Inverted-triangular steel tube intersected spatial truss and assembly method thereof

A three-dimensional truss and triangular technology, applied in the field of support frame, can solve the problems of inconvenient cutting and assembling operations, unreasonable three-dimensional truss structure intersecting with inverted triangular steel pipes, etc., and achieve the effects of convenient construction, economical use of materials and cost saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

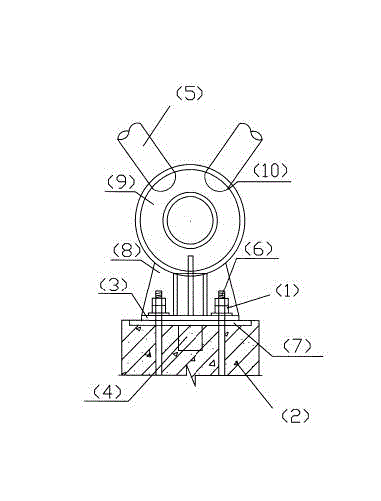

[0016] An inverted triangular steel pipe intersecting three-dimensional truss, comprising a concrete support 2, a pre-embedded steel plate 7 is arranged on the top surface of the concrete support 2, and a pre-embedded steel plate in the concrete support 2 is welded under the pre-embedded steel plate 7 The shear steel pipe 4 is fixedly welded with a cross-shaped support rib frame 8 on the bottom plate 3 of the hollow ball support. Hollow ball support base plate 3 is fixedly connected together, and hollow ball 9 is welded on the arc-shaped top surface of cross-shaped supporting rib frame 8, and a pair of hollow ball node holes 10 are arranged on the spherical surface of hollow ball 9, two hollow balls The ball joint hole 10 is symmetrical with the straight line passing through the center point of the hollow ball 9 and perpendicular to the embedded steel plate 7. In the hollow ball joint hole 10, the steel pipe 5 forming the inverted triangle side is fixedly welded, forming an inv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com