Holster of argon arc welding gun special for narrow gaps and deep grooves

A technology of argon arc welding torch and deep bevel, which is applied in the field of special argon arc welding torch holsters for narrow gap and deep bevel, which can solve problems such as easy cracks, unsightly weld formation, and unguaranteed weld quality, and achieve little effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

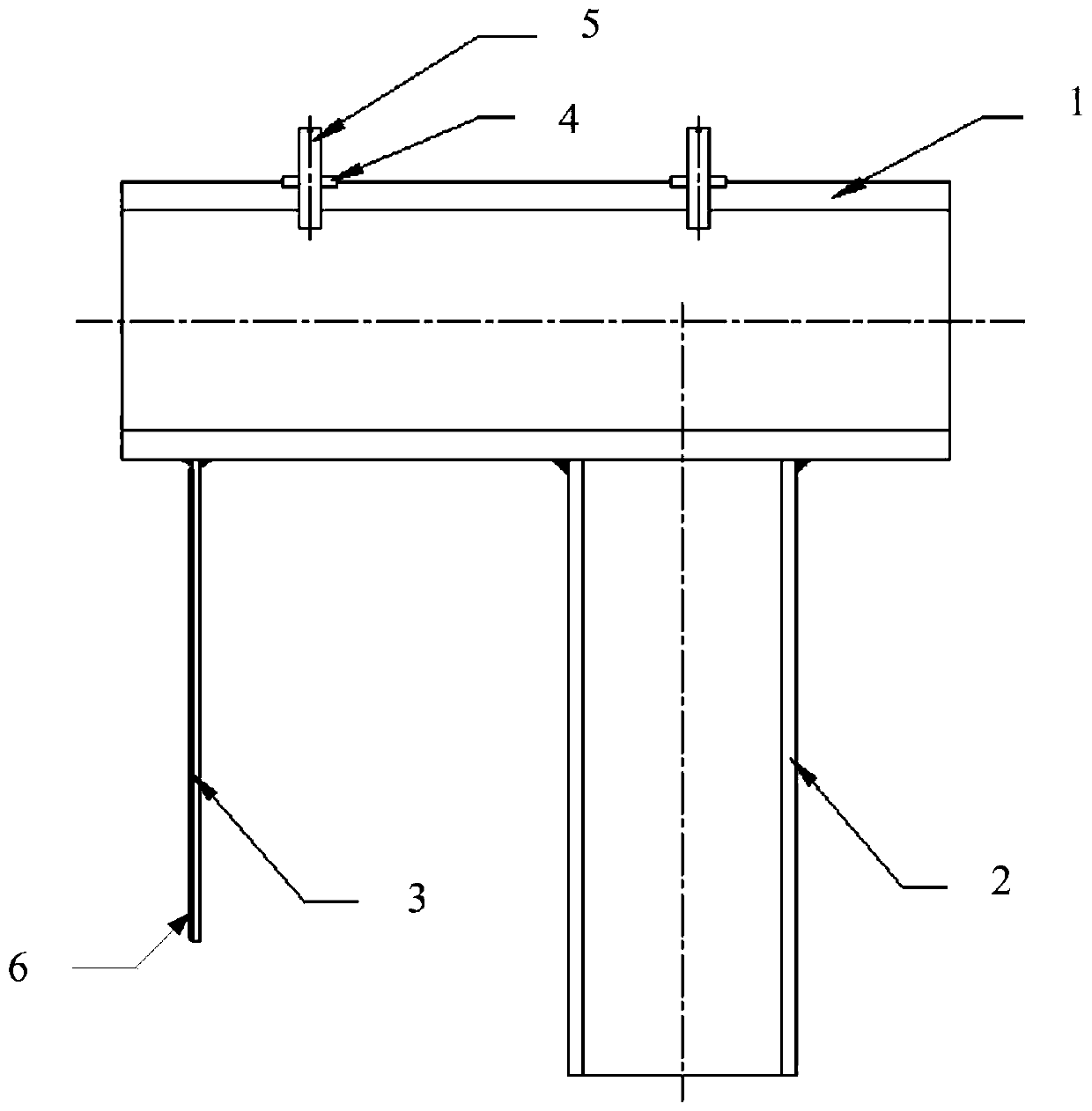

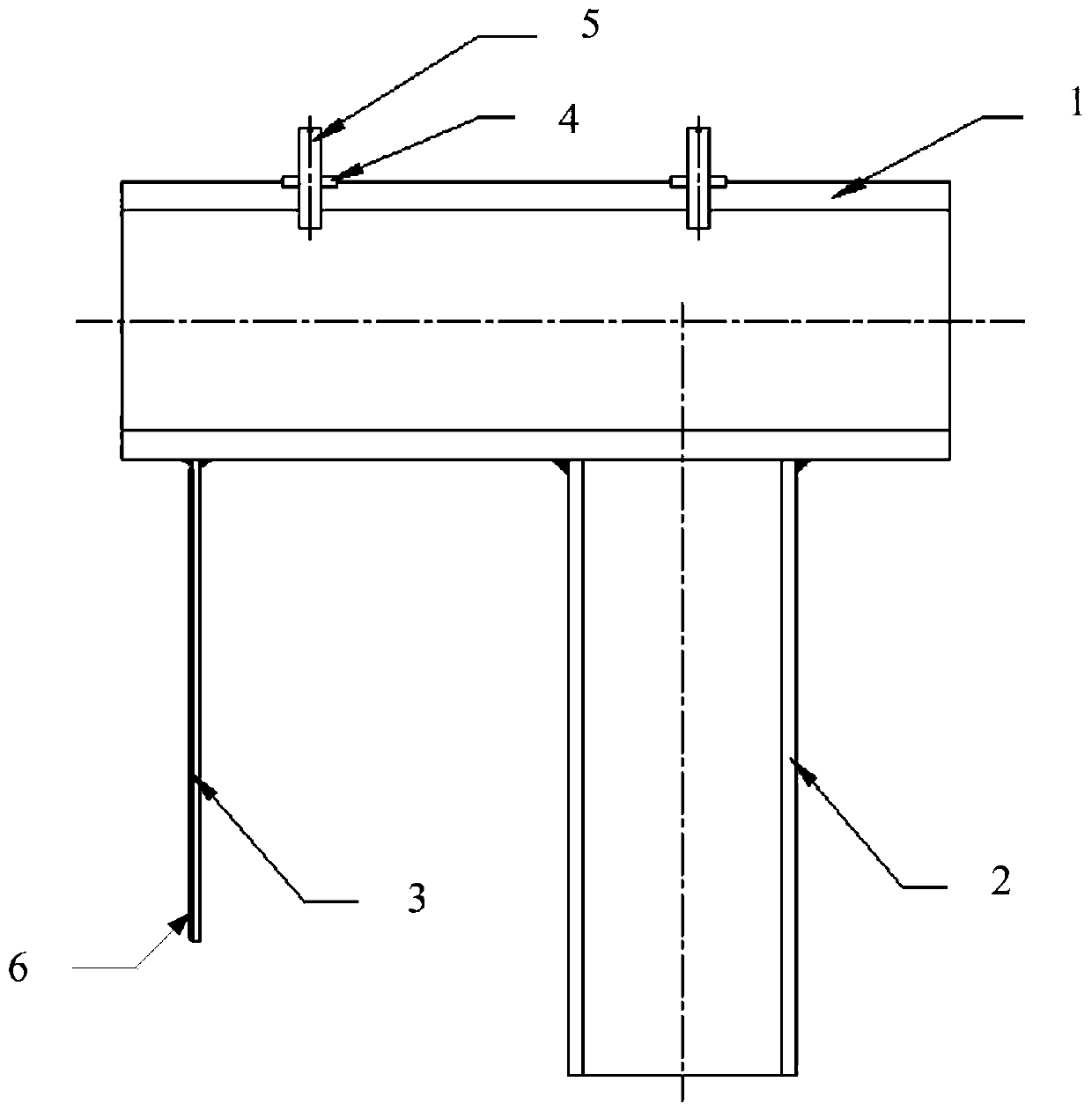

[0016] Embodiment one: if figure 1 As shown, the special argon arc welding gun holster for narrow gap and deep groove involved in this embodiment includes sleeve, gun handle, baffle plate, nut, bolt and protective device. The gun handle is welded vertically on the tail end of the sleeve. The plate is vertically welded on the front end of the sleeve, and the baffle and the gun handle are parallel to each other. The outer side of the baffle is covered with a protective device. The top of the sleeve is evenly opened and two nuts are arranged, and the nuts and bolts are matched to the welding torch. fixed.

[0017] Special argon arc welding gun holster for narrow gap and deep groove, the baffle is a metal plate, the middle of the baffle is folded inward to form an obtuse angle, the middle of the baffle is welded on the sleeve and the obtuse angle of the baffle is facing the gun Bundle.

[0018] Special argon arc welding torch holster for narrow gap and deep groove, the sleeve is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com