Hydrocarbon oil dewaxing experimental instrument and experimental method thereof

An experimental instrument and dewaxing technology, applied in experimental instruments and the field of experiments, can solve problems such as adverse effects on the physical health of experimental personnel, and achieve the effects of ensuring solvent temperature and simple control process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

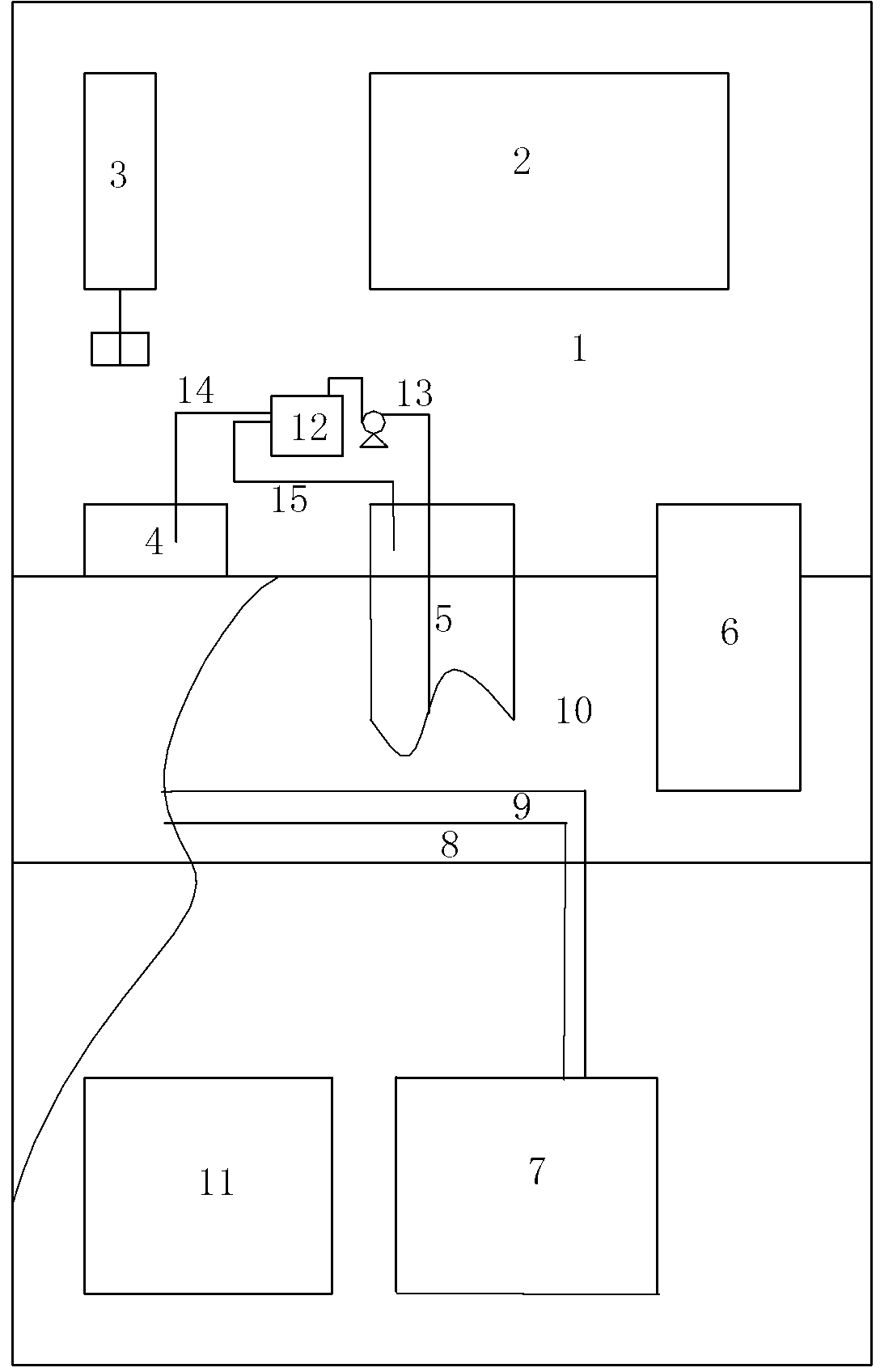

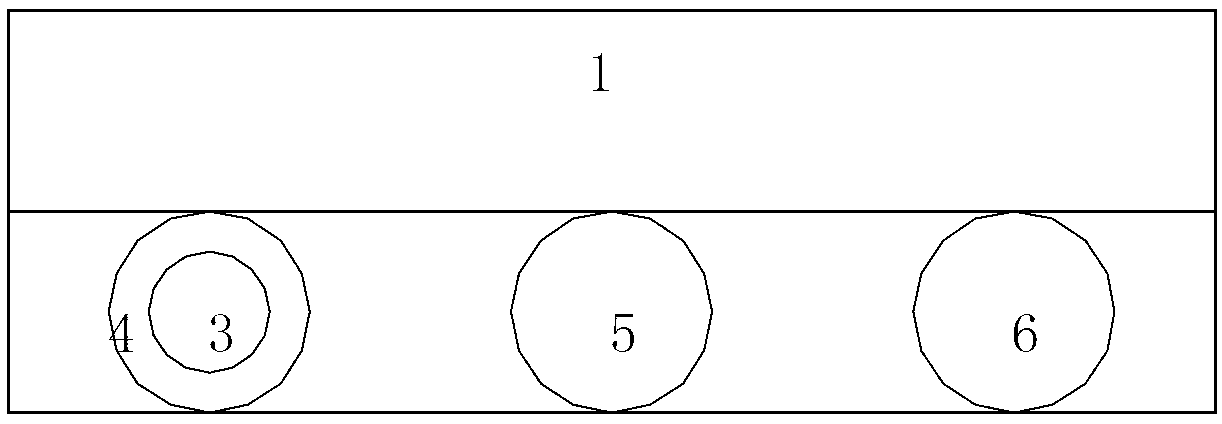

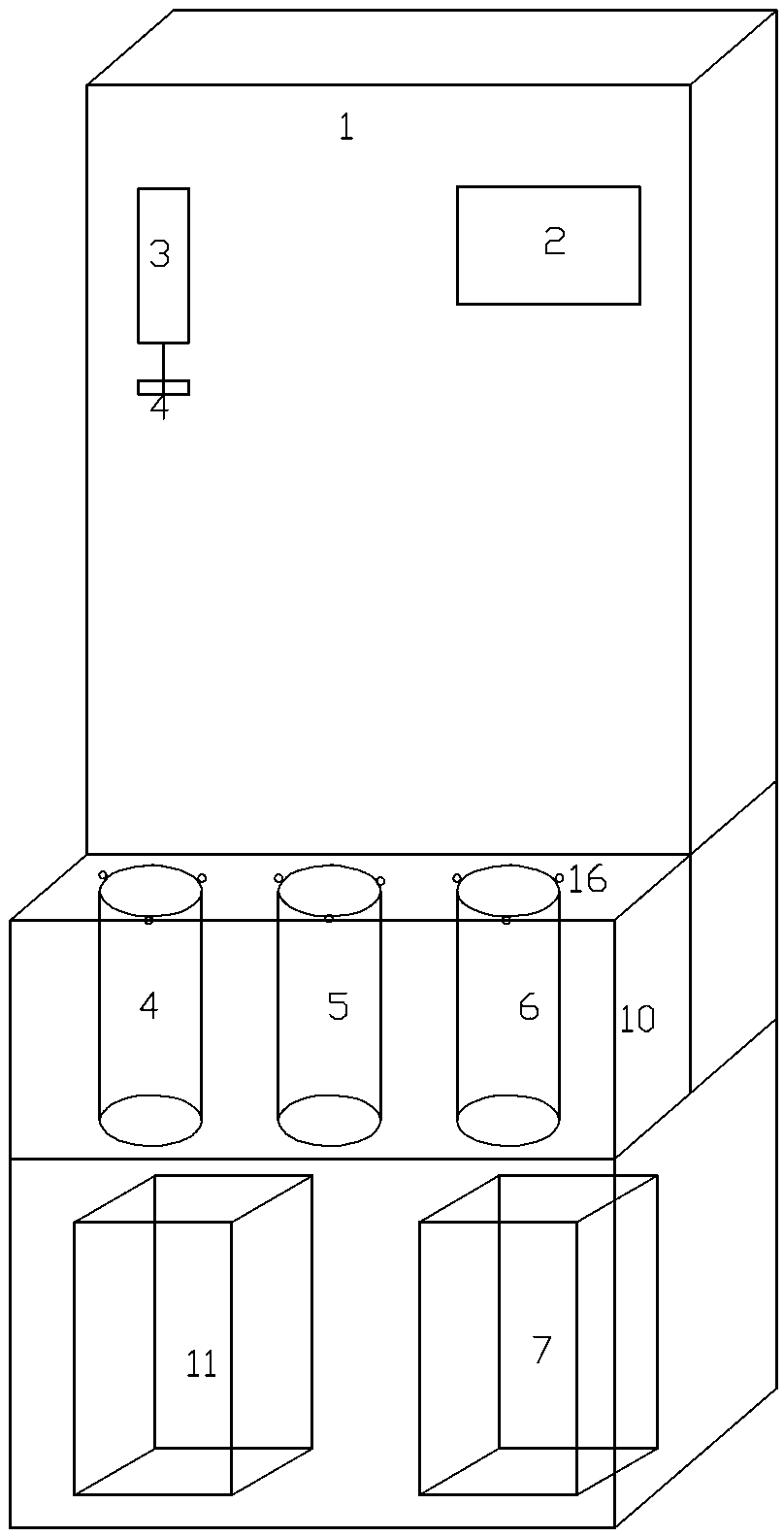

[0033] figure 1 Schematic diagram of the experimental solvent dewaxing device.

[0034] figure 1 Shown is a preferred embodiment of the invention, figure 1 The experimental solvent dewaxing device shown in includes a main frame 1, a controller 2 with a digital display, a liftable stirrer 3, a cold bath 10, and a sample cylinder 4 are installed in the main frame. The hydrocarbon oil dewaxing experimental instrument is connected with the vacuum system 11 and the refrigeration system 7 outside the device. Wherein, the vacuum system 11 is connected with the filter cylinder 6 , the cooling bath 10 is connected with the refrigeration system 7 , and the liftable stirrer 3 is installed above the sample cylinder 4 . During work, the agitator 3 moves downward, and the stirring head falls into the sample cylinder 4; after the stirring is completed, the stirring head lifts away from the sample cylinder 4; The sample cylinder 4 is installed in the hydrocarbon oil dewaxing experimental ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com