Upright packaging machine

A vertical packaging machine and frame technology, applied in the direction of packaging, transportation packaging, multiple packages, etc., can solve the problems of uneven sealing, large working noise and vibration, long sealing transition time, etc., to solve the problem of uneven sealing The effect of leveling, improving work efficiency and improving bag making efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

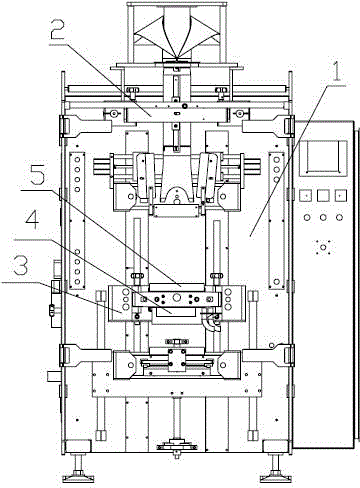

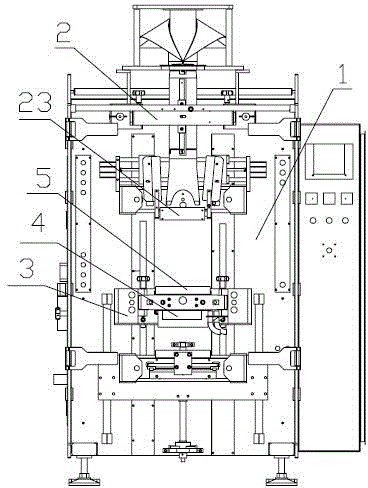

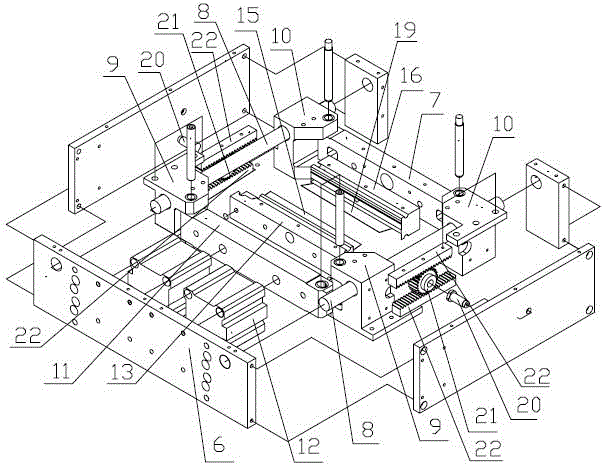

[0035]As a preferred embodiment of the present invention, the vertical packaging machine includes a frame 1, a film holding device, an unwinding device, a blanking device, a collar forming device and a longitudinal sealing device 2, and the collar forming device is arranged on the blanking device. The outer side of the upper part, the M-shaped side forming device connected to the lower outer side of the blanking device, the traction device located under the M-shaped side forming device and the horizontal sealing device located under the traction device and fixedly connected with the inner wall of the frame. The traction frame 3 slidingly connected to the inner wall of the frame 1, the traction cylinder 4 fixed on the traction frame 3, the two clamping blocks 5 driven by the traction cylinder 4, the horizontal sealing device includes a horizontal sealing frame 6, a front horizontal sealing seat 7, Guide shafts 8 fixed on the front and rear inner walls of the horizontal seal fram...

Embodiment 2

[0038] As the best embodiment of the present invention, the vertical packaging machine includes a frame 1, a film supporting device, an unwinding device, a blanking device, a collar forming device and a longitudinal sealing device 2, and the collar forming device is arranged on the upper part of the blanking device. Outer side, the M-shaped side forming device connected to the outer side of the lower part of the blanking device, the traction device located under the M-shaped side forming device and the horizontal sealing device located under the traction device and slidingly connected to the inner wall of the frame. 1 The traction frame 3 slidingly connected to the inner wall, the traction cylinder 4 fixed on the traction frame 3, the two clamping blocks 5 driven by the traction cylinder 4, the horizontal sealing device includes a horizontal sealing frame 6, a front horizontal sealing seat 7, a fixed The guide shafts 8 on the front and rear inner walls of the horizontal seal fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com