Impact crusher capable of adjusting aggregate fineness modulus

An impact crusher, fineness modulus technology, applied in grain processing, etc., can solve the problems of increased cost, low screening efficiency, low cost, etc., to prevent blockage of the mesh, and the fineness modulus of sand and gravel can be adjusted Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to better understand the technical solutions of the present invention, the embodiments provided by the present invention will be described in detail below in conjunction with the accompanying drawings.

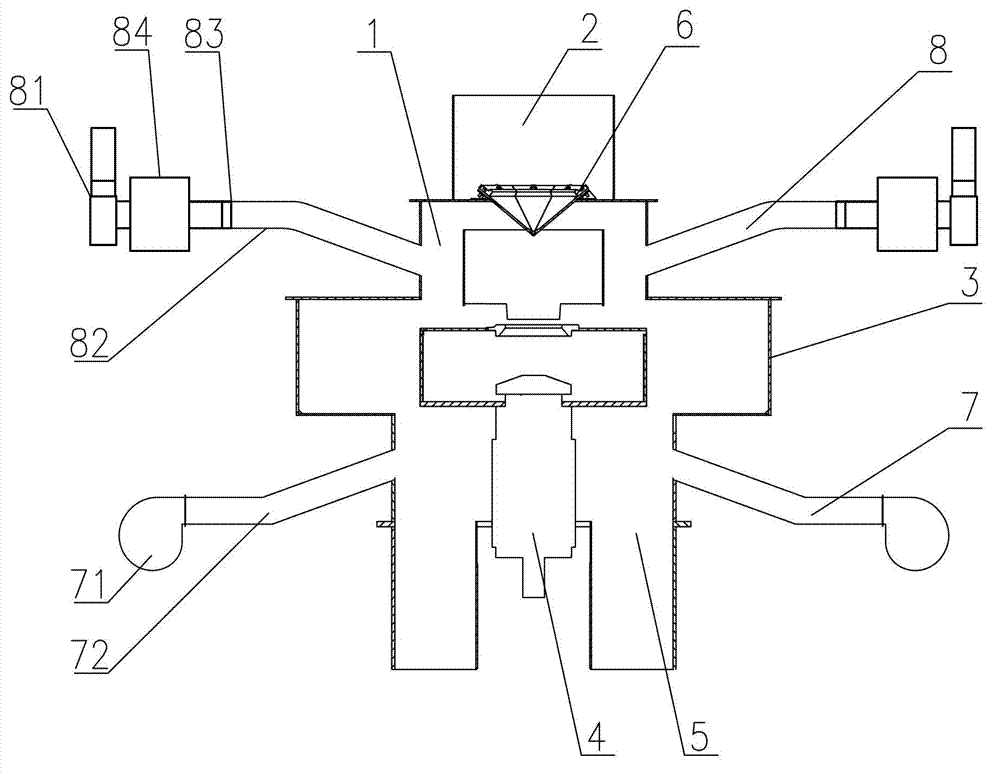

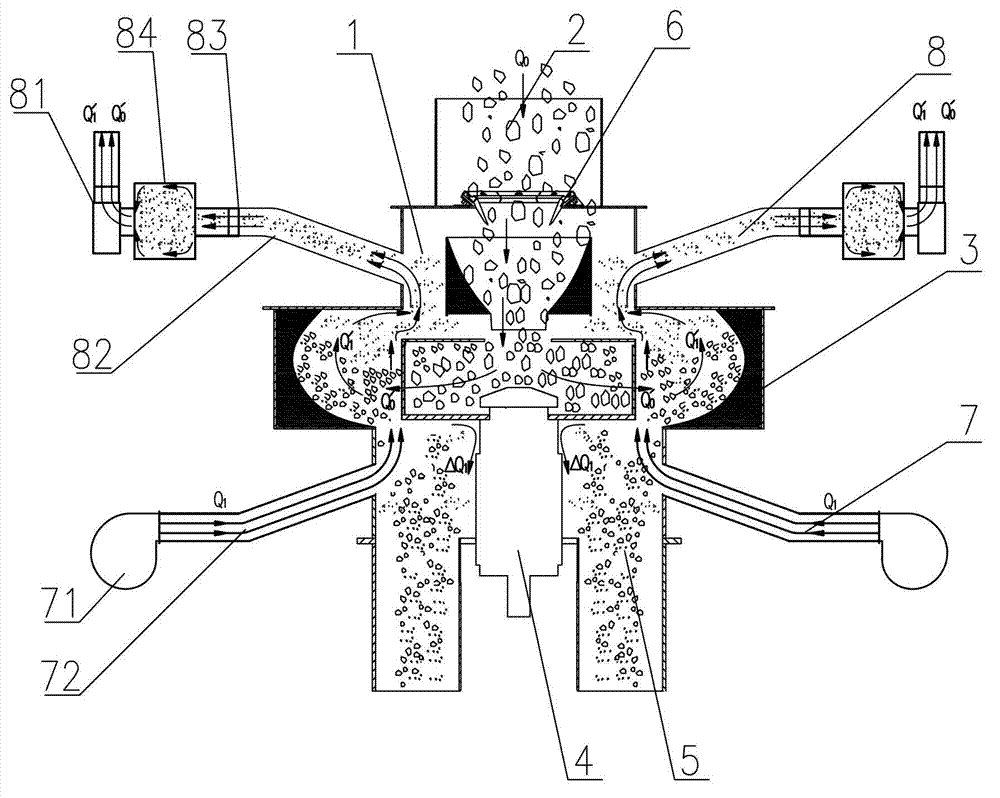

[0023] refer to figure 1 , figure 2 As shown, an impact crusher of the present invention which can adjust the fineness modulus of sand and gravel comprises a casing 1, a feeding device 2, a crushing chamber 3, a rotor 4, a discharge channel 5, a dust blocking device 6, an air flow Forming device 7, air induction device 8;

[0024] The dust blocking device 6 is composed of a plurality of rubber plates evenly arranged at the outlet of the feeding device, and is used to prevent dust from being discharged from the casing;

[0025] The airflow forming device 7 includes a blower 71 and an air inlet duct 72. The air inlet duct is arranged below the crushing chamber 3. The air inlet duct 72 is inclined upward to communicate with the crushing chamber 3. The air inlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com