Method for preparing sand from high strength rocks

A high-strength, rock-based technology, applied in grain processing, etc., can solve problems such as low production efficiency, unreasonable gradation, and large product fineness modulus, reduce the amount of civil engineering and installation works, and overcome high operating costs and fine grains. degree modulus adjustable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

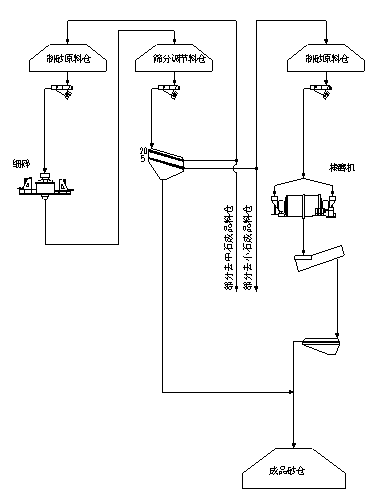

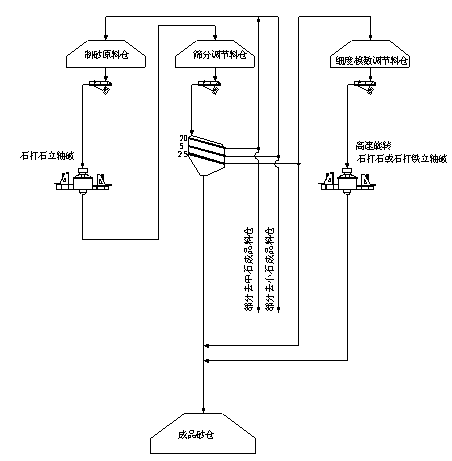

[0025] In view of the various shortcomings of the current rod mill machine-made sand, the country's emphasis on energy saving and consumption reduction, and the application of vertical shaft impact crushers in medium-breakable rocks in recent years, the present invention optimizes and adjusts traditional processes and rationally selects vertical shaft crushing equipment. In order to achieve the purpose of producing qualified finished sand.

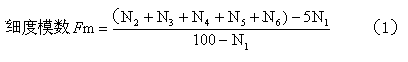

[0026] For the artificial sand and gravel production system with high strength and high abrasiveness of the parent rock, the main disadvantage of using vertical shaft crushing alone is that the product gradation is not balanced, and the fineness modulus of the finished sand is high. The fineness modulus (represented by F.M.) is the logarithmic function of the aggregate geometric mean particle size (represented by dm), that is, Fm=3.32lgdm+3,25. In a sense, the fineness modulus represents the geometric The average particle size. Therefore,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com