Electroacoustic transducer and manufacturing method thereof

An electro-acoustic transducer and a manufacturing method technology, which are applied to sensors, loudspeakers, electrical components, etc., can solve the problems of increasing the volume of electro-acoustic transducers, unfavorable miniaturization of end products, and waste of space for end products. , to achieve the effect of saving installation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments.

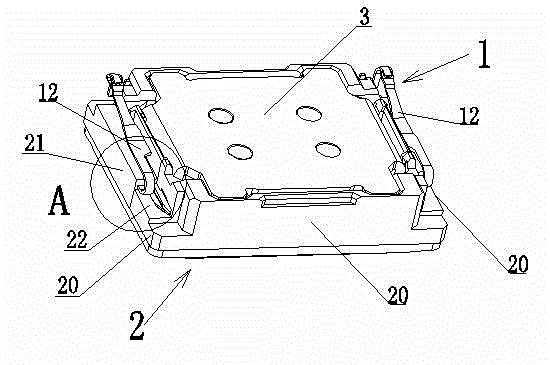

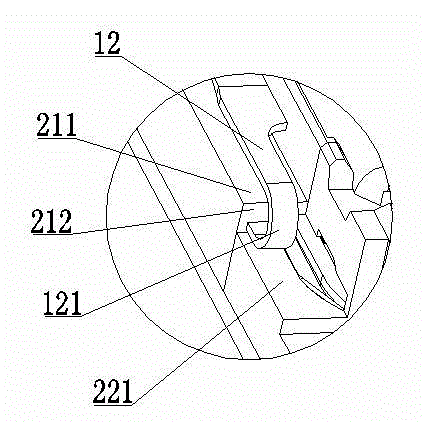

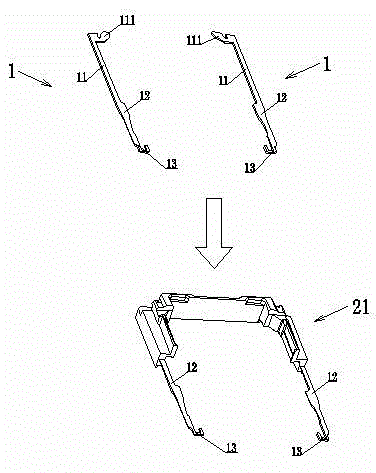

[0023] Such as figure 1 with figure 2 As shown, the electro-acoustic transducer includes a vibration system, a magnetic circuit system, and a housing 2 that houses the fixed vibration system and the magnetic circuit system, wherein the housing 2 is a hollow ring structure; the vibration system includes a diaphragm and is combined with the diaphragm Close to the voice coil on one side of the magnetic circuit system, the magnetic circuit system includes a washer, a magnet, and a basin frame 3 combined in sequence, and the magnetic circuit system forms a magnetic gap for accommodating the voice coil. The electro-acoustic transducer also includes an elastic sheet 1 combined with the housing 2, and the elastic sheet 1 is electrically connected to the internal circuit and the external circuit of the electro-acoustic transducer.

[0024] The elastic piece 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com