Welding and radiating turntable

A turntable and cooling fan technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of time-consuming shaping process, low efficiency of segmented welding, scrapping, etc., to facilitate heat dissipation, improve heat dissipation effect, Flexible and accurate operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

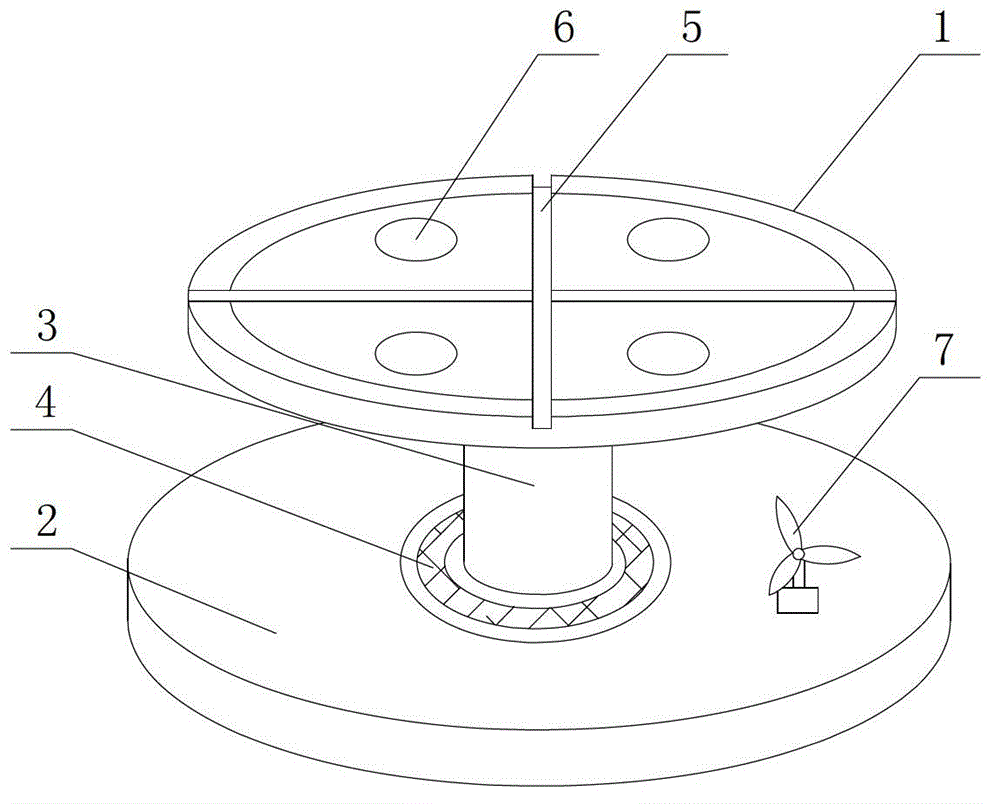

[0012] Such as figure 1 As shown, the welding heat-dissipating turntable according to the embodiment of the present invention includes a rotating platform 1 and a platform bottom plate 2. The rotating platform 1 is in the shape of a disc, and the center of the rotating platform 1 is connected and fixed with a rotating shaft 3, and the rotating shaft 3 is installed A bearing 4 is provided on the platform bottom plate 2 and between the rotating shaft 3 and the platform bottom plate 2; the rotary platform 1 is provided with a cross groove 5, and the center of the cross groove 5 is located in the center of the rotary platform 1. The cross groove 5 divides the rotating platform into four equal sectors, and a vent 6 is provided at the center of each sector.

[0013] A circumferential angle is engraved on the rotating platform 1 along the circumference.

[0014] A cooling fan 7 is provided on the platform bottom plate 2, and the wind direction of the cooling fan 7 points to the turning p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com