Tencel Bamboo Fiber Shirt Fabric Production Equipment

A production device, the technology of Tencel Bamboo, is applied in the direction of drying solid materials, drying gas arrangement, non-progressive dryer, etc., which can solve the problems of stacking together and slow drying of cloth.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

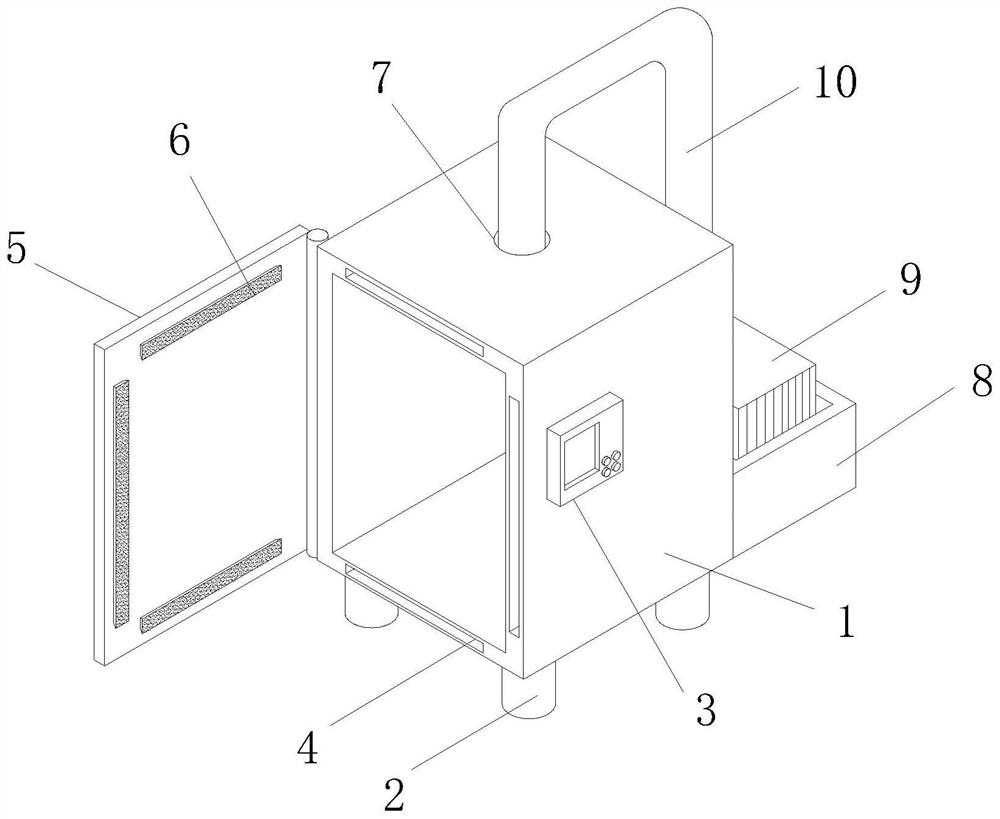

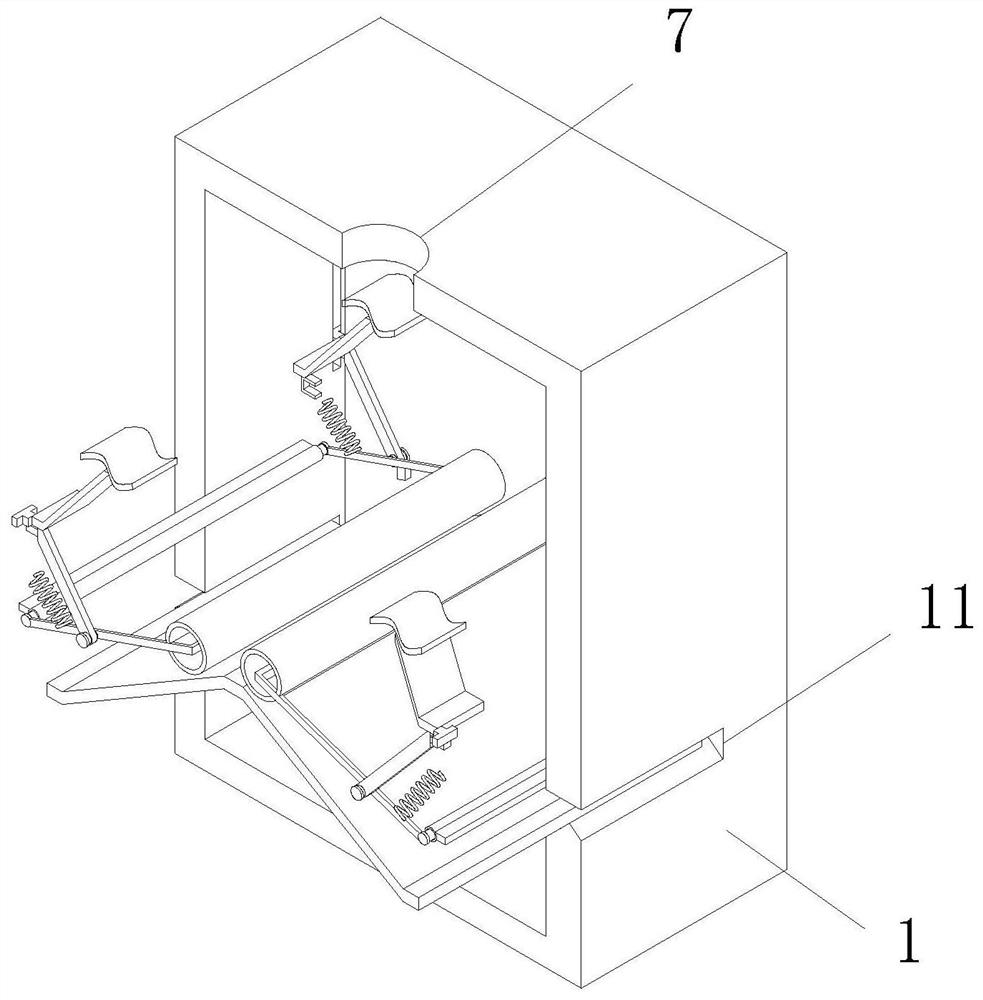

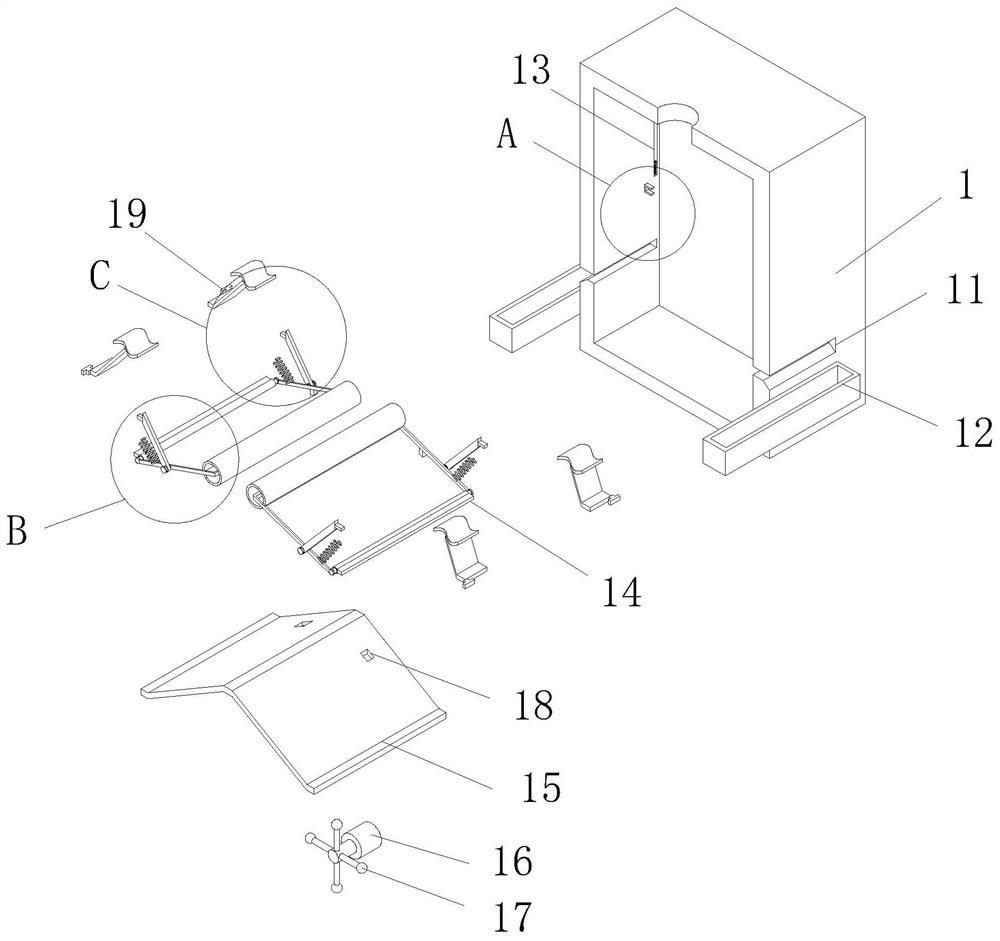

[0031] Example: The production device of Tencel bamboo fiber shirt fabric, such as Figure 1-Figure 6As shown, it includes a dryer shell 1, the dryer shell 1 is a rectangular hollow structure, the four corners of the lower wall of the dryer shell 1 are fixedly installed with support legs 2, and the support legs 2 are cylindrical structures, drying The right wall surface of the machine casing 1 is provided with a controller 3. The controller 3 is an existing structure, which will not be repeated here. The rear wall surface of the dryer casing 1 is provided with three card slots 4. The left wall surface of the machine casing 1 is provided with a cover plate 5. The cover plate 5 is of a rectangular structure. The cover plate 5 is movably connected with the dryer casing 1 through hinges. 4. The card pads 6 are clamped together. The cross section of the card pad 6 is a trapezoid structure. The card pad 6 is made of rubber. The front wall surface of the dryer shell 1 is fixedly ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com