Ladder sand making system

A stepped and stepped technology, applied in the field of stepped sand making systems, can solve the problems of unfavorable product transportation, high product cost, and far away from raw materials, etc., and achieve the effects of fewer operators, good product quality, and low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

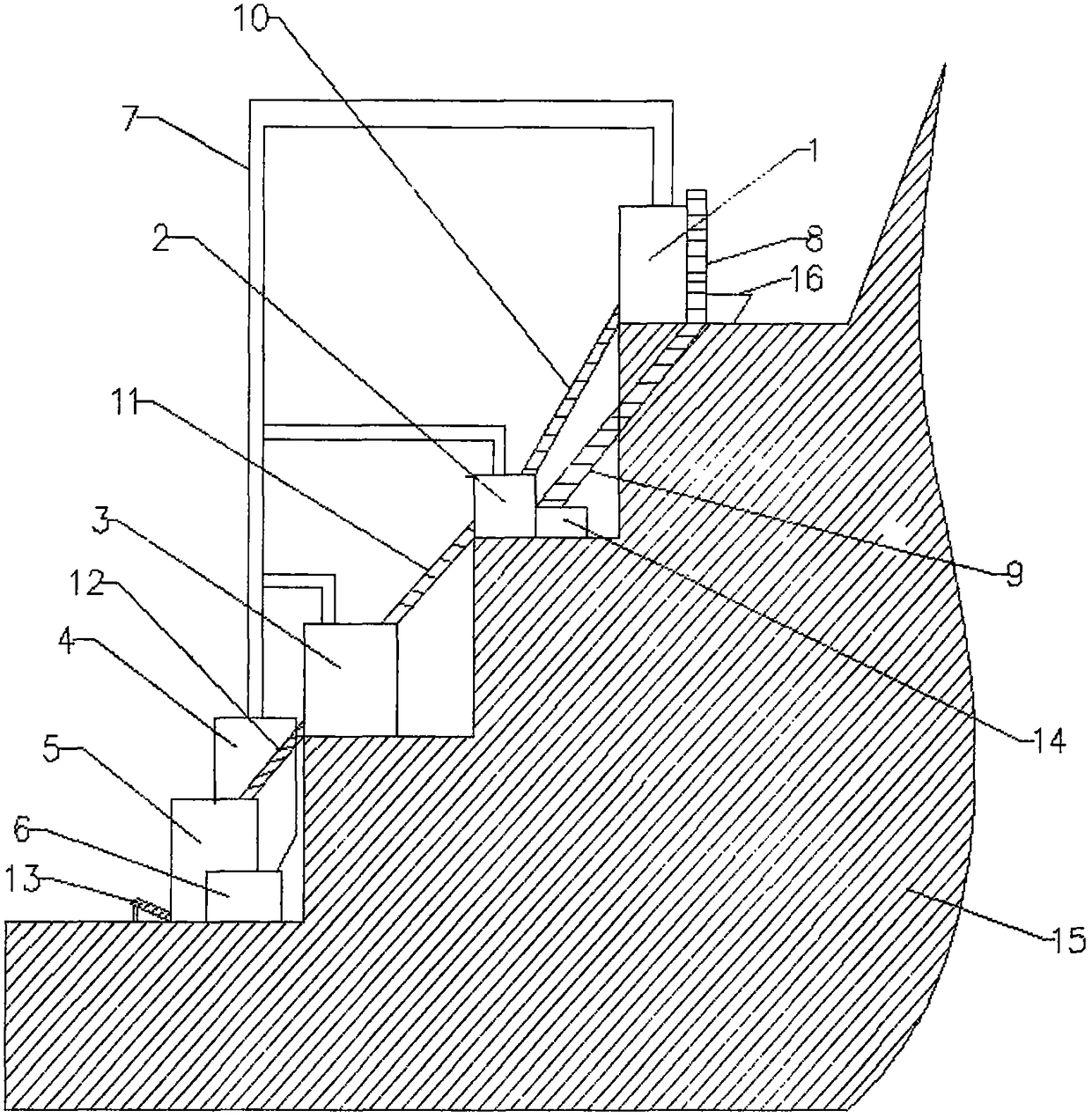

[0013] Such as figure 1 As shown, a stepped sand making system includes a feed hopper (16), a bucket elevator (8), a sand making machine (1), a vibrating screen (2), a gradation optimization machine (14), and a powder classifier (3), dust remover (4), humidifier (5), sand belt machine (13) and electrical control system (6), it is characterized in that, sand making machine (1), vibrating screen (2), graded The optimization machine (14), powder separator (3), dust collector (4), humidifier (5) and electrical control system (6) are distributed in a ladder shape from top to bottom on the mountain (15), wherein the dust collector (4), humidifier (5), sand belt machine (13) and electrical control system (6) are arranged on the first step, powder separator (3) is arranged on the second step, vibrating screen (2) and The grading optimization machine (14) is arranged on the third step, and the feed hopper (16), bucket elevator (8) and sand making machine (1) are arranged on the fourth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com