Wiring method for improving reliability of power supply system in aluminum electrolysis industry

A technology of power supply system and wiring method, which is applied in the direction of bus/line layout, etc., can solve the problems of rapid drop in temperature of the electrolytic cell, damage to the electrolytic cell, economic loss, etc., and achieve the goal of improving power supply security, reducing economic loss, and reducing workload Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

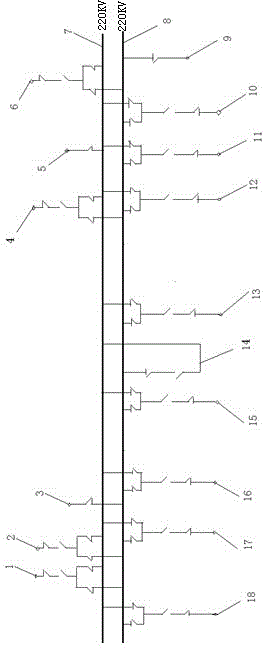

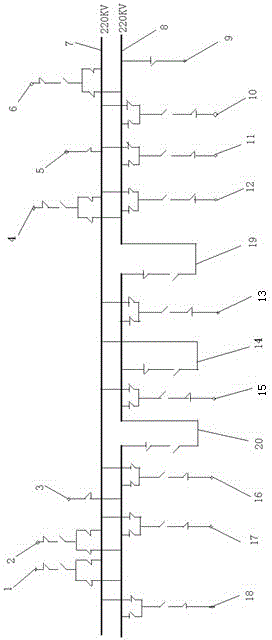

[0024] Such as figure 2 Shown, the wiring method of the present invention is:

[0025] 1. Use section circuit breaker I19 and section circuit breaker II20 on the 220kV section II bus to increase the section interval (used as a fault inspection section), so that the 220kV section II bus is divided into three section buses.

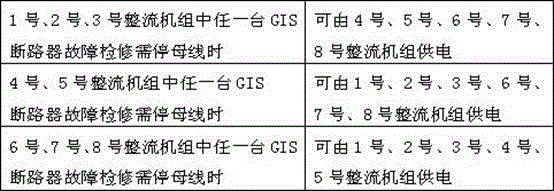

[0026] 2. Several rectifier units are connected to each section bus. No. 1, No. 2 and No. 3 rectifier units are connected to the first section bus of 220kV Section I bus and Section II bus, and the section I bus is connected with voltage mutual inductance No. 4 and No. 5 rectifier units are connected to 220kV Section I busbar and the second subsection busbar of Section II busbar, and the main busbar of Section I is connected to voltage transformer II5; No. 6, No. 7 and No. 8 rectifier units are connected to 220kVⅠ There is a set of voltage transformer III 9 on the third section bus of section II bus and the third section bus of section II bus. The group ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com