Efficient wood drying device

A drying device and wood technology, applied in drying, drying machines, heating devices, etc., can solve the problems affecting drying efficiency and drying effect, applicability and practicability limitations, and the bottom surface of wood is damaged. , to achieve the effect of improving the drying effect, good practicability and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

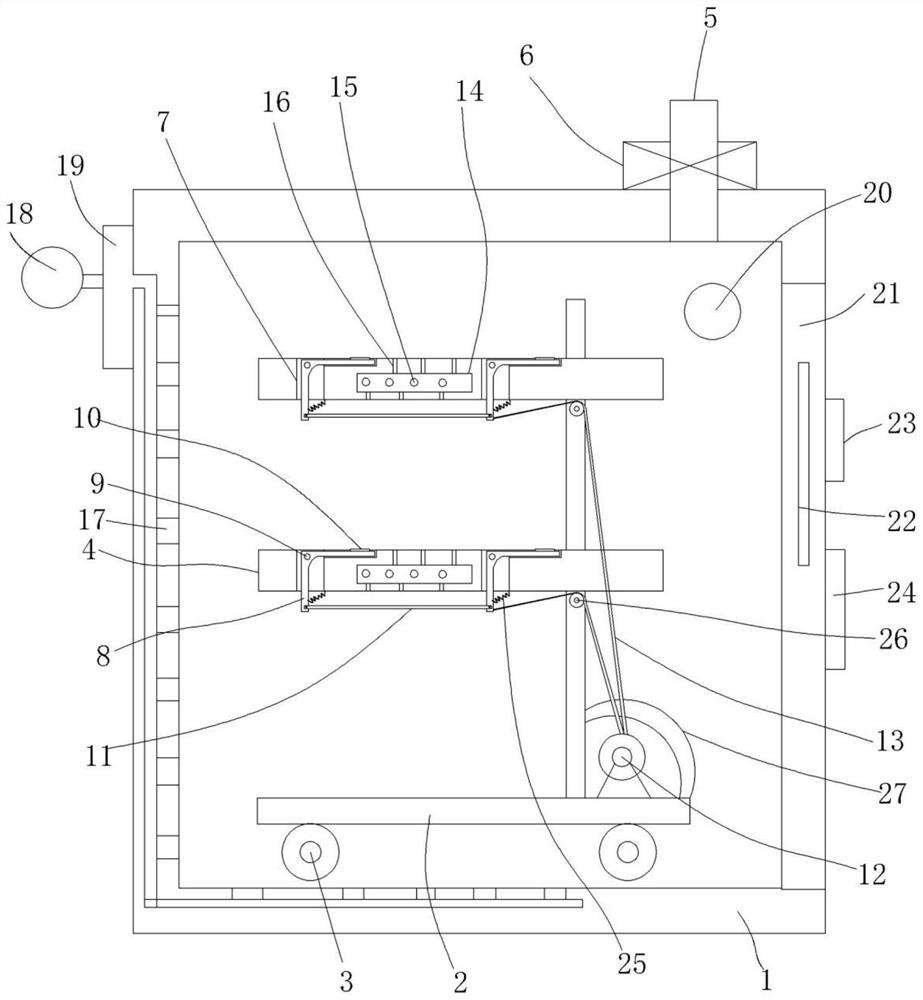

[0016] figure 1 A specific embodiment of the invention is shown in which figure 1 It is a structural schematic diagram of the present invention.

[0017] See figure 1 , a high-efficiency wood drying device, including a drying chamber 1, a drying rack 2 is arranged in the drying chamber, a walking wheel 3 is fixed on the bottom surface of the drying rack, and several A parallel drying carrier plate 4, an exhaust pipe 5 is fixed on the drying chamber, and a condenser 6 is connected to the exhaust pipe. In this embodiment, the condenser is a technical knowledge structure of the prior art , the top surface of the drying carrier plate is provided with at least two parallel strip-shaped grooves 7, and at least three strip-shaped grooves are provided, and wood of different lengths can be placed, thereby greatly improving the drying range. A seesaw 8 is arranged in the strip groove, the middle part of the seesaw is connected in the strip groove by a pin 9, a support plate 10 is fix...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com