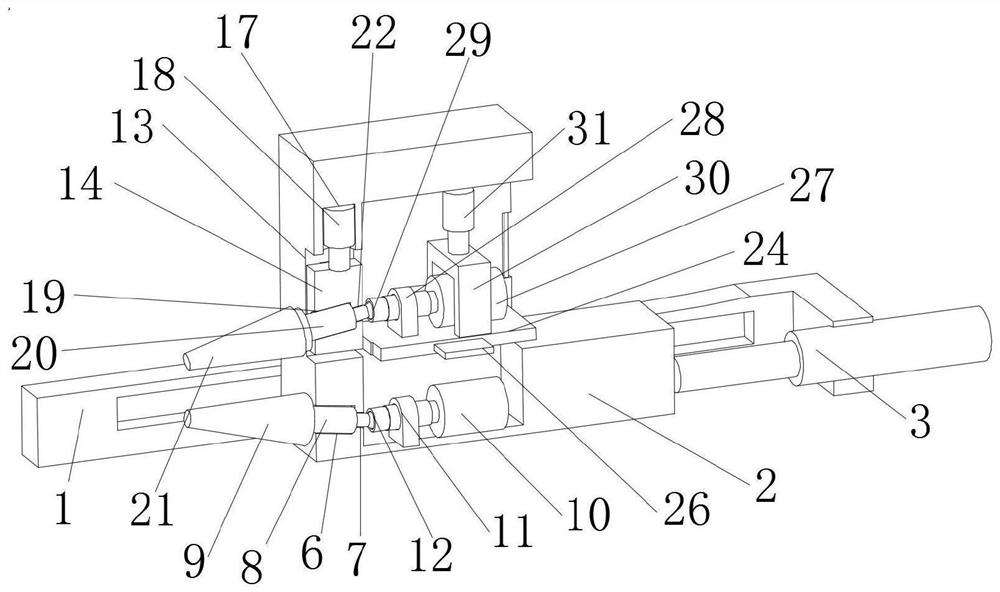

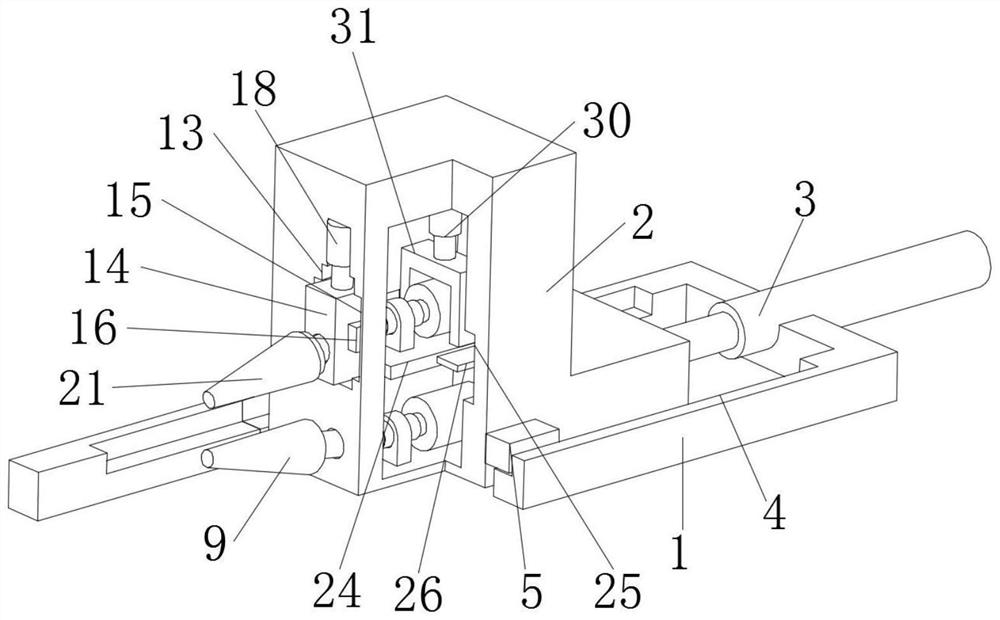

The invention relates to the technical field of wind power L-shaped flange machining, in particular to a tool arranged on a ring rolling machine for automatically rolling wind power L-shaped flanges and a method thereof.The tool comprises a moving table and a measuring mechanism, a moving part is arranged in the moving table, and a first hydraulic rod is arranged at one end of the moving table; a first connecting groove is formed in the inner wall of one end of the first rotating groove, a first rotating rod is rotatably connected to the interior of the first rotating groove, a first conical rod is fixedly connected to one end of the first rotating rod, and a first servo motor is arranged on the inner wall of the bottom end of the moving part. The device is simple and convenient to operate and convenient to maintain, and can perform measurement work when the workpiece is at high temperature, so that change can be performed at any time according to a measurement result, a user does not need to perform measurement after cooling the workpiece, a large amount of working time of the user is saved, the production cycle of the workpiece is greatly prolonged, the user does not need to get close to measure, and the user is prevented from being baked by high temperature; and the measurement safety of the user is further improved.

Description

technical field [0001] The invention relates to the technical field of wind power L-shaped flange processing, in particular to a tooling and a method for automatically forming a wind power L-shaped flange ring rolling machine. Background technique [0002] Simply put, the wind power flange is the flange of the wind turbine. The wind power flange is also called the wind tower flange. The L-shaped wind power flange means that the section of the wind power flange is L-shaped. The processing of wind turbine flanges can be processed and formed by ring rolling machines. Ring rolling (also known as ring rolling, ring rolling expansion, hole expansion, ring rolling) Hole reaming machine) makes the ring produce continuous local plastic deformation, and then realizes the plastic processing technology of reducing wall thickness, expanding diameter and forming cross-sectional profile; The tooling on some existing ring rolling machines is difficult to get started in use, which makes it...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G01B5/06G01B5/18G01B5/00B21H1/06

CPCG01B5/061G01B5/18G01B5/0002B21H1/06

Inventor 胡大为闫志龙刘俊杰乔勇强闫宇王鹏曹晋张雁玲

Owner SHANXI TIANBAO GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com