Hybrid grating on-line temperature measurement type all-fiber current transformer and current detection method thereof

A current transformer and current detection technology, applied in the direction of measuring current/voltage, measuring electrical variables, voltage/current isolation, etc., can solve the problems of limiting the application of fiber-optic current transformers, the stability of current detection and the influence of measurement accuracy, etc. To achieve the effect of saving manpower and material resources and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] A specific embodiment of the present invention will be briefly described below in conjunction with the accompanying drawings.

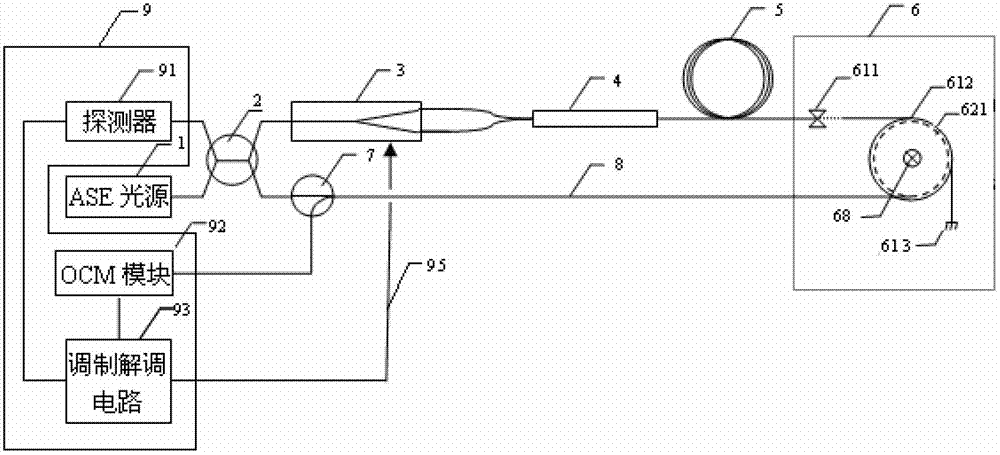

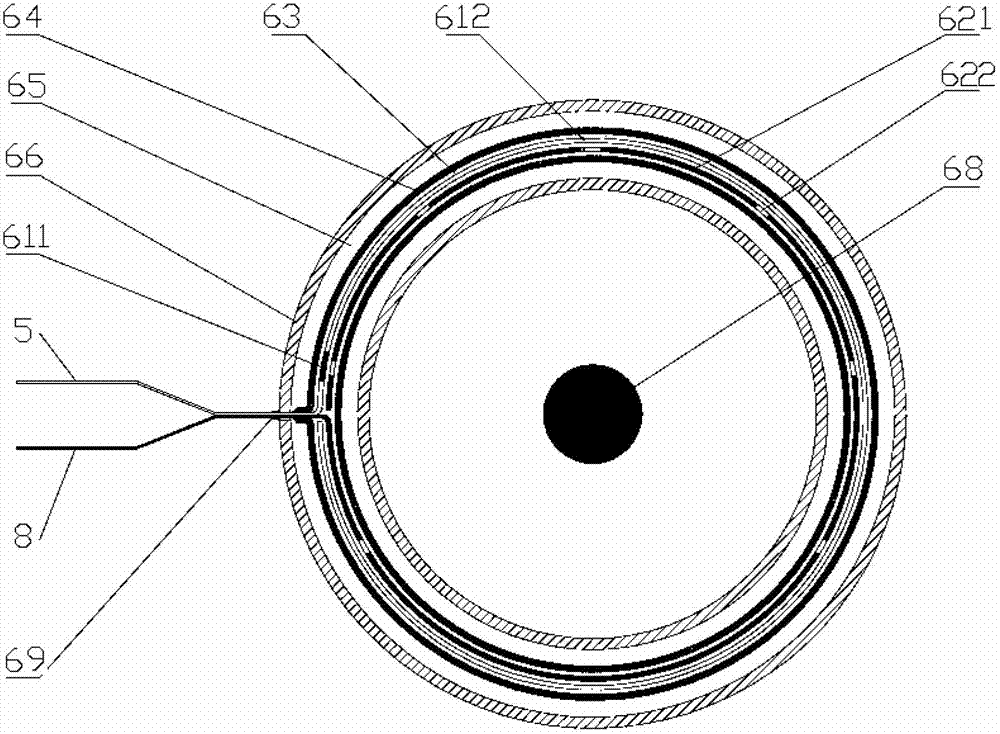

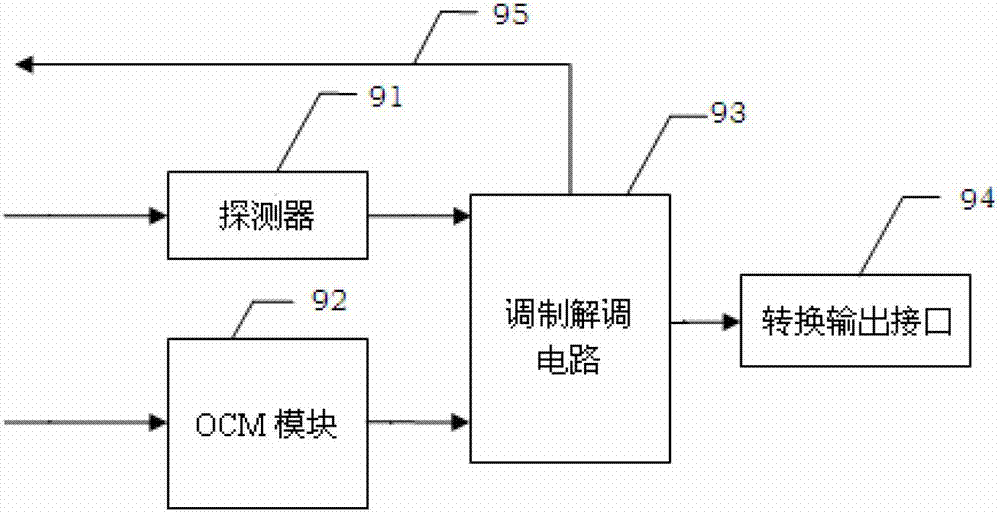

[0029] Such as figure 1 , a hybrid grating on-line temperature measurement all-fiber current transformer, including a current detection optical circuit and a temperature detection optical circuit, and the current detection optical circuit includes a sequentially connected light source 1, a polarization maintaining coupler 2, a phase modulator 3, and a polarization beam combiner 4. The polarization-maintaining transmission fiber 5 and the sensor head 6, the temperature detection optical path includes a sequentially connected light source 1, a polarization-maintaining coupler 2, an optical circulator 7, a single-mode transmission fiber 8 and a sensor head 6, the light source 1, The polarization maintaining coupler 2 and the sensor head 6 are shared by two optical paths, and the two optical paths also include a shared photoelectric conversion modu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com